Modern product manufacturing requires processes and techniques that ensure precision and accuracy due to the increasing complexity of product design. As a result, there is a race for development and innovation in production techniques, especially the introduction of automation.

Due to automation, CNC machining is a common manufacturing process known for its precision, accuracy, and ability to create complex product designs. This article explains the basics of CNC machining, its process, application and benefits.

What does Computer Numerical Control (CNC) mean?

Computer numerical control (CNC) involves controlling a machine tool using a microcomputer attached to the tool. The microcomputer can do this by responding to a programming language called G-Code and M-Code, which contains instructions about machining parameters such as feed rate, spindle speed, cutting tool, and coolant flow.

The microcomputer then passes instructions to the machine tool. Therefore, CNC machining does not require manual operation and is therefore suitable for producing defect-free parts regardless of the complexity of the product design.

What is CNC machining?

CNC machining is a subtractive manufacturing process that involves removing parts of a part to create a product. Instructions from a CAD model are used. The CNC machine removes parts of the part through machining operations such as turning, drilling or milling according to codes (G code and M code) retrieved from the CAD model that contains instructions on the machining parameters.

The CNC machining process is compatible with many metals, plastics, wood and composite materials. In addition to additive and formative manufacturing processes, such as 3D printing and injection molding, it is a standard process for producing parts. However, CNC machining has some advantages over these methods, such as: B. a high tolerance. Keep reading.

4 Main Steps for the CNC Machining Process

Regardless of your CNC machining process, CNC machining consists of four basic steps. Below is a step-by-step guide to how it generally works:

Step 1: Prepare a CAD model

A 2D or 3D model design of the product is created. There are many software programs suitable for this process, with AutoCAD and SolidWorks being particularly popular. Additionally, it is possible to convert 2D designs to 3D designs depending on the product requirements.

While some product designs may be simple, some CAD models may require advanced skills to create, especially for complex product designs.

The CAD model must be properly designed and easily show the operator important features such as tolerances, design lines, threads and other parameters for an effective machining operation.

Step 2: Convert to CNC compatible format

CNC machines do not understand the CAD model. Therefore, it is necessary to convert the CAD model into a CNC-compatible format so that the machine can interpret it. For this step, you can use CAM software like AutoCAD, Fusion 360, or other online software services.

This software can be converted to a CNC compatible format and instruct the CNC machine on parameters such as rotary and linear motion, cutting sequence, tool path, workpiece, machine speed, etc.

Step 3: Performing the configuration

This involves choosing the right type of CNC machine and setting up certain operations before the machining process begins. Choosing the right machine depends on the part, the complexity of the product design, and the cost. The workpiece is then mounted on the machine.

Step 4: Edit the piece

The operator installs the necessary cutting tools and begins the process. The process is automated and runs until the computer program considers it complete. During and after the machining process, machinists perform several levels of quality assurance inspection.

The important role of machinists in CNC machining

Although the CNC machining process is automated, there are CNC machinists who take care of expected and unexpected errors. Below are the important duties of CNC machinists:

- Find product specifications.

- Read plans, sketches and CAD/CAM files.

- Create CAE models.

- Align and adjust cutting tools and other machine materials.

- Install, use and disassemble CNC machine tools.

- Observe the speed of the machine.

- Inspect and test finished products for defects.

- Make sure a part is aligned with the CAD model.

Types of CNC machines

Each CNC machining process has its own machine. For example, machines for CNC milling are called CNC milling machines and machines for CNC turning are called CNC lathes. However, the type of CNC machine is more the axis on which they can move and rotate. Here are the most common ones used in parts manufacturing:

2 axis CNC machines

2-axis CNC machines can only machine a part in the X and Z axes, i.e. vertical and horizontal. Therefore, they are the simplest CNC machines used in the manufacture of parts.

3 Axis CNC Machine

3-axis CNC machines are one step ahead of 2-axis CNC machines because they can move in the X, Y and Z axes. They are the most used machines in CNC machining. However, there may be limitations when machining parts with complex designs. This is due to the lack of rotation.

