BRAKE SYSTEM: FUNCTIONS, RATINGS, ELECTRONIC BRAKE (EBS), BRAKE FLUID

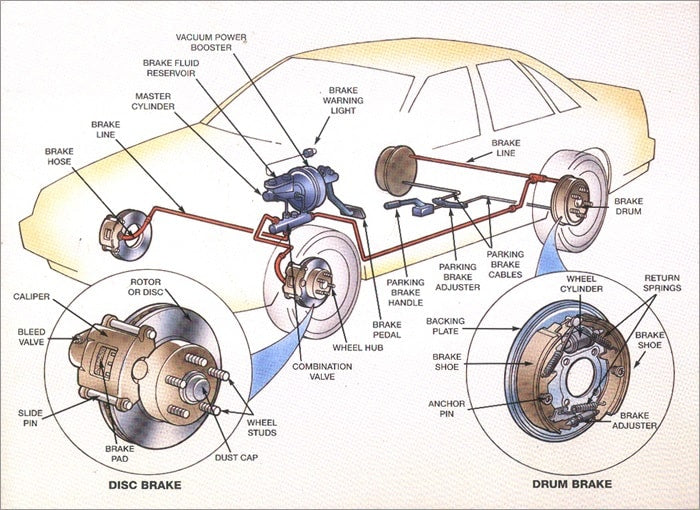

The brake is one of the most important control components of the vehicle. We have already heard about drum brakes and disc brakes. Drum brake is widely used in automobile. Brakes are necessary to stop the vehicle in the shortest possible distance or to slow down the vehicle when necessary. Without the brakes we cannot control the speed of the vehicle, which is why it is the most important system in automobiles. All brakes work on the same principle, converting the vehicle's kinetic energy into thermal energy that is dissipated in the car.

There are two most important requirements for brakes, as follows.

1. The brake must be strong enough to safely stop the vehicle at a minimum distance in an emergency. The driver must have full control of the vehicle during emergency braking and the vehicle must not skid.

2. With prolonged application of the brake, its effectiveness should not decrease. These characteristics are called anti-fade characteristics.

automobile brake system

automobile brake systemBRAKE SYSTEM FUNCTION

I. In the shortest possible time to stop the vehicle.

ii. To help control speed.

iii. To help turn around in a crowded place.

4. Keep the vehicle stopped in the presence of the operator after it has been placed at rest.

TYPES OF BRAKES

Brakes are one of the most important elements of the automobile. There are many types of brakes available in the automobile industry. These are primary brakes, secondary brakes, vacuum brakes, air brakes, disc brakes, drum brakes, etc. The classification of brakes is as follows.

ACCORDING TO THE OBJECTIVE:

1. Primary or service brake:

This brake is used when the vehicle is in running condition to stop or slow down the vehicle. This is the main braking system, located on the rear and front wheels of the vehicle.

2. Secondary brakes

Secondary brakes, also known as the parking brake or emergency brake, are used to keep the vehicle stopped. It is usually manually operated, also known as a handbrake. The main function of this brake is to keep the vehicle stationary when it is parked.

ACCORDING TO THE CONSTRUCTION:

1. Drum Brake:

In this type of brake, a drum is attached to the axle hub, while a back plate is mounted on the axle housing. The back plate is made of pressed sheet metal. Provides support for the expander, anchor and brake shoes. It also protects the drum and shoe assembly from mud and dust. Also known as a torque plate because it absorbed all of the shoe's torque reaction. Two brake shoes are mounted on the back plate with friction linings. One or two retractor springs are used to separate the brake shoe from the drum when the brakes are not applied. The brake shoe is anchored at one end while at the other ends the force is applied through some brake actuation mechanism which forces the brake shoe against the rotating drum so that the frictional force is generated between the drum and the shoe and brake applied.

An adjuster is also provided to compensate for friction lining wear with use. This brake is widely used in motorcycles and cars.

2. Disc Brake:

The disc brake consists of a cast iron disc bolted to the wheel hub and a stationary housing called a caliper. The caliper is connected to some stationary part of the vehicle and is cast in two parts, each part containing a piston. Between each piston and the disc there is a friction pad held in position by retaining pins, spring plates, etc. There are provisions in the caliper for fluid to enter or leave each housing. Their passages are also connected to another for bleeding. Each cylinder contains a rubber sealing ring between the cylinder and the piston.

When the brakes are applied, the hydraulically actuated piston moves the friction pads into contact with the disc, applying equal and opposite forces to the disc. When releasing the brakes, the rubber sealing rings act as return springs and retract the pistons and friction pads away from the disc.

BASED ON POWER SOURCE

1. Mechanical Brakes

- It is the type of braking system in which the braking force applied by the driver on the brake pedal is transferred to the final brake drum or disc rotor through various mechanical connections such as cylindrical rods, fulcrums, springs, etc. stop the vehicle.

- Mechanical brakes were used in several old motor vehicles, but nowadays they are obsolete due to their lower effectiveness.

