Smart production has entered the manufacturing industry, and automatic production has become an effective way for companies to increase their influence, expand product scale and capture the market.

The automatic workstation design has evolved from conventional stacking, welding and handling to data collection and intelligent manufacturing, and has been developed step by step.

This post provides an analysis and explanation of the three aspects of welding automation design, which include preliminary design, fixture description, site layout, and tapping.

Welding robot selection

To successfully execute an automatic robot welding project, it is crucial to have a comprehensive understanding of the selected robot model and its performance. It is essential to consider whether there are specific regulations and requirements for information about product materials, status of incoming materials, process requirements, and inspection requirements.

Furthermore, it is essential to understand the equipment function, technical parameter information and application environment to provide a comprehensive planning scheme. Typically, a 6-axis robot is used, with the attachment utilizing 7-axis or multi-axis as the external axis, specifically designed for robot manufacturing.

Based on the welding process requirements (MIG, MAG, TIG, SUP, CO 2 etc.), size parameters (such as span length and load capacity) and structural state, the appropriate equipment model should be selected.

Related Reading: MIG vs TIG Welding

For welding the lower beam of the elevator using the MAG welding process, the ABB 1410-5/1.44 robot was selected.

See Table 1 for specific parameter information.

Table 1 welding product information (unit: mm)

| Product Description | Product information | Weld length | Weld size | ||

|---|---|---|---|---|---|

| length | height | width | |||

| Lower beam | 1400 | 276 | 431 | 954 | a2.5 |

| 122 | 276 | 431 | |||

| 1100 | 276 | 431 | |||

It is essential to select the appropriate robot model based on specific parameters and process information. For products with a maximum size of 1400 mm, the ABB 1410-5/1.44 robot model was selected, which can cover the required size range.

Furthermore, it is necessary to consider whether the repeated positioning accuracy of the robot is within the control range. This is because the repeatability of the robot determines the consistency of the welding process. The high repetitive positioning accuracy not only reflects the accuracy of the robot, but also ensures that the welding quality meets the required standards. Low repetitive positioning accuracy can result in unqualified products, leading to losses for the company.

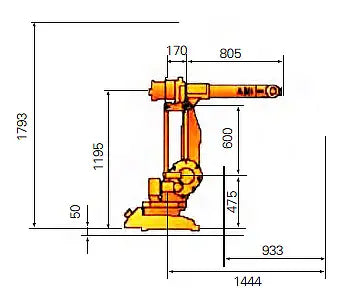

The trajectory diagram and parameter information of the robot are shown in Figure 1.

| Project description | Handler parameter information | ||

|---|---|---|---|

| Wrist holding weight | 5kg | ||

| Maximum arm span radius | 1440mm | ||

| Number of axes | 6 axes | ||

| Repeated positioning accuracy | 025mm (comprehensive average value of various robots) | ||

| Robot version | Standard Edition | ||

| Protection level | IP54 | ||

| Axial movement | |||

| Axle | Range of motion | Maximum speed | |

| 1 | +170° ~ -170° | 120°/s | |

| two | +70° ~ -70° | 120°/s | |

| 3 | +170° ~ -65° | 120°/s | |

| 4 | +150° ~ -150° | 280°/s | |

| 5 | +115° ~ -115° | 280°/s | |

| 6 | +300° ~ -300° | 280°/s | |

| Power supply: 200~600V, 50/60Hz | |||

| Robot size | Base: 620mm × 450mm | ||

| Robot weight | 225kg | ||

| room temperature | -5℃-45℃ | ||

| Maximum humidity | 95% | ||

| Maximum noise | 70dB(A) | ||

Figure 1 Robot trajectory diagram parameter information

During initial robot model selection, it is crucial to consider layout and source limitations. To ensure accessibility for welding and avoid decreasing work efficiency, it is necessary to consult the function description table and the robot trajectory diagram.

Currently, simulation and production testing can be carried out through robot teaching software. This allows assessment and confirmation of the robot's welding range, product space and position during the early stages of the project. By identifying and improving any potential issues caused by robotic production in advance, we can optimize the production process.

Description of external equipment

During the initial stages of simulation and testing, evaluation of external equipment such as tools, external shaft and sliding table is often lacking. This can lead to excessive energy expenditure in transforming these components, increasing the project cycle and causing losses to the enterprise.

Therefore, it is essential to evaluate external equipment in advance, such as tooling, external axis and sliding table.

Welding Tools

Welding tools play a crucial role in the overall progress of a project.

Tool design is a subject that requires the accumulation of experience, mechanical and electrical knowledge and in-depth product knowledge. Our goal is to provide a way to handle welding tool design.

