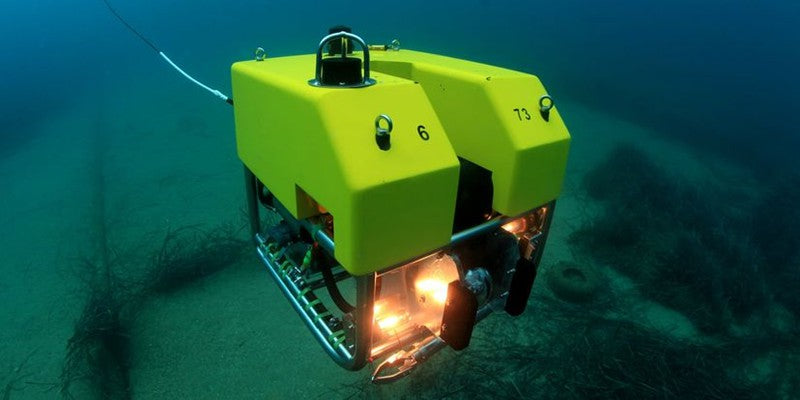

The complex process of designing and customizing remotely operated vehicles (ROVs) leverages the precision and flexibility of the CNC industry. Machining ROV parts requires attention to detail, especially the corrosion resistance of underwater aluminum housings, and the strategic selection of materials such as engineering plastics, known for their improved mechanical and thermal properties.

However, these design and manufacturing complexities often present machining challenges. In this article, we delve into the technical details of successfully deploying remotely operated vehicles underwater. Let's explore this!

Underwater ROV Design Considerations

When designing remotely operated vehicles and underwater tools, several factors must be carefully considered, including corrosion protection, material selection and surface finish.

1. Anti-corrosion in underwater aluminum housing production

Underwater ROV enclosures are one of the most important components of an ROV, protecting critical electronics and internal mechanisms. Corrosion protection is particularly important in the manufacture of underwater housings, where materials such as aluminum predominate.

To ensure the longevity and functionality of components (including structures, tools and accessories), corrosion protection typically takes a two-pronged approach: coating protection and cathodic corrosion protection, with particular emphasis on aluminum cathodic corrosion protection for underwater parts. of ROV.

Coating protection against corrosion

The susceptibility of underwater ROV parts to corrosion in marine environments requires a robust protection strategy. Coating protection in accordance with standards such as NORSOK M-501, System 7 provides an initial barrier. This method is often used on underwater structures such as ROV housings, parts and manifolds. These coatings are carefully applied to protect against corrosive marine elements.

Cathodic protection

A coating alone is not enough to provide comprehensive protection for underwater dwellings. This inadequacy calls into question the crucial role of cathodic protection, particularly the cathodic protection of aluminum. Aluminum is an effective sacrificial anode with a potential of about -1.05. When used in galvanic cathodic protection, aluminum anodes protect higher potential materials, a principle that is fundamental in customizing ROV components.

How does cathodic protection work?

The mechanics of cathodic corrosion protection of aluminum in underwater environments consists of converting active anode sites on metal surfaces into passive or cathode sites. This is achieved by supplying free electrons from a more active source – the sacrificial anodes, which are typically made from highly active metals compared to steel. In this sacrificial system, aluminum anodes corrode instead of the protected structure, significantly extending the life of the ROV housing and parts.

Understanding the electrochemical processes underlying this protection is critical to the design of ROV prototypes and the development of a custom ROV. The interaction between the two different metals in the presence of an electrolyte (salt water) triggers a flow of current from the most active sites (anodes) to the least active sites (cathodes). The use of aluminum anodes in this galvanic couple is a strategic decision given their high level of activity compared to steel.

This approach ensures the structural integrity and operational efficiency of the ROV, allowing it to perform complex tasks in demanding underwater environments.

