Injection molding is a manufacturing process widely used in various industrial applications. The mold is an important part of the injection molding setup. It houses the cavity in which the molten material is filled and cooled until it acquires its final shape.

Due to its critical function and extreme working conditions, injection mold design is a complicated process. There are several injection mold components that engineers must consider during the design and process. In this article, we will highlight the purpose of various injection molded parts and discuss the selection of materials for their manufacture.

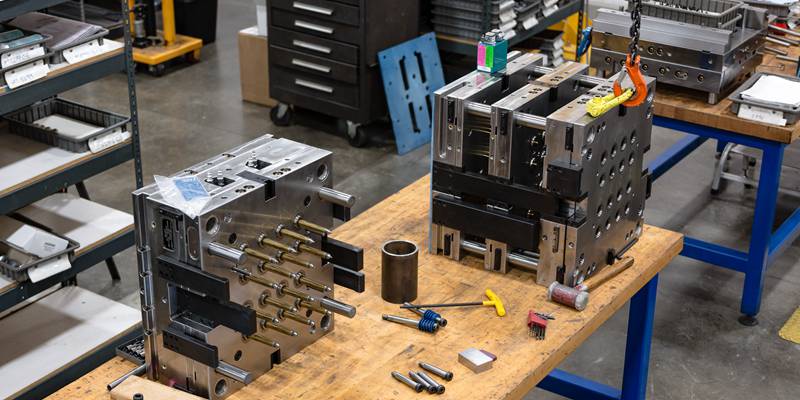

Parts and components of an injection mold

An injection mold consists of several parts, each of which has a specific function and role in the injection molding process.

Shape base

The mold base is one of the most critical injection molded parts. Other names are mold plate or mold frame. This part serves as the basic infrastructure for the entire mold assembly. Provides strength and rigidity against the enormous pressure of the injection molding process.

Furthermore, the molding box acts as a central element for integrating other components of the injection molding structure, such as the feeding unit and the cooling system. As part of this function, the molding box ensures that all components are precisely coordinated with each other. Therefore, its precise manufacturing directly impacts the precision of the part.

cavity

The cavity is the half of the mold that forms the external features of the part. By external resources we mean the resources that are visible to the user. The cavity is the component of the shape that gives the piece its surface finish and external structure.

The cavity can be mounted on the moving or stationary side of the mold.

essential

The core is the other half of the form. It is responsible for creating internal features such as holes and depressions. Surface finish may not be the most important concern for this site due to the internal features, but it is important to note that this is not a hard and fast rule.

However, design decisions such as the demolding angle are important to ensure smooth mold ejection.

Calls

Inserts are special injection mold components that are separately inserted into the cavity to create specific geometric features in the molded part. They are individual components. That is, they are not part of the core and mold cavity halves.

Before the molding process begins, an operator places the insert into the mold cavity. Support devices may be needed to keep it in place. Then the mold closes and the injection process begins.

Inserts can be made of plastic or metal if strength is required. Typically, its primary functions include creating threads in the part, creating certain surface features or textures, and reinforcing certain mold components.

Inlet nozzle and bushing

The sprue bushing and nozzle act as an interface between the mold and the feeding system. This is where the melted plastic enters the mold.

The nozzle is like a tube whose cross section narrows towards the exit point (in the molding system). The sprue bushing is the component that holds the nozzle in place and ensures its alignment and centering.

These components are important parts of an injection mold. The nozzle regulates the flow of molten plastic into the mold and ensures that it enters the mold at the correct pressure and speed. Furthermore, it guarantees a laminar flow so that the plastic can exit smoothly into the cavity.

Furthermore, this part of the injection mold also minimizes the formation of air gaps in the molten metal. It continues to inject molten metal into the cavity until most of the air within the cavity escapes the system through the ventilation system.

sprue system

The sprue bushing injects the molten plastic into the duct system. This is a distribution network that guides the molten plastic evenly and evenly into the cavity. Its function becomes particularly important when using multicavity molds, where uniform and rapid distribution of the raw material is critical to the efficiency of the molding process.

The gate system is like a road network for each cavity. At the end of the sprue there are openings for the sprue, which are important parts of the injection molding tool. They are an opening from the inlet channel to the actual cavity. Its main function is to ensure the smooth entry of raw materials into the cavity, prevent the formation of burrs and maintain uniform pressure.