4 axis CNC machines

The 4-axis CNC machine has a spindle that can move along all three axes. Simply put, the machine can move up and down, sideways and forward, and rotate along the X and A axes. All of this happens without the part moving. Due to their speed, precision and accuracy, these are the most used CNC machines for machining complex parts.

5 axis CNC machines

A 5-axis CNC machine has a spindle and cutting tool that can move similarly to a 4-axis machine. However, unlike the 4-axis machine, they can rotate along two of the three axes. They are considered the most complete multi-axis CNC machines because they can approach the part from all directions without having to manually reposition it during machining. 5-axis CNC machining allows for seamless machining of complex, precision parts.

3 common supporting software for CNC machining

Depending on the needs of the CNC machining process, one or more of the software programs listed below are used for each machining process:

1. CAD Software

CAD software allows users to create 2D and 3D models of physical components used in product development and manufacturing. Furthermore, they serve to provide manufacturers with design data. Examples include AutoCAD (2D and 3D), Inventor (3D), Blender, and SketchUp.

2. CAM Software

CAM software is suitable for creating G codes from CAD models for these CNC machine controls. Consequently, a CNC machine has automation. Prime examples include Fusion 360, SolidWorks, and AutoCAD.

3. CAE Software

CAE software allows product designers to replicate the performance of an intended product. This allows them to improve product designs and help engineers solve technical problems. Examples include finite element analysis, multibody dynamics, and computational fluid dynamics.

Different Types of CNC Machining Operations

CNC machining includes several techniques that subtractively remove a portion of a part to produce the desired product. However, the type of removal depends on the procedure. Common CNC machining operations in parts manufacturing include:

CNC Drilling

CNC drilling involves making cylindrical holes in a stationary part using a rotating cutting tool. It is an important CNC machining operation in the manufacture of products that require assembly of parts.

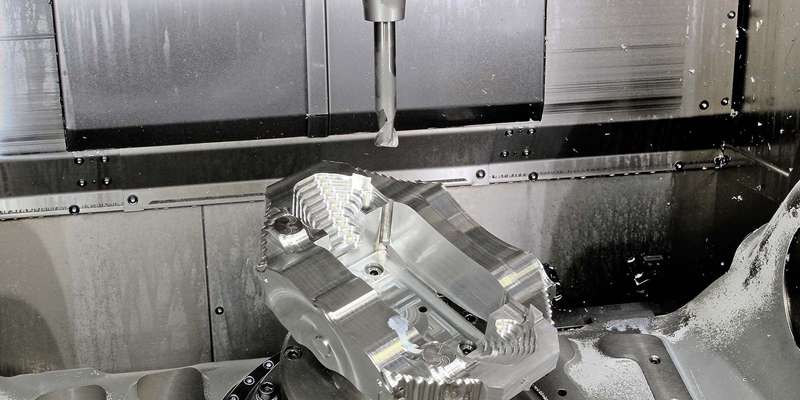

CNC Milling

CNC milling is the most common machining method that uses a cutting tool that can rotate and move along axes to remove material from a workpiece. Ease of cutting depends on the complexity of the CNC machine.

CNC turning

CNC turning is a machining process in which a product is turned and simultaneously fed to a cutting tool to produce the machined part.

Other editing operations

- Grind

- I emphasize

- Cutting

- saws

- Sharpen

Materials compatible with CNC machining

– metals : Copper, stainless steel alloys, titanium, brass, aluminum alloys, steel, magnesium etc.

– Plastics : Acetal, PEEK, Polycarbonate, Nylon, Acrylic, PVC, Polypropylene, etc.

– Composite material : Epoxy, phenols, fiberglass and carbon fiber.

– Wood : Noble wood and plywood.

– Foam: Hard, sculpted foam.

CNC machining is compatible with many materials. However, before choosing a CNC material, you should consider the following:

- toughness

- Mechanical properties

- Partial functions

- Dimensional tolerance

- operating temperature

- Cost

What are the advantages of CNC machining?

