Taking high-power laser as an example, the parameters related to side blowing gas are studied.

For example, the relationship between the position, angle, composition and flow of side blowing gas and plasma reveals the influence law of side blowing gas on the stability and penetration of the welding process.

Compared with traditional fusion welding, laser welding has the advantages of large welding penetration, fast welding speed and small workpiece deformation.

However, in the welding process, the laser heat source with high power density will produce plasma cloud on the surface of the machined part, which will absorb and refract the laser, so that the welding energy is greatly reduced during welding deep penetration of the part. .

Therefore, in order to reduce energy loss, in industrial applications, side blowing auxiliary gas purging is generally used to suppress plasma.

In the laser welding process, the plasma is generally distributed on the surface of the workpiece and inside the small hole, and its shape and size change periodically throughout the welding process.

In the method of using side blowing gas to inhibit plasma formation, helium is the most commonly used gas.

Compared to other commonly used gases, helium has the highest ionization energy, which means it can absorb more energy before decomposition or ionization.

However, because helium is scarce and expensive, relevant experts have studied and selected new side-blowing gases or mixed gases to replace helium in many aspects.

At present, foreign researchers recommend the mixture of he:air = 3:1 based on the consideration of the stability and gas saving of the laser welding process.

In addition, in order to optimize the side blowing configuration and effectively suppress plasma in the laser welding process, researchers at home and abroad have also done a lot of research.

So far, although some of the work has focused on the way of introducing side blowing, the shape, size and position of the side blowing nozzle, some experts have also studied the influence of side blowing angle on penetration.

However, due to the difference between laser power and actual welding conditions, the corresponding research results lack universality.

In addition, the demand for further production and application also requires that this research work can reveal the essential law of side blowing in the laser welding process from the search engine, so as to effectively guide the actual production and application;

On the other hand, the hybrid laser welding process has attracted more and more attention from researchers and practical production.

In the CO2 hybrid laser welding process, the gases involved include side blowing gas required for laser welding and shielding gas required for traditional welding.

As there are many parameters in the composite welding process, users need to have a clear understanding of the mechanism of action of the gas used.

Therefore, the experience and knowledge obtained in the research of side blowing gas in laser welding are also useful for the research in hybrid laser welding.

Experimental condition

Fast axial flow 15kw CO 2 laser was used in the experiment.

The focal length of the laser was 357 mm.

The welding test plate was 20mm thick ah32 high strength marine steel.

Laser surface was used on filler wireless welding test board.

The anti-rust paint on the surface of the test plate should be removed by mechanical grinding before welding, and the oil stain should be removed with acetone before welding.

Unless otherwise noted, side-blown gas is pure helium.

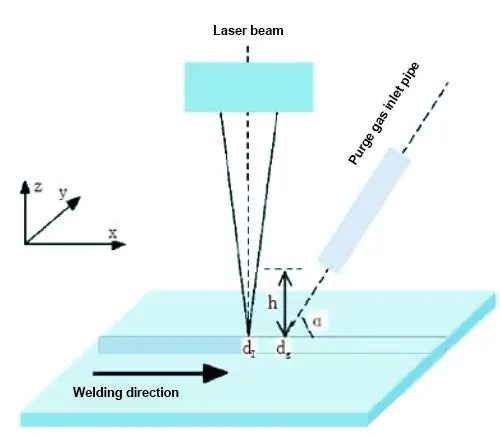

The specific experimental device is shown in Figure 1.

Figure 1 Schematic diagram of the experimental device

In the laser welding process, the plasma is synchronously recorded by the high-speed macro photography system, and the size and area of the plasma in the two-dimensional direction are calculated after welding.

Experimental process and results

1. Influence of laser power on plasma

Plasma formation increases with increasing laser power.

As can be seen from Figure 2, under the condition that the side blowing gas is also helium and the welding speed is 2m/min, the morphology and size of the plasma are very different under different laser powers.

The plasma cloud generated by high-power laser welding is more obvious.

Therefore, plasma suppression by side gas is particularly important at this time.

Laser power: 7K

Laser Power: 15K

Fig. 2 Effect of changing laser power on plasma during laser welding

2. Influence of side blow tube position on plasma

The position of the side blow tube determines the point of action between the side blow gas flow and the plasma.

Observation shows that the plasma suppression effect is different from the side blowing gas introduction position.

Figure 3 shows the changing trend of the plasma area when the gap between the side blowing gas introduction point (DG) and the laser entry point (D1) changes in the X direction.

It can be seen that the plasma is sensitive to the position of introduction of the side blow gas.

Side blowing gas position in the X-axis direction

Fig. 3 Effect of different side blow gas entry points on the plasma area

3. Influence of side blow tube angle on plasma

When side blowing is used, the selection of the side blowing gas introduction angle will also affect the plasma suppression effect.

Fig. 4 shows the corresponding plasma height change when the angle of the side blowing tube changes.

Side torch angle

Fig. 4 Effect of different side blow angles on plasma height

4. Influence of side blow flow on plasma

When different gas flow rates are used, the plasma morphology is very different.

