Many plastic prototypes are milling machine parts. Normal plastics such as ABS, PC, PMMA, POM and PEEK block materials can be processed with CNC milling machines or CNC lathes. More details about the production of CNC machined parts can be found here.

If you want to make a prototype and have special material requirements, e.g. B. Transparent PC, the process is limited to CNC machining (CNC milling or turning). Of course, this part could probably also be made by injection molding. However, spending thousands or millions of dollars to produce a prototype is not realistic.

In this article I will write two true stories about selecting plastic materials inspired by real projects. (Name, company and product will remain anonymous for confidentiality reasons).

1. Color consistency between different plastic milling machine parts

An old customer came to us with a new request for a new prototype. The material requested for three of the parts is white PA6 (nylon). Two of the pieces need to be glued and polished.

However, as some people may know, nylon material is “self-lubricating” and therefore cannot be glued to other parts. In addition, polishing nylon material is not recommended because the surface of the milled nylon part will become even rougher than parts milled by CNC machines after polishing due to the material properties.

The customer then replaced two parts that needed to be glued with white PC, which can be glued (although PC parts cannot be glued firmly) and can be polished smoothly.

However, as this client places great importance on the aesthetics of this prototype, when all the parts need to be assembled and presented to important clients, the color of the parts must be consistent. The fact is that although PC and nylon materials are all white, they have slightly different shades of white. I took the following photos to show our customer the difference:

As you can see in the photos above, although they are all white, they are actually a little different. This is a small detail, but when aesthetics are really important in a prototype, for example when prototypes are going to be presented to important clients or at an exhibition, it is not a good idea to ignore the color consistency of different materials.

Back to the story: After seeing the photos, the client chose white ABS for the three pieces and was very happy with the final result of the entire piece.

2. Is there an alternative to transparent PC milling machine parts?

As I mentioned at the beginning, CNC machining is the only method to make a prototype when the material needs to be PC. But what if the prototype just needs to be transparent, can be made from any transparent material, and I want to keep the cost as low as possible?

A new client sent us some design files with a simple message: “This needs to be a clear, polished polycarbonate prototype. There is a part that must be made of clear Teflon.” (Information partially hidden for confidentiality reasons).

Since the message was quite simple and there was no block of clear Teflon (only clear Teflon inserts for injection molding), I called the cell phone number left by the customer.

After consulting, I learned that the entire piece needs to contain around 5 liters of water and that the material does not need to be PC. All parts can be made from other transparent materials. The customer wants to spend as little as possible to prototype and test that the entire product works as planned. The part doesn't need to be very transparent. It is acceptable if you can see inside the part. If it's too expensive to make the part transparent, it's okay if the piece isn't as transparent.

After getting all this information, I recommended 3D printing this part and polishing the surface with clear varnish. This is because 3D printing can be used to create many complex shapes and generally costs much less compared to CNC machining. If a part is too complex for CNC milling machines, it sometimes needs to be divided into several pieces, machined separately and glued together at the end.

In this case, as the piece needs to absorb a lot of water, it would be better not to separate the pieces because no matter how strong the glue is, there is a possibility that the glued parts will not absorb as much water as possible.

The disadvantages of 3D printing are that small transparent bubbles can form inside the printed parts, that there are very limited amounts of material available (with SLA only photosensitive resin is available) and with SLS the finished parts are quite rough. cannot be polished or painted for better aesthetics.

After a preliminary review of the designs by myself and my engineering team, we provided the customer with five processing suggestions: PC CNC milling with steam polishing, PC CNC milling without steam polishing, 3D printing with clear polishing, 3D printing without polishing , and 3D printing with just one polished part. Some sample photos were also sent to the customer to see what each piece would look like in the end.

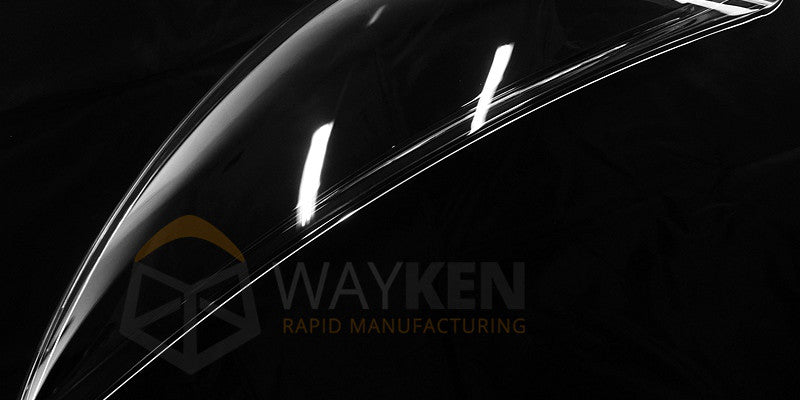

In this specific case, if the material needs to be polycarbonate, some parts would need to be split and glued together due to the structure of the project and the limitations of CNC machining itself. We present the customer with a very specific dividing and gluing plan (the piece needs to hold approximately 5 gallons of water). In addition, the surface of the milling machine's polycarbonate parts is quite blurry, not transparent, so we need to use steam polisher to make the part transparent. If clarity requirements are high, the part must be steam polished and hand polished. In this case we only offer steam polishing for surface finishing.

When we use 3D printing (SLA), we don't need to divide the parts, they can be machined as whole parts and then assembled. But the parts that have just been printed, even though they are made of transparent material, are blurry and we need to polish them by hand to make them clear.

Among the five proposals, CNC PC milling with vapor polishing is the most expensive, while 3D printing (SLA) of transparent material without polishing is the cheapest.

After seeing all of our suggestions, the client decided to 3D print and polish a part that needed to be transparent. The part works great and is now ready for injection molding.

Finally

Although the above projects are small details in selecting suitable plastic materials, we are always patient and committed to providing our customers with the best services.