2. Improving the performance of underwater ROV tools with engineering plastics

In the field of remotely operated vehicle (ROV) design, the use of engineering plastics, particularly polyoxymethylene (POM), is critical to improving the performance of underwater ROV tools. Known for their light weight, corrosion resistance and durability, these materials have become essential in the construction of ROV structures, engine nozzles, camera lens domes and various structural parts.

POM is known for its robustness and long service life and is particularly suitable for use at sea. Its low-friction properties eliminate the need for external lubrication and reduce maintenance requirements for ROV equipment. Its compatibility with various underwater tools and resistance to environmental influences make it a preferred choice for ROV construction. POM's inherent properties, including toughness, impact resistance, and ability to tolerate vibration and abrasion, perfectly meet the needs of underwater ROV operations.

Technical plastics such as POM, PC, ABS and PP also offer design freedom. They enable the production of ROV parts with different colors and surface textures and offer aesthetic and functional advantages. Additionally, the electrical insulation properties of plastics protect the ROV's sensitive electronics, ensuring uninterrupted functionality during underwater missions.

Engineering thermoplastics offer a significant advantage in terms of sustainability in the marine environment. Many of these materials are recyclable, reflecting the increasing focus on environmental protection in the development and use of underwater equipment. Using recyclable materials in ROV manufacturing reduces environmental impact and supports the industry's sustainability goals.

3. Selecting the correct surface finish for ROV parts

Underwater tools must operate in extreme conditions, and surface conditions are crucial to ensuring operational efficiency. A number of critical surface finishes are used, each tailored to the specific requirements of the underwater environment.

- Anodizing: This electrochemical process, often used on aluminum components, increases resistance to corrosion and wear. It is ideal for ROV frames, ROV tools and underwater housing parts and provides a durable, non-conductive surface.

- Powder Coating: Powder coating offers excellent corrosion resistance and is used for its robustness to the harsh marine environment. It is suitable for larger ROV components and ensures durability and aesthetic appearance.

- Chemical nickel plating: This surface provides uniform coating thickness, excellent corrosion resistance and greater hardness. It is particularly beneficial for complicated ROV tools and mechanical parts that require precise dimensions and high durability.

- Ceramic coatings: Known for their exceptional hardness and thermal insulation properties, ceramic coatings are used on parts exposed to high temperatures and abrasive conditions, such as engine nozzles.

- Chromate conversion coating: This coating is mainly applied to aluminum parts and provides good corrosion resistance, electrical conductivity and a good base for later painting.

The CNC industry, with its precision machining capabilities, is instrumental in the precise application of these surface treatments. The right combination of these surface treatments contributes significantly to the efficiency, reliability and longevity of underwater ROVs.

How to customize ROV equipment components using CNC machining?

The ROV consists of an underwater propulsion system, an underwater camera system, an operating system and a main structure. The diving depth of the ROV requires materials to have sufficient strength and corrosion resistance, the longer service life requires lightweight and compact parts, and the processed parts require perfect assembly and sealing.

In this section, we share the customization case study of each type of ROV component.

1. Underwater propulsion system

The ROV's underwater propulsion system consists of propeller motors. These propellers provide the vehicle with thrust for its motion control. They offer excellent maneuverability and high propulsion efficiency, allowing direct adjustment of blade angles and rotation speeds. Generally, most ROVs have multiple engines, allowing the ROV to move in multiple directions. The components of a propeller include a drive motor, bearings, a deflector, and blades.

|

Surname |

material |

Process (prototype) |

Process (production) |

Surface Finish |

|

Drive motor (protective cover) |

ABS, PC, Nylon |

CNC processing |

Injection molding |

As edited |

|

camping |

SS316 |

CNC processing |

cast |

As edited |

|

air deflector |

ABS, PC, Nylon |

CNC processing |

Injection molding |

As edited |

|

propeller |

aluminum alloy |

CNC processing |

cast |

Grinding/anodizing |

The drive motor and baffle are made of ABS, PC and nylon, which have superior strength and impact resistance. The bearings are made of SS316 material. Stainless steel bearings are rust-resistant, have high corrosion resistance and can adapt to the deep-water environment, ensuring long service life of components.