2. Hydraulic Brakes-

- It is the type of braking system in which the braking force applied by the driver on the brake pedal is first converted into hydraulic pressure by the master cylinder (for reference, read the article on master cylinder), then this hydraulic pressure from the master cylinder is transferred to the final brake drum or disc rotor through the brake lines.

- Instead of mechanical linkages, brake fluid is used in hydraulic brakes to transmit force from the brake pedal in order to stop or slow down the vehicle.

- Almost all bicycles and cars circulating today are equipped with a hydraulic braking system due to its high effectiveness and high capacity for generating braking force.

3. Pneumatic or pneumatic brakes

- These are the types of braking system in which atmospheric air through compressors and valves is used to transmit force from the brake pedal to the end drum or disc rotor.

- Air brakes are mainly used in heavy vehicles like buses and trucks because hydraulic brakes cannot transmit high braking force over longer distances and also pneumatic brakes generate higher braking force than hydraulic brake, which is the need for the heavy vehicle.

- The chances of brake failure are less in the case of pneumatic brakes as they are usually equipped with a reserve air tank that comes into action when there is brake failure due to leakage in the brake lines.

- Nowadays, high-end cars use air braking system due to its effectiveness and fail-safe ability.

4. Vacuum brakes-

- It is the conventional type of braking system in which the vacuum inside the brake lines causes the brake pads to move, which in turn finally stops or slows down the vehicle.

- Exhaust, master cylinder, brake lines, valves along with disc or drum rotor are the main components that combine to form a vacuum braking system

- Vacuum brakes were used in old or conventional trains and nowadays they are replaced by air brakes due to their lower effectiveness and slow braking.

- Vacuum brakes are cheaper than air brakes, but they are less safe than air brakes.

5. Magnetic Brakes–

- In this type of braking system, the magnetic field generated by permanent magnets is used to cause the vehicle to brake.

- It works on the principle that when we pass a magnet through a copper tube, an eddy current is generated and the magnetic field generated by this eddy current provides magnetic braking.

- This is the braking system with the least friction, so there is less or no wear.

- This is advanced technology where no pressure is required to cause braking.

- The braking response is quite quick compared to other braking systems.

6. Electric brakes-

It is a type of braking used in electric vehicles in which braking is produced by means of electric motors which are the main source of energy in electric vehicles, it is further divided into 3 types-

(i) Obstructing the brakes-

When the brake pedal is pressed on an electric vehicle equipped with a plugging brake, the polarity of the motors changes, which in turn reverses the direction of the motor and causes braking.

(ii) Regenerative Braking-

It is the type of electrical braking in which, when braking, the engine, which is the vehicle's main source of energy, becomes the generator, that is, when the brakes are applied, the energy supply to the engine is interrupted, which causes the mechanical energy of the wheels to become the rotational force of the engine, which in turn converts this mechanical energy into electrical energy, which is subsequently stored in the battery.

- Regenerative braking saves energy and is widely used in today's electric vehicles.

- Tesla Model-S provides the most effective regenerative braking.

(iii) Dynamic or rheostat braking

It is the type of electrical braking in which the resistance provided by the rheostat causes the braking itself. In this type, a rheostat is coupled to the circuit that provides the resistance to the engine responsible for accelerating or stopping the vehicle.

ELECTRONIC BRAKE SYSTEM (EBS)

Electronic activation of EBS brake components reduces response and build-up times in the brake cylinders. This, in turn, reduces the braking distance by several meters, which can be decisive in some situations. The integrated ABS function guarantees driving stability and handling throughout the braking procedure.

Benefits

• Greater braking comfort

• Greater vehicle safety

• Better brake wear

• Easier maintenance

• Electronic Stability Control (ESC), which intervenes independently to adjust engine and brake controls to reduce rollover, skidding, spinning and stabbing

• Adaptive Cruise Control (ACC) interface, with a driver alert system that automatically monitors traffic and detects the distance to the vehicle in front

• Anti-lock Braking System (ABS) and Differential Slip Control (DSR)

• Automatic Traction Control (ATC)

Characteristics

• Electronic activation of all brake system components

• Integration of the retarder and engine brake when applying the service brake

• Braking force distribution adapts to load distribution

• Brake compatibility between tractor and trailer

• Comfortable deceleration control

• Continuous self-test through integrated diagnostics and monitoring functions

BRAKE FLUID

Brake fluid is a type of hydraulic fluid used in automobile and light truck braking applications. It is used to transfer force under pressure from where it is created through hydraulic lines to the brake mechanism near the wheels. Braking applications produce a lot of heat, so brake fluid must have a high boiling point to remain effective and must not freeze under operating conditions. Brake fluid is also designed to protect against corrosion of the system materials it comes into contact with; however, these corrosion inhibitors wear off over time.

Excessive humidity is also a problem. MAP continues to seek additional information from brake fluid manufacturers and other technical experts to identify the point of vaporization that can seriously affect braking efficiency and safety.