Given the ability of robots to perform precision work, there is increasing demand and dependence in the medical sector. Surgical robots are designed to assist surgeons and medical professionals and improve surgical procedures. Robotic surgery allows better and more precise operations to be performed in less time.

This article explains the main requirements that must be considered when machining and manufacturing parts for surgical robots. We also provide a case study of typical machined surgical robotic components and list applications of custom robots in the medical industry.

Examples of Robot-Assisted Custom Devices

Different types of surgical robots have been developed, all aimed at different applications. They are used to enhance existing surgical treatments or robotic implantation. Below are some examples of assisted robots.

Orthopedic implants

Orthopedic implants are a type of robotic surgical device primarily used to replace a bone or joint in the human body. Examples include hip or knee replacements, etc. For each of these implants, the dimensions and tolerances must be very precise due to their diverse uses. Dimensional requirements vary from patient to patient. For each user, these implants can be custom-made using precise CNC machines, including CNC milling, EDM machining, etc.

Surgical robot

Surgical robots have revolutionized many medical procedures, offering greater precision and improving minimally invasive surgeries in various specialties. During surgery, these robots significantly complement existing procedures and facilitate the precise placement of robotic implants. In abdominal operations, for example, surgical robots play an important role in implantation, as they ensure the precise fit of the implants to each patient.

Life sciences, research and laboratory equipment

In life sciences and laboratory research, machine-made robotic devices are contributing to advances in experimental procedures and data collection. For example, robotic arms equipped with special tools help researchers with delicate tasks such as sample handling and analysis. These custom robotic devices can be built to precise specifications using CNC machining techniques, improving the efficiency and accuracy of laboratory processes.

Dental robotics

Just like exoskeleton robots, dental procedures also benefit from robotic-assisted devices. Robotic systems are used in several areas of dentistry, from dental implant surgeries to precise tooth preparations. These dental robotic systems help dentists achieve optimal results while minimizing patient discomfort and recovery times.

Robotic Imaging Components

These medical imaging devices are extremely commonly used by doctors and surgeons in robotic surgeries. They provide a magnified image of the area in question, making it easier to see the small, intricate parts of the human body. These devices must work very precisely. To achieve this, CNC machines are used to precisely manufacture each of these components.

How does precision machining work in surgically assisted robotic manufacturing?

There is no room for error in the production of parts for surgical robots. The surgical robot requires precise movements, therefore extremely precise dimensions and tolerances must be guaranteed to produce an accurate assembly.

In recent years, numerous manufacturing technologies have been introduced that enable the production of high-quality products. Thanks to the availability of modern machines such as CNC machining, EDM machining and Swiss machining, producing high-quality, precise and complex products is not a problem.

Below we list some precision manufacturing technologies for machining surgical robots.

Multi-axis CNC milling

Equipped with milling functions, these multi-axis machines enable the production of complex robotic surgical devices and robotic surgical instruments in a single configuration. This reduces manufacturing time and results in cost-effective products. As we know, milling machines work with rotary cutters that remove material by advancing the cutters along a defined path. In addition to cutting, milling processes also include drilling, reaming, etc. All processes are used to produce a surgical robotic component.

Electrical Discharge Machining (EDM)

EDM is an advanced machining process particularly suited to delivering high-precision micro-complex products without compromising quality. As an auxiliary machining technique, the process involves removing material from a part through a series of repeated electrical discharges between tools called electrodes and the part being machined in the presence of a dielectric fluid.

The processing of surgical robots involves small and complex dimensions. EDM assists in precision machining in the manufacture of parts for robotic surgery, meeting the required specifications. In this way, manufacturers avoid complications in the assembly and operation of surgical robots.

Precision turning

Precision turning is a machining operation in which the part rotates at high speed while a stationary cutting tool removes material. The result of this machining process is a cylindrical shape. Furthermore, precision turning allows parts with very small tolerances and dimensions to be machined with high precision. They are suitable for machining parts and components in the manufacture of surgical robots that cannot be manufactured by milling.

Swiss processing

It is known for producing extremely small and precise parts quickly. The machines consist of a tool that moves back and forth and creates specific shapes needed with precise measurements in the micrometer range. Due to the relatively faster processing time, response times are shorter.

Furthermore, Swiss CNC machines can perform multiple operations in one configuration, producing a batch of complex miniature medical robot parts with little or no margin for error.

