What is belt drive?

A belt drive is a type of mechanical transmission that transmits motion and power from the drive shaft to the driven shaft through an intermediate flexible component – the drive belt. It is commonly used in scenarios where the two axes are relatively far from each other.

Compared with other mechanical transmissions, belt drive has a simpler structure and lower cost, making it a widely applied form of mechanical transmission.

1. Working principle of belt transmission

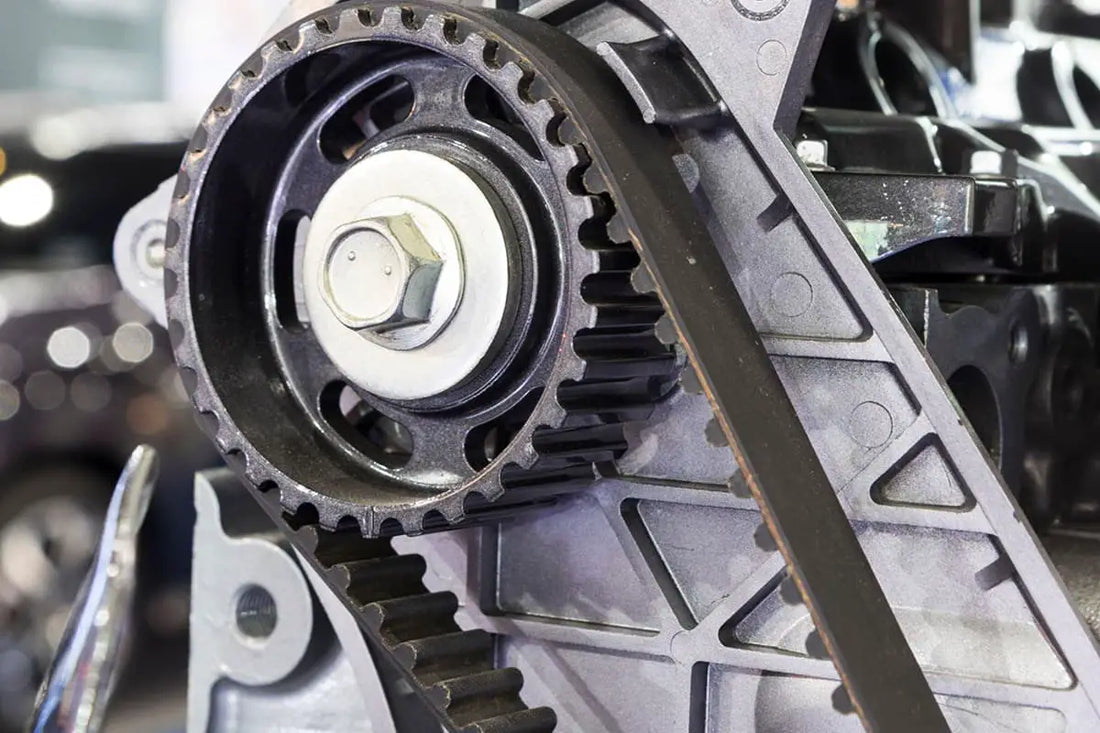

Belt transmission typically consists of a driving pulley, a driven pulley, a drive belt tightly fitted over the two pulleys, and a machine frame, as shown in Figure 8-1.

1- Driving pulley

2- Driven pulley

3- Transmission belt

2. Types of belt drives

Belt drives can be classified into friction and mesh types according to their drive principles. This article mainly discusses issues related to friction belt drives.

2.1. Friction belt drives operate by transmitting motion and power through the frictional force generated between the drive belt, which fits tightly to the pulley, and the pulley's contact surface. Based on the cross-sectional shape of the drive belt, they can be further divided into flat belts, V-belts, multi-wedge belts and round belts.

2.1.1 The cross-section of a flat belt is rectangular and its inner surface that comes into contact with the pulley is the working face. It is mainly used for long-distance transmission between two parallel shafts rotating in the same direction.

2.1.2 The cross-section of a V-belt is trapezoidal, with the two sides in contact with the pulley groove serving as working surfaces. The pulley groove is also trapezoidal. Force analysis on the surface of the wedge reveals that under equal conditions of tension and friction coefficient, the friction force generated by the V-belt is greater than that of the flat belt.

Therefore, the V-belt has greater transmission capacity and more compact structure, and is widely used in mechanical transmission. Depending on their relative width and height, V-belts can be divided into types such as regular V-belts, narrow V-belts, wide V-belts, automobile V-belts, toothed V-belts and high-speed V-belts. angle. belts. Currently, regular V-belts are the most used.