The key to producing propeller components is the propeller itself. The propeller material can be aluminum alloy or POM, which has high strength, wear resistance and corrosion resistance, and is suitable for underwater use.

To improve the efficiency and performance of the ROV, it is necessary to ensure that the manufactured propeller has high processing precision and good surface finish and is light in weight. Propeller surface accuracy is a key factor for multiple propeller vectoring and often requires a precise five-axis connection for a perfect surface finish.

After processing, accuracy is determined by scanning surface differences with a 3D scanner. Propeller blades need to be manually polished after processing to achieve a surface roughness of less than Ra0.8 μm. A smooth surface can reduce resistance to water flow, reduce harmful friction and extend the life of the propeller.

2. Main frame

The main structure of the ROV is mainly composed of a frame, a flameproof cabin and a battery compartment, which is used to protect the internal core components.

|

Surname |

material |

Process (prototype) |

Process (production) |

Surface Finish |

|

Frame |

SS304 |

CNC processing |

cast |

As edited |

|

Pressure resistant cabin |

AL6061-T4 |

CNC processing |

cast |

Hard anodized |

|

Battery compartment housing |

aluminum alloy |

CNC processing |

cast |

Hard anodized |

The entire structure of the ROV is welded in stainless steel. The frame-like structure has a large internal space, sufficient to install other main components. SS304 has excellent corrosion resistance and resists corrosive substances in seawater. It is also very robust and durable, allowing it to withstand adverse marine environmental conditions such as high humidity, temperature fluctuations and mechanical shocks.

The pressure chamber is made of AL6061-T4. 6061-T4 precision aluminum tube is made of high-quality aluminum and offers excellent wear and corrosion resistance. Compared with other metal materials, the use of AL6061-T4 can reduce the overall weight of the ROV, thereby improving the propulsion speed and overall performance of the ROV. During the production stage, purchasing AL6061-T4 hollow tubes for processing can save material costs.

Thanks to advanced battery-powered technology, the ROV is autonomous and portable, without the need to be physically controlled by tethers. The ROV's battery compartment is made of a durable, waterproof aluminum alloy housing to protect the internal lithium battery. When fully charged, the ROV can operate normally for 8 to 10 hours.

3. Underwater Imaging Auxiliary System

The auxiliary underwater imaging system of the ROV mainly consists of an underwater camera and an imaging sonar. Underwater cameras serve as both navigation and observation/measurement devices, while imaging sonars can detect underwater terrain or complex objects using sound waves, particularly useful for avoiding large obstacles.

The underwater camera's high-resolution camera is located in the detection cabin. The front end of the detection cabin is equipped with a semicircular lens to meet the light transmission requirements of the indoor camera. Both the detection cabin and the semicircular lens are CNC machined.

| Surname | material | Process (prototype) | Process (production) | Surface Finish |

| Detection booth | Aluminum Alloy/POM | CNC processing | Pressure casting/injection molding | Hard anodizing |

| As edited | ||||

| resin | 3D printing (SLA) | Feedstock | ||

| semicircular lens | Translucent PMMA | CNC processing | Injection molding | Transparent Polish |

| Translucent resin | 3D printing (SLA) | Transparent Polish |

Before official production, we can use 3D printing and CNC machining services to test prototypes of the detection booth and semicircular lenses. 3D printing allows rapid production of prototypes to verify basic structure and dimensions. However, the processing accuracy of 3D printing is not high, and the material is relatively fragile and not resistant to printing. The transparency effect of the semicircular lens made by 3D printing is also worse than that of CNC machining. CNC machining is still required to achieve precise assembly and waterproof sealing.

Through prototyping using CNC machining, the detection chamber can be made of aluminum alloy or POM. POM and anodized aluminum alloys have high strength, wear resistance and corrosion resistance, suitable for high-pressure underwater environments. In order to be able to integrate a variety of acoustic and optical sensors, the detection cabin module structure is compact; At the same time, precise assembly and sealing must be guaranteed.

