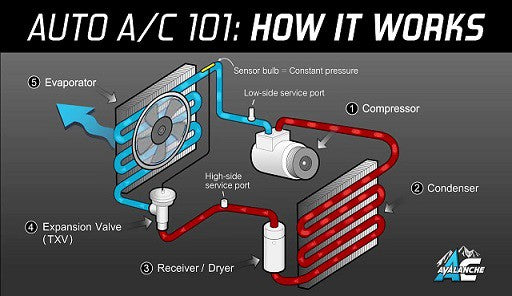

The automotive air conditioning system also works on the reverse Brayton or Rankine cycle. Like any air conditioning system, the objective of automotive air conditioning is to control the temperature and humidity of the atmospheric air and circulate it throughout the car. The automotive air conditioning system consists of a refrigeration system, an air circulation and distribution system, and a control system. The refrigeration system cools the air, which includes many other parts such as compressor, condenser, etc. The air circulation system circulates this cooled air in the car, which includes fan, air duct, etc. sensing it and controlling the cooling system.

Air conditioning has two main purposes:

1. Cools the air entering the passenger compartment

2. Removes moisture from the air so you are more comfortable inside the vehicle.

AC Car Components

It has been found that vehicles mainly have three different types of air conditioning systems. Although each of the three types is different, the concept and design are very similar to each other. The most common components that make up these automotive systems are the following:

The components used in car AC are-

1. Compressor –

It is also known as the heart of the AC system. The AC cycle begins with the compressor compressing the low-pressure gaseous refrigerant. The refrigerant exits the compressor as a high-pressure gaseous refrigerant. The compressor is the central component of the AC system. A compressor provides increased pressure to the refrigerant to convert the vapor refrigerant into liquid refrigerant, which in turn allows additional refrigerant flow through the condenser. The compressor of the car's air conditioning system is driven by the engine crankshaft via a belt.

Car air conditioning AC system Function, Components, Working

Car air conditioning AC system Function, Components, Working2. Condenser –

It is the device that looks like a small radiator and is used after the compressor, as it provides condensation, that is, it reduces the temperature of the high-pressure, high-temperature liquid refrigerant sent by the compressor through forced convection provided by the radiator fan or by separate fan used with the condenser.

As hot compressed gases are introduced into the top of the condenser, they are cooled. As the gas cools, it condenses and exits the bottom of the condenser as a high-pressure liquid.

3. Expansion valve-

It is a device used in automobile air conditioning systems to expand the high-pressure, low-temperature liquid refrigerant sent by the condenser in order to release the refrigerant pressure before sending it to the evaporator for further processing.

4. Evaporator –

It is a device that looks like another heat exchanger and is placed just behind the AC vent on the dashboard of a car, an evaporator takes heat from the passenger compartment and converts the liquid refrigerant sent through the expansion valve into vapor, which in turn delivers cooling through the fan inside the passenger cabin.

Its main function is to remove heat from the vehicle interior. A secondary benefit is dehumidification. As warmer air travels across the aluminum fins of the cooler evaporator coil, moisture contained in the air condenses on its surface.

Note – The thermal expansion valve is used in vehicles that allow the passenger to change the temperature according to need, simply by adjusting the button located on the passenger cabin panel.

5. Receiver-Dryer-

It is a safety lock used in an automobile or car air conditioning system as there is a chance that instead of vapors some liquid will also flow towards the compressor which may damage the compressor so the receiving dryer is used between the evaporator and compressor to convert this remaining liquid into vapors before sending it to the compressor for compression.

Receivers/driers perform three very important functions:

1. They act as temporary storage containers for oil and refrigerant when neither is needed for system operation (such as during periods of low cooling demand). This is the “receiver” function of the receiver/dryer.

2. Most receiver/dryers contain a filter that can trap debris that may be inside the A/C system.

3. Receivers/driers contain a material called desiccant. Desiccant is used to absorb moisture (water) that may have entered the A/C system during manufacturing, assembly or service. Moisture can enter A/C components due to moisture in the air. This is the “dryer” function of the receiver/dryer.

6. Soda –

It is a heat sensitive fluid with a very low boiling point used in AC as a heat exchange medium.

7. Pressure regulating devices

Controlling the evaporator temperature can be accomplished by controlling the pressure and flow of the refrigerant in the evaporator.

8. Orifice tube

The orifice tube, probably the most commonly used, can be found on most GM and Ford models. It is located in the evaporator inlet tube, or liquid line, somewhere between the condenser outlet and the evaporator inlet. This point can be found in a properly functioning system by locating the area between the condenser outlet and the evaporator inlet that suddenly changes from hot to cold.

9. Accumulator

Accumulators are used in systems that accommodate an orifice tube for metering refrigerants into the evaporator. It is connected directly to the evaporator outlet and stores excess liquid refrigerant. Introducing liquid refrigerant into a compressor can cause serious damage. Compressors are designed to compress gas, not liquid. The main function of the accumulator is to isolate the compressor from any harmful liquid refrigerant. Accumulators, like receiver dryers, also remove debris and moisture from a system.

An accumulator is comparable in purpose to a receiver/dryer. It serves similar but slightly different functions. An accumulator is also a metal cylinder, but it differs from a receiver/dryer in these three ways:

1. An accumulator is considerably larger than a receiver/dryer, usually about twice the volume.

2. The accumulator is connected to the evaporator outlet, in the low pressure section of the system.

3. The main function of the accumulator is to store the liquid refrigerant that leaves the evaporator, to prevent it from reaching the compressor. If liquid refrigerant enters the compressor, it can cause damage as the compressor is not designed to pump liquid, only vapor.

AC Car Working

The working of a car AC system is also almost the same as normal AC, but there is little difference.

1. Evaporator which is another heat exchanger used in AC takes heat from the passenger cabin which in turn converts the liquid refrigerant flowing through the evaporator into vapors which in turn provide cooling with the help of the fan.

2. This high temperature and low pressure vapor is then sent to the compressor which in turn increases the pressure on the vapors and converts the vapor refrigerant into a liquid refrigerant. Now the refrigerant is in a high-pressure, high-temperature liquid state.

3. This high pressure and high temperature liquid refrigerant is then sent to the condenser which reduces the temperature of this refrigerant by forced convection provided by the radiator fan or the separate fan used. Now the refrigerant is at a low temperature, but the liquid pressure is almost the same.

4. This high pressure, low temperature refrigerant is then sent to the expansion valve which in turn releases the refrigerant pressure and converts it to its original state.

5. This refrigerant is then sent back to the evaporator for the next cycle.

Note – Between the evaporator and the compressor a receiver dryer is used that converts the remaining liquid refrigerant from the evaporator into vapors before sending it to the compressor.

• The receiver dryer also provides system filtration by absorbing contaminated foreign materials within the AC system.