2.1.3 Multi-wedge belt, a hybrid of flat belt and multiple V-belts, combines the advantages of both and is often used in large power transmission systems where a compact structure is required.

2.1.4 The cross-section of a round belt is circular and is used only in low-speed, low-power transmissions such as sewing machines and instruments.

2.2 The geared belt drive transmits movement and power by meshing the teeth of the belt with those of the pulley. Synchronous belt transmission, as shown in Figure 8-3, is a typical example.

In addition to maintaining the advantages of friction belt transmission, synchronous belts also offer high power transmission, precise gear ratios, and are often used in situations that require smooth transmission and high precision, such as in engravers, food mixers, machines- CNC tools and textile machines. The cross section of a synchronous belt is rectangular, with the inner surface of the timing belt.

Unlike the structure of a friction-driven belt, the resistance layer of a synchronous belt is mainly composed of steel cables, which results in less deformation under load. The edge of the synchronous pulley is also manufactured with an involute tooth shape corresponding to the inner surface of the belt, produced through an involute gear cutting tool generation process. Therefore, the dimensions of the pulley teeth depend on the size of the cutting tools used.

3. Features of belt transmission

The belt has good elasticity, which allows it to dampen and absorb vibrations, ensuring smooth transmission with minimal noise. During overload, the slip between the belt and pulley can prevent damage to other parts, acting as a form of safety protection. The structure of belt transmission is simple, easy to manufacture, install and maintain, with low cost.

During operation, the transmission belt may exhibit elastic slippage, so that the transmission ratio cannot be strictly maintained. The contour size of belt transmission is large, resulting in lower transmission efficiency. Therefore, belt drive generally transmits power ≤ 50 kW, with belt speeds of 5-25 m/s and a gear ratio of no more than 5. Efficiency is approximately 0.92 – 0.97.

4. Elastic slip and failure modes in belt drive

The drive belt is an elastic body that stretches under tension, and the amount of this elastic stretch varies according to the magnitude of the tension. During operation, the tight side tension (F1) exceeds the loose side tension (F2), so the elastic stretch on the tight side is greater than that on the loose side.

4.1 Elastic slip in belt drive

Elastic slip is a unique phenomenon inherent in belt transmission operations and is inevitable during the transmission belt working process. When the tension side of the drive belt enters the drive pulley at point A, the belt speed v is equal to the circumferential speed v1 of pulley 1. But as pulley 1 rotates from point A to point B, the driving force Traction experienced by the drive belt gradually decreases from F1 to F2, and its elastic extension also decreases. In other words, the drive belt is gradually shortening, causing a small relative slip backward along the face of pulley 1, resulting in a belt speed v that is less than the circumferential speed v1 of pulley 1.

Similarly, during the process where the drive belt drives the driven pulley 2 to rotate from input point C to output point D due to friction, the pulling force on the drive belt gradually increases from F2 to F1, and the elastic extension of the drive belt also increases. This means that the drive belt is gradually lengthening. At this time, a small relative forward slip occurs on the face of pulley 2, causing the speed v of the belt to be greater than the speed v2 of pulley 2. The phenomenon of belt slippage on the surface of the pulley due to the elastic deformation of the drive belt is known as elastic slip.

Elastic slippage can cause wear on the transmission belt, consequently reducing its useful life, and reducing the speed of the driven pulley, which affects the transmission ratio.

4.2 Belt drive failure modes

The main failure modes during operation of a belt drive are: belt slippage on the pulley, belt wear, and fatigue failure.

4.2.1 Sliding

Belt drives operate with friction. When the initial tension force F₀ is constant, if the effective circumferential force F exceeds the limiting friction force between the belt and the wheel surface, the belt will experience obvious and large-scale slippage on the wheel surface, a phenomenon known as Slipping.

When the belt slips, although the drive pulley continues to rotate, both the driven pulley and the belt suffer a substantial loss of speed or even stop completely. Slippage is a harmful phenomenon, as it causes transmission failure and worsens belt wear. During normal operation, slippage must be avoided.

Elastic slip and slip are two distinct concepts. Their differences are described in Table 8-1.

Table 8-1 Differences between elastic sliding and sliding

| Item | Elastic slip | Slipping |

| Phenomenon | Local belt slippage on local wheel surface | Relative slip occurs between the belt and the wheel surface throughout the contact arc |

| Causes of occurrence | Tension difference on both sides of the belt | The effective traction force reaches or exceeds the ultimate friction force between the belt and the wheel surface |

| Conclusion | Inevitable | You can avoid |

4.2.2 Belt Failure Due to Fatigue

The tension on the drive belt varies as it operates, forming an alternating tension. The higher the rotation speed and the shorter the belt, the more often the belt wraps around the pulley per unit time, leading to more frequent changes in tension. Over time, the repeated effect of alternating tension can cause the belt to delaminate and tear, leading to fatigue failure, which results in transmission failure.