Ejector pins

Ejector pins are used when the molding process is finished. After the part solidifies and is ready to be ejected, the mold opens. However, due to the pressure and surface tension between the part and the cavity surface, they stick together and require force to be ejected correctly.

This impulse comes from the ejector pins. The movable side of the mold carries these ejector pins, which only leave its surface when it retracts from the stationary part. As they are pulled back, the pins push the part out of the mold and it is ready for another molding cycle.

Ejector pin design is an important aspect of mold manufacturing. The designer must plan for a sufficient number of ejector pins to safely distribute the ejector load. Additionally, as ejector pins contact the part, their surface finish and positioning must also be considered. Generally, its position is defined at points that are not visible on the part.

Refrigeration system

The cooling system, as the name suggests, is responsible for keeping the mold temperature under control. It includes a circuit of cooling channels that circulate through the different parts of an injection mold. They mainly cover the areas close to the cavity where the melted plastic is located.

Injection molding uses water or oil as a cooling medium. Water is by far the most popular choice. However, the oil is sometimes better suited for high temperature applications. Additionally, internal baffles are also sometimes used to improve heat transfer.

Ventilation system

The ventilation system is arguably one of the critical components of an injection mold. The cavity is a closed space filled with air and gases. They form air pockets in the piece, which degrade its quality and appearance. Additionally, certain plastics also produce compounds that are unhealthy for mold.

In the ventilation system there is a network of slots, channels and pins that facilitate the exit of air from the cavity. They are held very tightly to contain the plastic inside and minimally affect the surface finish. Additionally, engineers place them at potential air trapping points, such as the divider line, to maximize ventilation efficiency.

Mold Locks

Mold locks are injection molded parts that ensure proper locking and alignment of other injection molded components. This mainly refers to the cavity and core halves of the mold. Without adequate locking, the likelihood of form defects such as burr formation, warping and dimensional errors increases significantly.

Locks can mean a number of locking features in the molding, such as pins, grooves, and grooves. They can be mechanically or hydraulically driven. Therefore, there is no specific definition for mold locks, but their general purpose is well known.

Guidance system

The guidance system ensures that the various injection molded parts are assembled in precise alignment. It consists of dowel pins and bushings in the mold halves that fit together to position the parts together.

Due to its importance in the alignment of the assembly, its manufacturing is subject to strict precision and dimensional limitations.

Common Materials for Injection Molded Components

In the previous section, the different parts of an injection mold were explained in detail. Each part has its own function and manufacturing requirements. Therefore, the selection of materials for individual mold components may be different.

In this section, we provide a brief overview of material selection for various injection molded parts.

| Injection molded part | Characteristics | materials |

| Shape base | • Strength • Rigidity • Wear resistance • Thermal resistance |

• Tool steels (P20, H13) • Aluminum alloys |

| Core/Void | • Strength • Rigidity • Wear resistance • Thermal resistance • Surface finish |

• Tool steels (P20, H13) • Pre-hardened steel (4140) aluminum alloys |

| Nozzle/Jite | • Strength • Rigidity • Wear resistance • Thermal resistance |

• Tool steels • Hard steel alloys (nickel, beryllium copper) |

| Calls | • Strength • Machinability • Material compatibility • Thermal resistance |

• Metals • Ceramics • Reinforced polymers • Carbon fiber |

| Mold guide/lock system | • Strength • Durability • Wear resistance |

• Tool steels • Hard alloy steel |

Concluding

Injection mold components are important parts of the injection molding setup and directly affect part quality. Production designers and engineers must effectively manage and maintain injection molds to achieve the best results.

Common questions

How are injection molds made?

Injection molds are manufactured by machining. 5-axis machining is the most common technique because it can create difficult contours and reach hard-to-reach areas on molds. After processing, surface processing methods such as grinding and polishing can be used to obtain the required smoothness of the cavity surfaces.

What are the key design considerations for injection mold design?

Designing injection molds is a complicated task that requires numerous considerations. Key design decisions include material selection, gate and channel design, slope angles, wall thickness/depth relationships, tolerances, and the location of sink marks and dividing lines.

What materials are injection molds made of?

Depending on process parameters such as volume and pressure, molds are generally made from steel alloys or aluminum alloys. For less intensive work, the selection of materials may include various plastics, resins and rubbers.