Cracks were discovered in several parts of the inner wall of the reducer key hole and on the gear end face, in the circumferential direction, following gear grinding operations in a factory. The gear itself is made of 18CrNiMo7-6 material.

The production process: rough machining → carburizing and quenching + tempering → finishing (key opening, etc.).

To determine the cause of the gear crack, a series of tests and analyzes were carried out.

1. Testing process and results

1.1 Macro inspection

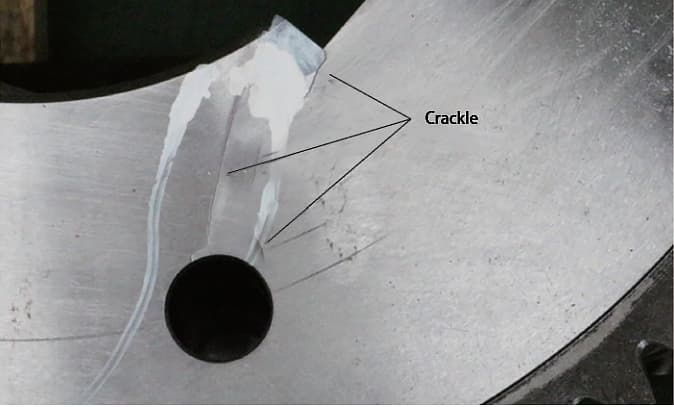

Cracks were discovered on the outer circumference of the gear, as well as in the circumferential direction of the inner bore keyhole wall and end face. In some cracks at the ends, both sides were raised, as shown in Figure 1.

By opening along the crack, the morphology of the fracture was observed. Most fissures exhibited a silvery metallic sheen of fine porcelain, and no previous fractures were identified. The root corner of the keyway was determined to be the origin of the cracks.

Fig. 1 Location and Morphology of Gear Cracks

Obvious radial patterns and tear edges can be seen around the crack source, indicating high-stress brittle fracture morphology, as shown in Figures 2 and 3.

The keyway appears rough and there is a clear trace of thread cutting.

Fig. 2 Macromorphology of gear fracture

Fig. 3 Location of gear crack source

1.2 Chemical composition inspection

The chemical composition of the gear was analyzed using an ICP (inductively coupled plasma) atomic emission spectrometer, and the results met the requirements of EN 10084-2008 Technical Delivery Conditions for Carburized Steel.

See Table 1 for test results.

Table 1 Gear Chemical Composition (Mass Fraction) (%)

| Component | W | s | P | Mn | Yes | Cr | No | Mo |

| Standard requirements | 0.15~0.21 | ≤0.035 | 0.025 | 0.50-0.90 | 0.40 | 1.50~1.80 | 1.40~1.70 | 0.25-0.35 |

| Cracked gear | 0.18 | 0.002 | 0.016 | 0.76 | 0.23 | 1.68 | 1.62 | 0.27 |

1.3 Hardness and metallographic inspection

The carburized layer of the gear is approximately 1.58 mm deep. The average hardness of the tooth surface is 725HV1, and the center hardness is 43.0HRC, all in accordance with the technical requirements of the drawing.

According to method B in GB/T 10561-2005 Determination of Content of Non-Metallic Inclusions in Steel – Micrographic Examination by Standard Grading Chart, all types of non-metallic inclusions are greater than grade 0.5.

According to the determination of the average grain size of metals GB/T6394-2017, the grain size is 6.5.

The carburized layer of the gear comprises a small amount of fine-grained carbide, coarse acicular martensite, and more retained austenite.

Based on GB/T 25744-2010 metallographic examination of carburizing, quenching and tempering in steel, carbide is classified as Grade 1, martensite as Grade 5 and retained austenite as Grade 6, which do not meet the requirements of GB/T 3480.5 -2008 Calculation of the support capacity of spur and helical gears – Part 5: Resistance and quality of materials for carburized steel surface structure and retained austenite content, as shown in Figure 4.

Fig. 4 Structure of the carburized layer (500 ×)

The sample was obtained by cutting it from the origin of the crack, polishing it and then corroding it with a corrosion solution with nitric acid and 4% alcohol.

Upon microscopic examination, a white and shiny layer was observed on the surface of the keyway, with a rough appearance, with an irregular root and microcracks present.

Figure 5 indicates that there is no carburization or decarburization on either side of the microcrack.

Fig. 5 Cutting wire with bright white layer (500 ×)

2. Analysis and discussion

The reducer gear was tested and the results indicated that the material composition, inclusion, particle size, hardness and penetration depth met the necessary requirements.

The main reasons behind gear breakdown are as follows:

1) Fast wire cutting speed leads to rough keyway, noticeable machining traces and an irregular transition fillet shape. These factors aggravate the stress concentration in the keyway, leading to the formation of a crack source. Subsequently, under grinding stress, the crack gradually expands to become a gear crack.

Furthermore, a high wire feed speed causes the formation of a white layer on the surface of the key, which contains numerous microcracks. These microcracks, in turn, lead to cracks during subsequent processes.

During the manufacture and use of parts with sharp concave corners, convex edges or notches, a significant concentration of stresses occurs at the transition of these areas. As a result, cracks can form.

In addition, rough tool marks on the machined surface caused by machine tool precision, tool edge shape and operation during part processing also contribute to stress concentration and degrade performance.

Upon inspection, the surface of the gear key was found to be rough, with visible marks from machining tools. The shape of the fillet at the root of the key was irregular, leading to a large stress concentration.

2)The surface of the keyway had a bright white layer resulting from cutting the wire. This layer is a quenching layer that contains a significant amount of residual austenite, an unstable structure that can convert to martensite and create substantial stresses. When stress builds up in the transition thread, it results in an increase in stress concentration, leading to the formation of microcracks.

In addition, the martensite needle of the carburized layer is thicker and the residual austenite content is excessive, reducing the strength of the gear and increasing its brittleness.

Furthermore, retained austenite continues to transform into quenched martensite at room temperature, generating large internal residual stresses and accelerating crack growth.

3. Conclusions and suggestions

Due to the high cutting speed of the gear wire, the surface of the key becomes rough, the shape of the transition fillet becomes irregular, and a bright white layer is generated on the machined surface. This layer intensifies the stress concentration in the keyway, forming a source of cracking. Under the influence of grinding stress and residual stress, cracks gradually expand over time.

It is recommended to mill the keyway before carburizing. If wire cutting is necessary after carburizing, the wire speed should be controlled to ensure the proper shape of the transition fillet at the root of the keyway and improve the processing quality of the keyway. If the bright white layer cannot be avoided, it must be polished and removed manually after cutting the thread.