5. Tensioning devices for belt drives

The drive belt, when installed on the pulley, must have a certain tension to ensure the normal operation of the belt drive. However, after a period of operation, plastic deformation of the belt can cause slack, gradually reducing the initial tension and reducing the belt's load capacity.

To control the initial tension of the drive belt and ensure the operational capacity of the belt drive, a suitable tensioning device must be used. Several commonly used tensioning devices are shown in Figure 8-11.

5.1 Periodic Tensioning Device

On belt drives arranged horizontally or moderately inclined, a tensioning device as shown in Figure 8-11(a) may be used. The position of the motor, equipped with a pulley, is adjusted using a screw to increase the central distance, thus achieving tension. The adjustment method consists of mounting the motor on a slide rail and during initial belt tensioning, the motor is pushed into the desired position by means of the adjusting screw.

On vertical or near-vertical belt drives, a tensioning device as shown in Figure 8-11(b) may be used. By adjusting the position of the swing frame (center of the motor shaft), the center distance is increased to achieve tensioning. The adjustment method involves adjusting the nut on the screw, causing the machine base to rotate around the fixed support axis to adjust the initial tension. After the position is adjusted, the nut needs to be locked.

5.2 Automatic tensioning device

Figure 8-11(c) shows an automatic tensioning device, where the motor, equipped with a pulley, is mounted on a floating oscillating frame. Using the weight of the motor and rotating frame, the pulley and motor rotate around the fixed support axis, automatically adjusting the center distance to achieve tensioning. This method is commonly used for belt drives with low power transmission and almost vertical arrangement.

Figure 8-11(e) shows a tension wheel automatically pressing the belt due to a weight, thus achieving tension. This method is often used in flat belt drives with a large transmission ratio and small center distance, and has a significant impact on belt life.

5.3. Using the Tensioner Pulley Tensioning Device

When the belt center distance cannot be adjusted, a tension pulley can be used to tension the belt, as shown in Figure 8-11(d). The tension pulley is usually installed on the inside of the slack side to allow the belt to undergo unidirectional bending. To prevent the winding angle of the small pulley from decreasing excessively, the tension pulley should be installed as close as possible to the large pulley.

6 . Specific requirements for belt drive

1. The linear speed of the V belt should not exceed 25 meters per second, and the linear speed of the flat belt is generally 10 to 20 meters per second. In special cases, it can be reduced. The linear speed of the belt can be calculated with the following formula:

V = πDn / 60 x 1000 (meters/second)

Where

- V— Belt linear speed, (meters/second)

- D— Belt pulley diameter, (mm)

- n— Rotation speed of the belt pulley, (r/min)

2. The number of times the small belt pulley passes the flat belt per second, C, should not exceed 3-5 times, and for the V belt, it should not exceed 20 times.

C = V/L (times/second)

Where L— Belt length (m)

3. The winding angle of V-belt small pulley should not be less than 120° (150° for flat belt), otherwise the diameter difference between the two belt pulleys should be reduced, the center distance should be increased, or a pressure pulley must be installed.

4. The diameter of the small pulley should not be too small to avoid excessive bending of the belt, which shortens its service life.

For flat belt drives, the diameter of the small pulley should generally be more than 25-30 times the thickness of the fabric tape.

The minimum diameter of the small flat pulley, D_min, can be calculated using the formula:

D min =C³√N/n1 (mm)

Where

- C— Calculation coefficient, C = 1150-1400

- N— Transmission power (kw)

- n1— Belt pulley rotation speed (r/min)

For V-belt drives, the diameter of the small V-belt pulley must not be less than the following values. Otherwise, the winding angle will not be sufficient and the belt will be subject to slipping and damage.

| V-belt model | O | A | B | W | D | AND | F |

| Minimum small pulley diameter (mm) | 70 | 100 | 148 | 200 | 315 | 500 | 800 |

5. The central distance of the flat pulleys must be greater than twice the sum of the two wheel diameters; the center distance of the V-belt pulleys must be greater than half the sum of the diameters of the two wheels, but must not exceed twice the sum.

6. The belt length L can be calculated by the following formula:

L=2A + π/2(D1+D2) + (D2-D1)²/4A (mm (open transmission))

In the formula, A represents the center distance between the two belt pulleys (mm), and D2 and D1 denote the diameters of the large and small pulleys (mm), respectively.

7. The initial belt tension should be tightened with a force of about 16-18 kg per square centimeter of belt cross-sectional area.