Special requirements for surgical robots in metal cutting production

Surgical robots are high-precision medical devices and vital devices for surgical procedures. Typically, surgical robots are equipped with robotic arms and control centers. These components require tight tolerances in terms of dimensions and geometry. Therefore, manufacturers need to pay close attention to two aspects in the machining process of these relevant parts: how to obtain tight tolerances and how to carry out accurate inspection.

Precision and accuracy

When it comes to highly complex and intricate systems of the human body, surgical robots, robotic implantation, and robotic surgical instruments are among those manufactured and used. All of these components must be precise and accurate. Therefore, when manufacturing surgical robotic parts, precision machining must be used that can produce highly complex geometries and complicated parts with tight tolerances without compromise.

Set

Surgical robots are a group of complex robotic arm components assembled together. Therefore, it is crucial to ensure dimensions and tolerances for each part of the assisted robot. Only if each part meets strict tolerances can the robotic device be assembled perfectly. However, failure to achieve this objective can have serious consequences during operations and lead to medical fiascoes.

inspection

In addition to precision machining, inspections are equally important. In surgical robotics, there are parts of different sizes and sometimes it is very difficult to perform inspections of small parts. During manufacturing, each of these robot-assisted parts must undergo detailed inspection. Therefore, the quality department must carefully check each part on site to avoid errors later and improve assembly.

Furthermore, by ensuring product quality, production costs are saved and fast turnaround time is achieved.

Why choose precision CNC machining for custom surgical robots?

Medical devices require precise and guaranteed functionality. A small error of these robotic surgical devices during operation can cause huge costs, so there is no room for error. Furthermore, robotic dental inserts, surgical instruments and robotic arm components must be manufactured with a high level of precision and repeatability. Precise cuts and shapes must also be guaranteed.

CNC machines are known for enabling precise, high-precision machining, taking into account tight tolerances and complex geometries. Here are some of the benefits of precision CNC machining for manufacturing robot parts.

Turn around quickly

Computerized operation and the availability of multiple tools allow CNC machines to perform multiple processes in the same configuration, eliminating downtime caused by moving parts from one configuration to another. Furthermore, computer-aided operation also ensures correct machining of the product, taking into account precise dimensions and tight tolerances. This, in turn, leads to time savings for the quality department.

Precise CNC machining ensures faster and more accurate execution of manufacturing processes, resulting in faster production of a greater quantity of customized surgical robots in less time.

Consistency and quality assurance

Precise CNC machining ensures consistent, high-quality performance at every stage of production. Computerized control of CNC machines ensures that each component, whether a robotic arm or a surgical instrument, is manufactured to identical specifications.

Furthermore, it can be programmed to carry out strict quality controls during the surgical robot machining process. This real-time monitoring helps detect deviations from specified dimensions, allowing immediate adjustments and ensuring that only high-quality components are manufactured.

Versatility in materials and designs

CNC machines are available to process various materials and complex designs. Whether surgical robot components need to be machined from metal, plastic or composite materials, precision CNC machines can easily handle a variety of materials.

The ability to work with complex geometries is another advantage. Surgical robots often require different designs to fulfill the required functions. CNC machining allows these complex designs to be executed with precision, ensuring the final components meet exact specifications and perform well in a surgical environment.

Ensure assembly

To build a surgical robot it is necessary to assemble several parts. Each of these parts must fit perfectly, otherwise operation and operation could be fatal. Thanks to micro-precision and computer-aided functions, CNC machines allow each machined part to have the correct dimensions and tolerances. Therefore, the use of these machines helps in obtaining the appropriate assembly necessary for the surgical robots to perform their functions.

Cost benefit

CNC machines can utilize raw materials more efficiently, thus minimizing waste. The precision and accuracy of CNC machining ensures that each component is manufactured with minimal material waste, contributing to cost savings and environmental sustainability.

At the same time, the CNC quality department is prepared to check the production of each part at each stage and immediately identify whether rework is necessary. This way, changes are made immediately rather than re-editing the entire product later. Therefore, the use of CNC machines in the production of parts for surgical robots allows cost control and increases profitability.

How to make precision machined parts for robotic surgical devices (with housings)?

