What is additive manufacturing?

Additive manufacturing (AM), commonly known as 3D printing technology, is a rapid prototyping technology that is different from traditional material-reduction manufacturing.

Through digital three-dimensional scanning and layered processing of the model with the help of digital manufacturing equipment similar to printers, materials are continuously superimposed to form the required solid model.

Additive Manufacturing Flowchart :

3D printing technology was first developed by Charles Hull in 1986 in a process called stereolithography (SLA), and later developed technologies such as selective laser sintering (SLS), selective laser melting (SLM), microjet bonding technology (3DP).

Since entering the 21st century, 3D printing technology has made new advances and developments, and many small technologies that meet the needs of specific industries have been born under the subdivision of big technologies.

For example, SLA Technology: digital light processing (DLP), multi-jet technology (Ployjet), SLM Technology: direct metal laser sintering (DMLS).

Currently, it has been widely used in aerospace, medical equipment, construction, automobiles, energy, jewelry design and other fields.

Time magazine listed additive manufacturing as “the 10 fastest growing industries in the United States.”

The UK's The Economist magazine believes that it will “promote the realization of the third industrial revolution together with other modes of digital production”, change future ways of production and life, change the way of manufacturing goods, change the global economic pattern, and then change human life.

Technical analysis of the system of previous industrial revolutions

| Industrial Revolution | Characteristics | Theoretical basis | Energy/Power Unit | Manufacturing Paradigm | Manufacturing Paradigm |

| The first industrial revolution (1750-1850) |

Mechanization | Steam engine | Original manufacturing of equal material and reduced manufacturing of material | Single machine production | |

| The second industrial revolution (1850-1950) |

Electrification | Mechanical reduction theory based on certainty and standardization | Petrochemical energy/internal combustion engine, engine | Modern manufacturing from reduced and equal materials | Assembly line-based mass production |

| The third industrial revolution (1950-2020) |

Digitization | Cybernetics + system theory | Jet power, nuclear power | Modern manufacturing from reduced and equal materials | Computer-based automatic production |

| The fourth industrial revolution (2020-2080?) |

Intellectualization | System + cybernetics + information theory | Renewable energy/power plant based on controlled nuclear fusion | Process integration based on additive manufacturing | Industrial Internet-Based Smart Factory |

Compared with traditional manufacturing technology (reduced material manufacturing), 3D printing does not need to make molds in advance, remove a large amount of materials in the manufacturing process, and obtain the final product without complex forging processes.

It has the characteristics of “removing molds, reducing waste and reducing inventory”.

In production, it can optimize the structure, save materials and energy, and significantly improve manufacturing efficiency.

This technology is applicable to new product development, rapid single-part and small-batch manufacturing, complex-shaped part manufacturing, mold design and manufacturing, etc.

At the same time, it is also applicable to the manufacturing of difficult-to-process materials, shape design inspection, assembly inspection and rapid reverse engineering.

Time of invention of 3D printing technologies and main companies

| SLA | Inventor: Charles Hull (1984) Dominant company: America 3D Systems, Liantai Technology |

| LOM | Inventor: Michael Feygin (1986) Dominant company: America Helisys |

| FDM | Inventor: Scott Crump(1988) Dominant company: America Stratasys/3Dsystems |

| SLS | Inventor: CR Dechard (1989) Dominant company: America 3DSystems, Huashu high tech |

| 3DP | Inventor: Emanual Sachs(1993) Dominant company: America Zcorporation |

| SLM | Inventor: Dieter Schwarze (1995) Dominant company: German SLM Solution, bolite |

| EBM | Inventor: Arcam AB (1997) Dominant company: Sweden Arcam AB |

| Polijet3D | Inventor: Objet(2000) Dominant company: Israel3D systems |

Basic principles of additive manufacturing

The additive manufacturing process mainly includes two processes: three-dimensional design and layer-by-layer printing.

First, computer modeling software is used for modeling, and then the constructed three-dimensional model is partitioned into sections layer by layer to guide the printer in layer-by-layer printing.

1. 3D Design:

The default file format for cooperation between the design software and the printer is the STL file format.

An STL file uses triangular surfaces to approximate the surface of an object.

The smaller the triangular surface, the higher the resolution of the generated surface.

PLY is a scanner that checks three-dimensional files generated by scanning.

VRML or WRL files generated by PLY are often used as input files for color printing.

2. Layer by layer printing:

The printer reads the cross-section information in the document, prints these cross-sections layer by layer with liquid, powder, or sheet-form materials, and then joins the cross-sections of each layer in various ways to create an entity, which You can create articles of any format.