7. Selection of belt type and number of roots

1. For flat belt transmission, the cross-sectional area of the belt can be calculated based on the power used for transmission and the linear speed of the belt.

F=P/K (cm²)

In this formula,

- F – the cross-sectional area of the belt (cm²)

- P – the working tension of the belt (kg)

- P=102×N/V.

- Here, N denotes the motor power (kw) and V is the linear speed of the belt (m/s).

K represents the real effective tension, kg/cm². For rubber belts, K can be chosen in the range of 10-25 kg/cm². When the linear speed is high, the load impact is large, the initial load is large, the continuous working time is long, and the winding angle is small, a smaller value can be chosen; otherwise, a higher value may be chosen.

Based on the calculated cross-sectional area, the width and thickness of the belt can be determined. With each layer of the belt approximately 1.2 mm thick, the number of layers in a flat belt can be approximated.

2. For V-belt transmission, refer to the following table to determine the type of V-belt based on the power transmitted.

The power range applicable to various types of V-belts.

| Power Transmission (kW) | 0.4-0.75 | 0.75-2.2 | 2.2-3.7 | 3.7-7.5 | 7.5-20 | 20-40 | 40-75 | 75-150 | above 150 |

| Recommended model | O | Oh, A | Oh, A, B | A,B | B,C | CD | IN | E,F | F |

The number of V, Z belts can be calculated using the following formula:

Z = N / (Z0 * C1 * C2) ^ 0.5

Where:

- N is the transmitted power (kW);

- Z0 is the power transmitted by a single V-belt, which can be determined in the table below;

- C1 is the winding angle coefficient, determined by the belt winding angle.

| Belt winding angle a° | 180 | 170 | 160 | 150 | 140 | 130 | 120 | 110 | 100 |

| C1 | 1.0 | 0.97 | 0.94 | 0.91 | 0.88 | 0.85 | 0.82 | 0.79 | 0.76 |

C2 – Working Condition Coefficient; 0.6-0.7.

8. V-belt pulley groove dimensions.

The dimensions of the V-belt pulley groove (see figure) can be found in the table below.

Power (in kW) transmitted by a single V-belt.

| Model | D1 Belt Pulley Small Diameter (mm) | Belt speed (m/s) | |||

| 5 | 10 | 15 | 20 | ||

| O | 50~63 | 0.31 | 0.59 | 0.88 | 1.07 |

| 80 | 0.38 | 0.74 | 1.04 | 1.29 | |

| >90 | 0.42 | 0.82 | 1.14 | 1.40 | |

| A | 80~90 | 0.59 | 1.04 | 1.32 | 1.33 |

| 100 | 0.66 | 1.18 | 1.51 | 1.64 | |

| >125 | 0.81 | 1.47 | 1.87 | 2.21 | |

| B | 125 | 1.02 | 1.84 | 2.43 | 2.58 |

| 140 | 1.12 | 2.06 | 2.80 | 3.10 | |

| >180 | 1.32 | 2.41 | 3.28 | 3.94 | |

| W | 2OO | 1.98 | 3.60 | 4.80 | 5.52 |

| 250 | 2.41 | 4.45 | 6.14 | 7:00 | |

| >280 | 2.67 | 4.95 | 6.77 | 7.72 | |

| D | 315 | 3.98 | 7:00 | 9:20 am | 9.95 |

| 400 | 5.07 | 9:10 am | 12:30 p.m. | 2:40 p.m. | |

| >450 | 5.45 | 9.95 | 1:30 p.m. | 3:40 p.m. | |

Dimensional diagram of V-belt pulley grooves

When calculating the gear ratio, the pulley diameter refers to position D in the diagram and not the outer edge of the wheel. Furthermore, consider that the belt has a slippage of 1%.

V-belt pulley groove dimensions:

| Groove dimensions (mm) | Model | ||||||

| O | A | B | W | D | AND | F | |

| The | 10 | 13 | 17 | 22 | 32 | 38 | 50 |

| I | 10 | 13 | 17 | 22 | 30 | 36 | 48 |

| w | 3 | 4 | 5 | 7 | 9 | 12 | 16 |

| t | 12 | 16 | 21 | 27 | 38 | 44 | 58 |

| It is | 9 | 12 | 15 | 18 | 23 | 26 | 32 |

| Corresponding groove angle φ | Minimum V-belt pulley diameter (in millimeters) | ||||||

| 34° | 70 | 100 | 148 | 200 | 315 | 500 | 800 |

| 36° | 90 | 125 | 180 | 250 | 400 | 710 | 1000 |

| 38° | ≥112 | ≥160 | ≥225 | ≥315 | ≥500 | ≥800 | ≥1250 |