Case 1: Machining solutions for critical features and dimensions in robotic surgery parts

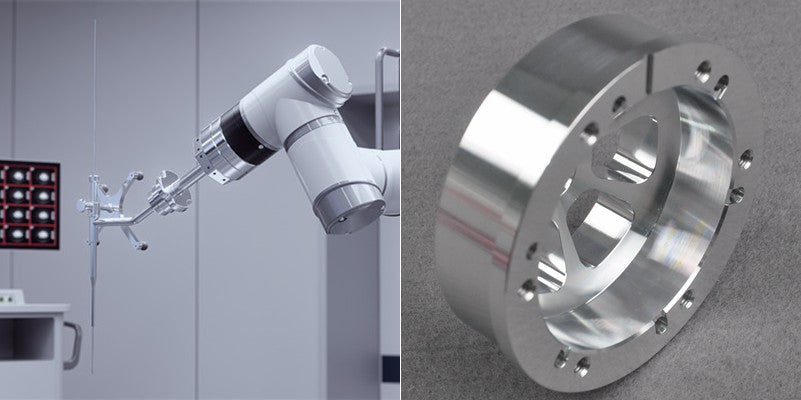

Typically, surgical robots have relatively complex mechanical structures, so some parts have tiny features that are not easy to manufacture. Here is a case study of a small robotic part for surgical equipment.

Main characteristics and dimensions

The image above shows a small stainless steel part of a surgically assisted robotic arm. The piece measures 7 x 7 x 22 mm and features sharp cuts and open grooves on the edges. As the image shows, the thickness of the cuts is extremely thin, just 0.1mm.

During the initial stages of this project, we discussed the project requirements in detail with the client. We must pay attention to producing all functions as accurately as possible, as these are crucial for the functioning of the surgical robot. As this is the crucial point for the entire project, there were many manufacturers contacted by the customer who refused to produce these robot components due to high rejection rates.

Machining Solutions

Thanks to our many years of experience and a highly qualified team, we were able to produce these small robotic parts in stainless steel and the final quality met our customers' expectations.

Case Two: How does WayKen ensure specific tolerances for precision surgical robot components?

For robotic arms for surgery, gear parts such as shafts and wrists are extremely important because many other components need to work together with the shafts. Qualified shaft parts can ensure the entire robot system works in good condition.

General concentricity during machining

Certain geometric tolerances must be guaranteed for the most important mounting components in the drive system of a surgical robot. The most important of these is concentricity. We will present a case to explain more about the subject.

As the drawing shows, there are two types of deviation – radial deviation and axial deviation. Both types of concentricity have very tight tolerances. It is well known that total deviation can control other shape and position tolerances, e.g. B. Perpendicularity, concentricity, concentricity and parallelism. Therefore, as long as the overall deviation during machining is well controlled, the other dimensions can also be guaranteed.

Processing route

As mentioned above, reference point A is the key to achieving the overall deviation for the φ2.5 hole in the part. At the same time, machining the A side of the reference point and the φ2 hole becomes a critical start. Therefore, we developed the following machining route for these machined parts for surgical robots.

The lathe used throughout the manufacturing is very precise and a special jig tool was used to clamp the part for moving the part. In any case, our engineers managed to limit the offset tolerance to 0.01 mm. Finally, the important overall concentricity for the φ2.5 hole was achieved.

For the step height (4.06 mm), continuous machining of the main cylinder body was the key to successful production. As long as the entire cylinder is completed in one pass, the second general bypass can be easily achieved.

The key to production success was the continuous machining of the main cylinder body. Any stop during the machining process could affect the cylindricity. We also constantly check the deviation when turning with a dial indicator. This also helped us ensure the final quality of the surgical robot parts.

Ensuring inspection and delivery standards

The basic problem was that the probe of the coordinate measuring machine was too large to carry out the inspection and obtain accurate results. To solve this problem, we purchased a unique probe called “STAR” from RENISHAW, which is equipped with a smaller pin head. The new inspection tool helped our final quality control work very well.

Materials available for machining robotic surgery devices

Depending on the different parts of robotic surgical devices, the materials are different. In fact, both metallic and plastic materials can be used to manufacture robotic surgical devices. Below are some examples of metal and plastic.

stainless steel

Additionally, stainless steel is suitable for high-precision machining and medical devices typically require tight tolerances.

aluminum

Besides stainless steel, aluminum alloys are the second most used material for these devices, such as AL7075-T6 and AL6061-T6. They are used to manufacture parts that need to be lighter than stainless steel and stronger, such as handles, housings and support parts.