CNC machining is widely used in the manufacture of industrial parts due to several advantages. Below are some advantages of the process over other manufacturing processes.

Accuracy and precision

CNC machining is precise and allows product manufacturers to produce parts according to the intended design. Furthermore, it has high precision and tolerance; therefore, you can produce different batches of a product without losing precision. Additionally, an automated process reduces errors during processing.

Fast and efficient

You can receive a CNC machined part in just a few days. So it's about production efficiency. However, speed and efficiency depend on the type of CNC machine and the complexity of the product.

Cost effectiveness

CNC machining has high initial investment costs. However, operating costs are lower. Furthermore, the high production rate, little or no human error, and low production costs increase cost efficiency. Additionally, most machining operations require less training and most training is available online.

Best skills

Most CNC machines can carry many tools for different purposes. Additionally, they have sophisticated software that allows them to work on a variety of complex products and parts. Therefore, they have improved capabilities and compatibility with parts of different sizes, shapes or textures.

Large selection of compatible materials

Machining operations are compatible with a large material base. Common examples include metal, plastic, and composite materials.

Alternative manufacturing processes to CNC machining

CNC machining is a versatile process widely accepted in the manufacturing of parts and products. However, sometimes it is not necessarily the best method. Here are several alternative methods you can consider:

3D printing

3D printing is an additive manufacturing process that melts, deposits and solidifies a material according to instructions from a CAD or 3D digital model. Just like CNC machining, it is automated. However, unlike CNC machining, it is more suitable for simple projects.

Injection molding

Injection molding is a plastic manufacturing process in which material is melted and injected into a prepared and solidified mold. It works by the same mechanism as other manufacturing processes, e.g. B. Blow molding, overmolding and insertion molds. It is an important part of mass production of products.

cast

Die casting is similar to injection molding. However, it is suitable for metals such as aluminum. The metal is melted and injected into a prepared mold. The injection molding process can be low or high depending on the quality of the product.

A Brief History of CNC Machining

Before the electronic age, designers created parts by hand or with manually operated machines. The manufacturing processes used at that time were limited in terms of accuracy, precision, suitability for complex products, and most importantly, mass production of products. Therefore, there was research and development to introduce new manufacturing processes.

John T. Parsons had his first insight into numerical control in collaboration with MIT in the 1940s, when he developed numerical control machines in the U.S. Air Force's parts production department. These machines allow manufacturers to control a set of tools using punch card instructions. However, they still lack complete automation. Therefore, they were used in the presence of operators.

With the invention of faster computers, CNC machines began to use digital codes instead of punched cards to control machine tools. CNC machining can produce parts faster and more accurately than the previous machining system.

Concluding

CNC machining is a widely accepted process in manufacturing parts and products due to its accuracy, precision and tolerance. Therefore, it is easy for product designers and manufacturers to create products of varying complexity.

Common questions

What are Code M and Code G?

On the one hand, G codes are a series of codes that provide instructions to a CNC machine for its movements. On the other hand, the M code performs the non-cutting operations of the machine.

What are the biggest challenges in CNC machining?

Customization is not particularly easy with CNC machining. As a first step, machinists must modify CAD files to make small adjustments to finished products. Furthermore, due to technological advances, it is only possible for an experienced operator to write the programs.

In which industries is CNC machining used?

CNC machining is used in many manufacturing industries. Industries where this manufacturing process is commonly used include automotive, aerospace, military, defense, marine and medical.

What terminologies apply to CNC machining?

Common terminologies in CNC machining include:

-CAD: computer-aided software

-CAM: Computer-aided manufacturing

-CAE: Computer Aided Engineering

-DNC: Distributed numerical control

-G-Code: geometric codes

-M Code: Various machine codes

What are the trends in the CNC machining industry?

Trends in the CNC machining industry include full process automation, adding more axes to CNC machines, and developing more features for easy customization.