In general, robots are suitable for standard and low-repeat products for large-scale manufacturing. Therefore, consistency in the design of welding tools, including the consistency of the robot's repeated positioning accuracy, clamping sequence, positioning accuracy, rigidity, and positioning requirements, is critical.

It is essential to ensure accurate positioning of the welding product on the tooling, as well as controlling welding stresses and deformations after welding, which requires adequate rigidity.

Most welding tools are located on pneumatic, hydraulic, electrical or manual support structures. With technological advances, magnetic clamping can also be considered, but it should only be used for special tools without magnetic polarization blowing and selected according to the actual situation.

In addition, red copper and alloy materials are often used to make special gaskets (see Fig. 2 and Fig. 3) to improve heat dissipation and rigidity of products.

Fig. 2 Special material module

Fig. 3 Copper material module

External Axis Positioner

The positioner is used as the external axis of the robot. Its positioning accuracy, rotational accuracy and rotation accuracy directly impact the repeated positioning accuracy and welding quality of the robot, which in turn affects the quality of the final product.

During the pre-design phase of the positioner with welding tool, the load needs to be considered, including the weight of the tool and the product to be welded. To avoid overweight situations, it is essential to select reducers, gears and crowns with small backlash and high rotation accuracy. This helps reduce the rotational inertia of the positioner, allowing for faster acceleration and deceleration response, ultimately improving accuracy requirements.

Table 2 presents positioner parameter information.

Table 2 Positioner parameter information

| Single Double Seat Rotary Positioner (Set) | |

|---|---|

| External axis | ABB MU200 external shaft |

| Load bearing | 200kg |

| Tool loading table height | 850mm |

| Positioner accuracy | The radius of the center of rotation is 500 mm |

| Repeated positioning accuracy | ±0.15mm |

Welding system configuration

The welding system shall include the following components in accordance with the requirements of the welding project: welding power source, wire feeder, welding gun, cooling system (some of which are integrated into the welding power source), gun cleaning system, wire cutting system, and anti-collision system.

If there are specific requirements, additional auxiliary equipment systems can be considered to improve welding quality and efficiency. These may include laser position patrol, visual tracking, source TCP calibration, and other similar systems.

Analysis of existing problems in the project

Every automation project is likely to encounter problems and challenges. In this post, we highlight some of the most common problems that arise during the routine process and explain them.

Welding tools are manual

Hand tooling is a common production mode used in some companies for welding. However, from the production point of view, the flexibility of humans is greater than that of robots, and human brains have better control than robots.

During welding, welders can adjust the process at any time by observing the weld pool and the trajectory of the welding torch. In contrast, robots follow a predetermined welding program, which can result in simple copying of hand tools and pose challenges in adjustment and tracking.

Furthermore, as robots are used for mass production, there is a risk of a large number of bad products and reworks, which can lead to inconsistencies in production efficiency.

Although the idea of tooling can be learned from hand tooling, it is necessary to consider strength and repeatability from the point of view of manufacturing needs. This can be achieved through a special process or by changing the design of the tools to meet the requirements of the robots.

Insufficient soldering accessibility

As stated previously, incomplete identification and delay in tool design prior to design evaluation led to difficulties in completing some welds during the welding process. Furthermore, some welding positions were not suitable, such as the need to switch from ship-type welding to vertical downward welding, resulting in poor welding quality products.

To solve these problems, it is necessary to carry out simulations before welding and have in-depth knowledge of the robot's instructions.

Robotic welding process selection

The robotic welding process, including welding parameters and welding sequence, differs from manual welding. The robot's output parameters are generally stable.

Copying manual welding parameters and processes to the robot may not be suitable as it may increase welding deformation. Therefore, it is crucial to reevaluate the welding process based on design considerations, given the particularity of robot manufacturing.

Welding raw materials management

The robot is highly sensitive to changes in raw materials. Therefore, when using robotic welding, we must consider the control of welding raw materials.

Therefore, it is crucial that companies and project managers understand that robots are not only capable of replacing manual work in production.

Mission completion

The robot is widely used in various industries, and welding robots are one of them. Welding robots have their own unique characteristics compared to other types of robots.

To improve the efficiency and quality of a company's products and reduce labor intensity through robotic workstations, it is necessary to pay attention to raw material management, equipment selection, process confirmation, personnel training and other aspects .

However, from a business perspective, preparing and manufacturing automation solutions is not an overnight process. Its influence and significance are not limited to the replacement of humans by machines, but also include the modernization of the entire industry. This involves investing in technology and experience and returning it with quality and market value.