Plastics

Compared to metals, plastics are used less in the production of surgical robots, but they are perfect for preliminary design verification. CNC, SLA and SLS are the three suitable technologies you can choose for design review.

CNC machining offers the greatest number of material options of the three technologies. For different components, ABS, Nylon, PEEK (with GF), PEI etc. are available for you to choose from. When precise tolerances are not required, SLA and SLS are more suitable methods. Because both SLA and SLS are extremely efficient and cost-effective for early design verification.

Surface finishing options for machined parts and surgical robot components

When it comes to surgical devices, practicality and safety are the most important factors to consider during surface treatment. Here we focus on aluminum and stainless steel, for which different surface treatment options are available in actual production.

Passivation is often used on stainless steel. The purpose of passivation is to apply an additional coating to the surface of the material and thus improve corrosion resistance. Speaking of corrosion protection, aluminum parts must also have the necessary oxidation protection methods. Anodizing is a good method. After anodizing, aluminum materials are coated with an additional layer of oxide that protects the part from future chemical reactions on the surface.

Considerations when choosing a CNC manufacturer for your surgical robot projects

Custom surgical robots have some defined applications, including implants, robotic surgical instruments, and dentistry. Choosing the right CNC manufacturer is crucial to the success of your surgical robot projects, as these components require high quality standards in CNC machining operations.

Materials expertise

Manufacturers must be able to produce precision-machined parts for assisted robots using a variety of materials and alloys. This can be achieved through the use of optimized processing technologies. In addition to tight tolerances, complex shapes must also be achieved, regardless of the challenge posed by the material used for medical purposes.

Comprehensive processing options

A reliable manufacturer must offer comprehensive and seamless processing options. This includes precision machining, post-processing and strict quality control. To guarantee these possibilities, precise processing devices must be available. This includes EDM machines, multi-axis CNC machines, CMM machines, etc. These machining techniques and equipment ensure that final products for surgical robots are of good quality, with tight tolerances and precise dimensions.

Finishing and assembly

Manufactured surgical robots consist of several complex parts and grouped control systems. In order for the manufactured equipment to guarantee proper functioning and functioning during its use, the manufactured parts must fit together well. CNC manufacturers must ensure that each product looks good and assembles perfectly.

Quality control

Manufactured products must meet the highest quality standards. Quality can be categorized as dimensional quality or aesthetic quality (uniformity). After processing, the product passes through an inspection department that carefully checks the dimensions and tolerances of each surgical robotic component.

In addition, CNC manufacturers must check the surface uniformity of robotic products. This ensures high-quality production that satisfies the customer while increasing efficiency and fast delivery.

WayKen Machining Capabilities for Robotic Surgery Parts and Components

As an on-demand manufacturer, we also produce diverse parts and components from a wide variety of materials and alloys, utilizing a variety of optimized manufacturing processes and machining technologies, including custom CNC machining, 5-axis milling, precision turning, EDM machining, anodizing, passivation. , etc.

Concluding

Customized surgical robots are being developed to facilitate operations, whether assisting doctors and surgeons with procedures or inserting robotic dental implants into the human body. In order to enable precise movements and movement sequences, such robot-assisted surgical instruments and devices have precise dimensions and tight tolerances, given their complex functionality.

Common questions

What are surgical robots?

Surgical robots are precise assistive devices that assist surgeons and doctors in performing complex operations such as orthopedic procedures. They are often equipped with robotic surgical equipment such as: B. a camera and a magnifying glass to magnify the body, as well as advanced and precise robotic surgical instruments such as tweezers, scalpels and computer-aided functions that enable planning and rendering.

How can CNC help with precision manufacturing?

CNC machines, also known as computer-controlled machines, allow for high-precision manufacturing. These machines are programmed to be accurate to hundredths and thousandths of a millimeter. Multi-axis milling machines, Swiss CNC machining and EDM machining are examples of processes that guarantee micro-precision machining and produce miniature parts with extreme precision.

Why is precision machining important?

Surgical robots are used on the human body, which is notoriously complex and complicated. The robotic surgical instruments used and robotic implant placement must be rigorously accurate, critically reviewed, and assured. Failure can be fatal.