CNC machining is a conventional manufacturing technique that uses various cutting tools to shape materials. This machining process results in the production of parts with high accuracy and precision. However, to function optimally, this machine requires proper CNC programming.

What is CNC programming? Are there different types of CNC programs? How do you ensure your CNC programming provides successful results? Keep reading, we will provide more detailed information.

What is CNC programming?

Computer numerical control programming or CNC machine programming is the process of writing code or a set of instructions that allows a computer to control CNC tools and machines to produce a part or product.

A CNC programmer examines a paper or digital CNC model of a part before inputting a series of computer instructions. To create the parts, the CNC programming computer, coupled with sensors and electrical drives, transmits these instructions to an automated machine, such as a router, router, grinder or lathe. The machine presses, crushes or cuts materials into complex shapes and surfaces under computer control.

How does CNC programming work?

Converting a design into program code for the CNC machine requires many steps. The procedure is explained step by step here.

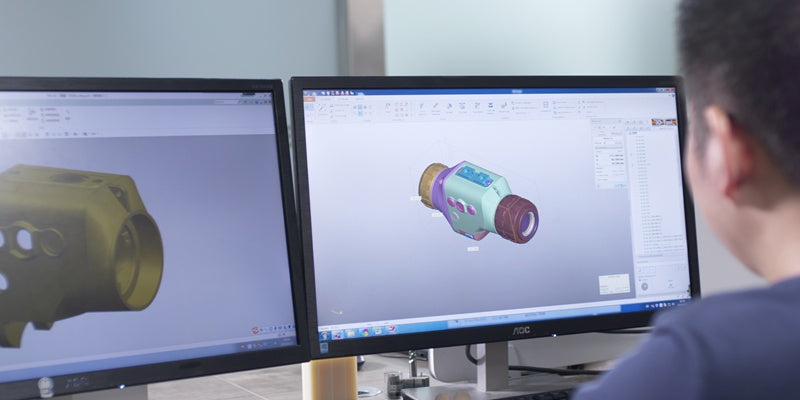

The programmer accesses the 3D or CAD model of the desired product or part, which represents the design for CNC machining.

Converting a CAD model to a CAM model using CAM software. CAM software creates toolpaths for the CNC machine. The path created depends on features present in the design, such as grooves, holes, or surface contours.

After generating the path, the CAM for CNC software also generates the machining code, also called G code.

Then, the programmer enters this G code into the CNC machine and presses the cycle start button to begin production of the part.

Types of CNC Programming

CNC programming is a general term. There are different types of CNC programming that manufacturers use to produce parts. That includes:

Manual CNC Programming

The most basic type of CNC machine programming is the manual method. Commands are manually entered into a control console associated with the CNC machine. Manual programming is ideal for machining simple parts. However, it is important to note that the process can be tedious.

Additionally, because there are no warnings or indications of possible errors, this process is often prone to errors, which can cause damage to the tool or CNC machine. Due to the high error rate, this programming method is not exactly ideal for machining complex parts.

Conversational programming

Using a CNC machine with a built-in conversational programming interface is called conversational programming. Instead of G-Code, this interface allows users to enter commands in plain English. To fully define the job, some systems ask the operator a series of specific questions.

Just like manual programming, conversational programming is best suited for simple projects. Furthermore, this CNC programming is easier and faster than manual CNC programming.

CAM Programming

Computer-aided manufacturing software is one of the most commonly used types of CNC programming, especially for CNC prototype machining. This is due to its suitability for creating parts regardless of complexity. Using CAM software for programming offers unparalleled speed and accuracy compared to manual CNC programming.

CAM software allows a programmer to visualize the tool path, ensuring potential challenges are identified during machining. Additionally, CAM software offers programmers more flexibility by allowing code to be transferred from one machine to another without having to rewrite the entire program.

List of the most important CNC codes

Although collectively referred to as G code, there are several codes used in CNC programming. These codes, identified by letters, tell the cutting or drilling tool where and how to shape the part. In addition to G Code and M Code, here is a list of other important codes of the CNC programming language.

T Codes : The T code indicates the most suitable tool for machining a specific feature on a part. In other words, it is used for tool identification.

S Codes : These S codes or speed codes indicate the desired tool spindle speeds throughout the machining process.

N Codes : Lines or blocks of N code machine code are identifiable. The CNC programmer can better organize and understand the manually created CNC code using line labels. In most cases, CAM-generated code does not require line numbers.

M Codes : Also known as miscellaneous codes. They control the non-geometric actions of the CNC machine. For example, M codes control the spindle and coolant.

G Codes : Also called geometry code. It gives instructions to the machine on how to move, when to move, where to move from, and where to stop moving.

F Codes : These are feed rate codes. They represent the different cutting speeds at which the tool must move.

D Codes : These codes describe the tool offset of a CNC machine. This can be the measurement of how far a tool extends from the toolholder or the distance between the centerline of the tool and the cutting edge.

How do I create a CNC coding?

You must be familiar with the basics of CNC machining, CAD/CAM software, and G-Code machine command language before you can create CNC code. Additionally, it is important to understand CAM software, how it works and what is expected of the programmer. Here are the easy steps to code.

1. Generate and export 3D model

To begin the coding process, it is important to first export the 3D CAD model to CAM software. However, some CAD systems have CAM software that allows you to skip this step.

2. Create the path to the tools

Manually convert CAD models into toolpaths, which works best for simple parts, or use CAM software to automatically create toolpaths. When selecting a tool, the desired characteristics of the part and the available tools must be considered.