Strict requirements apply to mounting surface tolerance and surface finish. The mounting surface tolerance should be ±0.025mm and the surface roughness should reach Ra0.8μm. The semicircle lens is made of PMMA material, and the surface needs to be manually polished between Ra 0.02μm and Ra 0.04μm to meet the pressure resistance and light transmittance requirements for indoor cameras.

4. Operating system

Work class ROVs can be equipped with manipulator arms for operation. Hydraulically powered manipulator arms are widely used in deepwater operations and provide robust lifting capabilities and smooth movements that improve operational efficiency and reduce labor costs. Hydraulic manipulator arms mainly consist of an arm body, a boom frame, a transmission shaft and a handle.

|

Surname |

material |

Process (prototype) |

Process (production) |

Surface Finish |

|

Arm body |

AL7075 |

CNC processing |

cast |

Hard anodizing |

|

bang |

SS304 |

CNC processing |

cast |

As edited |

|

drive shaft |

SS304 |

CNC processing |

cast |

As edited |

|

To lead |

SS304 |

CNC processing |

cast |

As edited |

The manipulator arm body is made of AL7075 material, which is known for its light weight, quick response, high strength and better corrosion resistance due to its hard anodized surface treatment. The arm frame, transmission shaft and handle are all made of SS304, which is corrosion-resistant, high strength and easy to clean and maintain. After operation, the robot arm can be cleaned with water.

Hydraulically driven manipulators are characterized by their small size, low weight, low inertia, compact structure and flexible design. The most important points when processing the hydraulically driven manipulator are the accuracy of hole axis adjustment and surface quality requirements. The hole tolerance of the robot arm transmission shaft is H7, while the surface roughness of the parts should reach Ra0.8μm. High-precision machining and smooth surfaces can reduce wear and tear on the robot arm and extend its service life.

Challenges in ROV Processing

To achieve optimal results, the development and manufacturing of underwater equipment presents several challenges that the CNC industry must face.

1. Precisely maintain durability

One of the biggest challenges in ROV design is ensuring the durability of the structure and components, given the frequent impacts and high pressure environments to which they are subjected. CNC machines excel at producing walls and corners with the highest precision, a key factor in the overall structure's resistance to harsh marine environments.

Additionally, creating custom holes and sections and maintaining proper thickness is critical to ROV durability. The precision of these processes ensures that ROV components, including the structure, can withstand repeated impacts typical of underwater exploration.

This is because bespoke holes and sections, manufactured to precise specifications, distribute stress more evenly throughout the structure, reducing the likelihood of failure under compression or impact. Maintaining the required thickness in key areas further improves the structural resilience of ROVs and ensures they remain robust and reliable during operation.

2. Adequate electrical insulation and sealing

Electrical sealing and insulation are essential in ROV manufacturing.

Engineering thermoplastics like polyoxymethylene (POM) play an important role in electrical insulation and sealing of ROVs. POM naturally has low water absorption and can maintain its integrity under pressure and in saline environments. This ensures the longevity of electrical systems and prevents water intrusion, which is critical to the operational reliability of underwater ROVs.

3. Meeting specific customer requirements

Adapting ROVs to specific operational requirements presents significant challenges. The development process typically begins with 3D modeling, followed by rigorous testing, including finite element analysis (FEA) and structural analysis. This approach identifies potential vulnerabilities and allows for adjustments before production.

Machining complex ROV parts requires the use of 5-axis integrative machines. These machines enable precise machining of complex parts, ensuring each component meets the exact specifications of the ROV's custom design. This precision is crucial for the successful integration of all functions in an ROV, ensuring its functionality and reliability in diverse underwater tasks.

Concluding

Designing and machining ROV parts requires precision, durability and customization to meet the unique challenges of the underwater environment. Addressing these challenges requires a careful approach to material selection, machining techniques and design testing. For those who wish to navigate these complexities when designing and machining ROV parts, it is highly recommended to consult experts in the field to ensure optimal performance and reliability of ROV systems.