Under the same experimental conditions (that is, the side blowing gas is helium, the welding speed is 2m/min, and the laser power is 12KW), when high-flow side blowing helium is used, the The two-dimensional size of the plasma is significantly reduced and its height and width are controlled within a very small range (as shown in Fig. 5).

Consequently, the penetration and width of the weld will also change accordingly.

With the increase of side blowing gas flow, the weld penetration will gradually increase (as shown in Fig. 6).

When the gas flow rate reaches 60L/min, penetration is significantly improved.

Therefore, in practical application, the influence of plasma can be effectively suppressed by adjusting and controlling the side blowing gas flow, so as to effectively improve penetration.

On the other hand, considering the price of lateral helium, the greater the laterally blown gas flow, the better. Instead, the optimal gas flow must be selected through cost performance evaluation.

Furthermore, the research results show that the direction of the laterally blown gas also has a direct impact on the stability of the welding process, the formation of the weld surface and its overall dimension.

Therefore, the appropriate side blowing direction should be selected according to actual needs.

a) Gas flow: 20L/AIN

b) Gas flow: 70L/AIN

Fig. 5 Effect of different side blow flows on plasma during laser welding

Gas flow (L/min)

5. Influence of gas composition on plasma

Figure 7 shows the changes in plasma with different gaseous components.

Fig. 7a shows the partial morphology of the plasma when the side blowing gas is helium, while Fig. 7b shows the partial morphology of the plasma when the mixed gas is used as the side blowing gas.

It can be seen from Fig. 7 that although the side blow used in Fig. 7a and 7b are different, the size and shape of the plasma are similar. In Figure 7C, the plasma has different shapes and the size and shape are changed.

When the mixture composition changes further, as shown in Fig. 7d, the plasma increases significantly and extends above and around the workpiece.

When the energy of the free electrons in the metallic vapor that constitutes the plasma increases, the surrounding gases undergo avalanche ionization.

At this time, the plasma expands rapidly and even splits into two, which destroys the stability of the welding process.

The different plasma forms presented in figures 7b, 7C and 7d show that it is necessary to use the appropriate mixture to guarantee its effective inhibition of plasma.

It should be noted that the side blowing gas composition can be optimized only when other gas composition parameters, such as the position of the side blowing tube, are optimized.

(A: helium; B, C and D: mixture of helium and argon)

Fig. 7 Plasma variation under different side blow gas compositions

Experimental analysis and discussion

1. Effect of side blow gas system parameters on plasma

When side blowing gas is selected to suppress plasma in the laser welding process, the parameters involved in the side blowing gas introduction system, such as the position of the side blowing tube in a three-dimensional direction, the parameters involved in the side blowing gas introduction system, such as the position of the side blowing tube, the side blowing gas introduction angle, the geometric size and shape of the side blowing tube all have an impact on plasma formation.

Thus, it has an impact on the process and results of laser welding.

Taking Figures 3 and 4 as an example, the position and angle of the side blow tube have an impact on the area and height of the plasma.

Relevant experts pointed out that the height and area of the plasma reflect the absorption and refraction of the plasma to the incoming laser.

When the position of introducing the side-blow gas changes, the change in plasma height and area can reflect the degree to which the parameters of the side-blow gas affect the laser absorption or scattering.

Therefore, by observing the plasma behavior in real time, we can study and optimize the parameters of the side blowing gas introduction system, effectively suppress the plasma and improve the laser energy for welding.

- Effect of side blow gas composition and flow on plasma

Based on the optimization of the side blow gas introduction system, the composition and flow of the side blow gas can also be optimized for the actual welding task.

This can not only achieve a stable welding process but also ensure savings.

As shown in Fig. 7, the selection of an appropriate mixture can also play a role equivalent to pure helium, and the negative gas economy is greatly improved.

However, different side blowing gas compositions (as shown in Fig. 7D) can lead to strong plasma explosion behavior, so it is impossible to guarantee a stable welding process.

Recent laboratory work has shown that, based on the optimization of the side blowing gas system, the selection range of the side blowing gas composition can be expanded.

Selecting the appropriate gas mixture can greatly improve economics based on ensuring welding requirements and quality.

Epilogue

In the process of high-power CO 2 laser welding, side blowing gas is widely used to suppress plasma in the welding process.

Correct selection of relevant side blowing gas parameters can make the input laser energy used more effectively in the deep penetration welding process.

Firstly, the position and angle of the side blow tube are two important parameters, which have a direct impact on the size and shape of the plasma.

Therefore, the side torch must be positioned correctly before welding.

Second, consideration should be given to selecting the appropriate composition and flow of the side blowing gas.

When the lateral gas flow increases, its inhibition effect on the plasma increases proportionally.

The appropriate gas flow must be determined according to actual welding requirements.

Furthermore, considering several factors such as process stability and price, the mixture can also be used as a side blower.

At this time, due to the change in the physical properties of the gas, the interaction between the gas and the molten pool must be considered on the basis of plasma inhibition, and the appropriate gas flow must be selected accordingly.