3. Confirm toolpaths

It is necessary to confirm the correct route. This prevents machines from colliding with fixtures or workpieces. This step can be carried out manually, automatically (simulating the routes in the CAM software) or with external route confirmation software.

4. Download code for CNC machine

The final step in creating a CNC code is entering it into the CNC machine. Code transfer can occur via flash drives and other portable storage devices or by downloading directly to the machine over a local network.

Best CNC Programming Software for Beginners

Choosing the best CNC coding tool for a job depends on the intended use. Simpler software familiarizes the user with the most important variables, but advanced software offers a wide range of options and analyzes that help streamline the editing process.

The best CNC programming software programs for beginners currently on the market include:

SolidWorks® : This software is a CAD/CAM hybrid with many powerful features. However, CAM is an additional module that is often very expensive.

webcam : Due to its simplicity, this is one of the best CNC programming software for beginners. Meshcam also offers high-speed programming for simple parts.

Fusion 360® : Like Solidworks software, Fusion is a CAD/CAM hybrid. This software is packed with features. There is a free and a paid version, ideal for beginners and experienced CNC programmers. It also has a G code editor for editing codes written in other software.

Vetrico : Specifically for CNC engraving and milling applications, Vectric offers an excellent selection of software packages, including VCarve, Cut2D, and Aspire. Although a bit complex, this software allows programmers to generate, manage, and create precise toolpaths that control the CNC machine efficiently.

Mastercam : Mastercam has some CAD features, but it is still CAM software. The CAM package is powerful and easy to use. It is a popular choice for programmers as it has been on the market for over 30 years.

Industrial applications for CNC programming

CNC programming is used in a wide variety of industries. It also facilitates the manufacturing of various products, including the creation of prototypes and parts.

Health care

Hospitals can use CNC programming to create artificial anatomical parts, including joint replacements, cranial implants, and dentures. Medical devices are crucial to people's lives and health. Therefore, manufacturers can use CNC programming to test and produce advanced components for medical devices.

Consumer Electronics

In the consumer electronics sector, CNC machining and programming are used for optimal prototyping and production of laptops, smartphones and other electronic devices. Precision CNC machining makes them ideal for producing detailed parts, such as circuit boards, on a large scale.

Aerospace

The aerospace industry is one of the biggest beneficiaries of CNC programming as it facilitates the manufacturing of many parts and products. For example, propellers, wings, frames, landing gear components, and engines are all products of CNC programming.

With the help of CNC programming, participants in the CNC machining industry can produce high-quality parts with high precision, such as rotor blades for helicopters. These machines can also be used to build spacecraft such as satellites and rockets.

Auto Industry

Car engine parts such as cylinder heads, crankshafts, camshafts, valves, brackets and pulleys are manufactured by automotive CNC programmers.

They may also operate CNC machines to create parts for fluid systems, suspensions, and car interiors and exteriors. You can control CNC machines to produce components for street cars, racing cars or other forms of transportation such as buses and trains.

Tips for Successful CNC Machine Programming

Mastering proper CNC machine programming is the first step to producing products that meet industry standards. It is also a way to reduce errors and damage to the tool. Here are some tips for successful CNC machine programming.

Understand the basics

Before starting any project, you should make sure you have mastered the fundamentals of machine programming. Conservative, manual programming requires double-checking calculations to ensure the correct machine specifications are used. Remember that the accuracy of the machine depends on the accuracy of the underlying mathematics.

Adjust feed speeds

For any large-scale CNC project, operators must invest considerable time in fine-tuning a program to ensure it works correctly, effectively, and consistently. Once this is done and the application is locked, operators can “set it and forget it.” However, the manufacturing process can be optimized by adjusting certain elements of the CNC machine code.

Consider types of compensation

Just tolerating and accommodating unforeseen deviations is compensation. The most common forms of compensation must be understood by operators so they can plan accordingly.

The CNC machine's auto preset tools can be used to program compensation or accept manual input. Different types of machining compensation include fixture offsets, tool wear, cutting radius compensation, and tool length compensation.

Simplify programs

Most CNC machining applications use G codes by default. However, it can be time-consuming to program each process individually. Operators can significantly reduce programming time for machining processes by using fixed machining cycles.

How do you find the right type of CNC programmer for your needs?

Finding the right type of CNC programming for your needs is an important step toward achieving great success in CNC machining. Below are factors to consider when choosing a type of schedule.

budget

Your budget is your first guide when it comes to finding the right type of CNC programming for your needs. If you are on a tight budget, it is best to opt for types of programming such as manual and conversational, as they do not require large investments.

Skill level

Manual and dialog programming requires a high level of operator knowledge to ensure success. If you are a certified operator, these processes may be ideal for your needs. However, if you do not possess the required skills, you should opt for CAM programming.

precision level

The level of precision required is another factor to consider when choosing a type of CNC programming for your needs. If high accuracy is a priority, CAM programming is ideal because it is automated and has less chance of errors than manual and conversational programming.

Get CNC programming and machining services from Wayken

With our experience and advanced technology, we can reduce your manufacturing effort and ensure high-quality results. Contact us today and trust us with all your CNC needs.

Common questions

What does a CNC programmer do?

The task of writing CNC programs is the responsibility of the CNC programmer. The CNC programmer has two options for creating CNC code: writing it manually or using CNC programming software. In addition to writing codes, the programmer also operates the machine.

How difficult is CNC programming?

The level of difficulty in CNC programming depends on the program, its objective and the machine. For example, 3D printing is easier, while programming a milling machine to cut metal is difficult.

What language is commonly used for CNC programming?

G codes are often used in CNC programming. It is the language that CNC machines understand. It is important to note that there are smaller codes depending on the function.