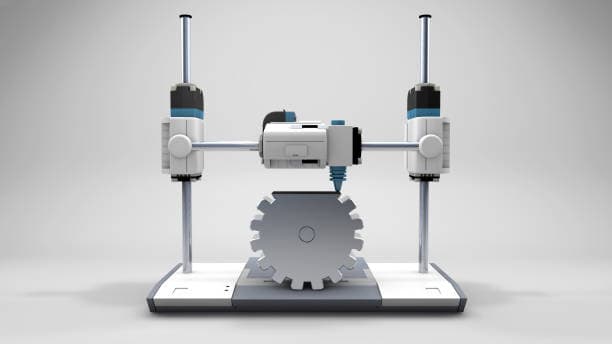

Additive manufacturing machine printing work diagram:

The working principle of the additive manufacturing machine is basically the same as that of a common printer, but the printing materials are very different.

The printing materials of ordinary printers are ink and paper, while the additive manufacturing machine contains different “printing materials” such as metal, ceramics, plastic and sand.

After the printer is connected to the computer, materials can be stacked layer by layer through computer control (the layered processing process is very similar to inkjet printing), and finally the design on the computer can be transformed into a physical object.

Additive manufacturing machine is a type of equipment that can “print” real 3D objects.

Additive technology classification

The ISO/ASTM 52900:2015 standard issued by the additive manufacturing technology committee of the international standardization organization classifies additive technology into seven categories, namely: stereolithography (SLA)

- Adhesive spraying (3DP)

- Directional energy deposition (DED)

- Thin lamination (LOM)

- Material extrusion (FDM)

- Spraying of materials (ployjet)

- Powder bed fusion (SLM, SLS, EBM)

1. Selective laser sintering (SLS)

The principle is that the solid powder is selectively sintered layer by layer by laser (in addition to the main metal powder, a certain proportion of binder powder with a low melting point needs to be added, and the binder powder is generally a metal powder with a low melting point fusion or an organic resin, etc.), and the sintered powder is superimposed on the solidified powder layer to finally form a part with the desired shape.

The main device on which this technology is based is an infrared laser, and the energetic working environment is an argon or nitrogen atmosphere.

It has the advantages of a simple manufacturing process, high production efficiency, many types of molding materials, high material utilization rate, wide use of finished products, and no need to consider support systems.

The disadvantage is that due to the action of the adhesive, the entity has pores, poor mechanical properties and requires remelting and reprocessing at high temperature.

In addition, when the product is stored for a long time, it becomes deformed due to the release of internal stresses, and the surface quality is average. The operation cost is high and the equipment cost is expensive.

2. Selective laser melting (SLM)

The main difference between this technology and SLS technology is that SLM directly heats the metal powder using the laser and does not depend on the binder powder.

The metal powder achieves the metallurgical bonding effect through melting and solidification, and finally obtains the metal parts with the designed structure.

To better fuse metals, SLM technology needs to use laser beams with high metal absorptivity.

Therefore, laser beams with shorter wavelengths, such as the Nd YAG laser (1.064 μm) and fiber laser (1.09 μm), are generally used.

The advantage is that SLM technology uses pure metal powder and the density of the formed metal parts can reach almost 100%;

Mechanical properties such as tensile strength are better than cast ones and even reach the level of forged parts;

The density, mechanical properties and forming accuracy are better than SLS.

Another technology, selective electron beam melting (EBM), is similar to SLM technology, except that EBM uses the kinetic energy of the high-speed electron beam to convert into thermal energy as a heat source for metal fusion, and the work environment is a vacuum.

Using electron beam as a heat source can achieve a higher melting temperature than laser, and the furnace power and heating speed can be adjusted.

It can melt refractory metals and fuse dissimilar metals.

However, there are also disadvantages such as low metal yield, high specific energy consumption and strict vacuum requirements.

3. Directional Energy Deposition (DED)

The operating principle of this technology is similar to that of SLM.

The molten pool is generated in the deposition area by laser or other energy sources and moves at high speed.

The material is sprayed directly into the focus of the high-power laser through the nozzle in the form of a powder or thread.

After melting, it is deposited layer by layer to form the necessary parts.

Compared with SLM technology, this technology has the following advantages:

First, it allows the laser head and part to move more flexibly, thereby increasing design freedom.

Secondly, in the operation of DED equipment, the inert gas flows directly out of the laser head and surrounds the powder flow and molten pool.

It does not depend on the pressure chamber filled with inert gas.

The 3D printing process can begin immediately, greatly reducing production preparation time.

Third, it can produce large parts without any supporting structure.

The downside is that the melting process is not as precise as SLM, and finished parts often need to be reworked.

4. Micro spray bonding technology (3DP)

3DP technology is similar to the SLS process and is made up of ceramic and gypsum powder.

The difference is that the material powder is not bonded by laser sintering solid powder, but by spraying transparent or colored adhesive along the transverse path of the part through the adhesive print head and solidifying the powder.

The powder in the other positions is used as a support, and then a layer of powder is placed.

The process is recycled until printing is complete.

The main device that 3DP technology mainly relies on is the adhesive printhead, which has the advantages of a wide range of molding materials, small power consumption and small equipment volume.

However, the disadvantages are also obvious.

The parts bonded by adhesive have low resistance, require post-treatment and the products are loose and porous.

The polyjet3D technology developed by the company Israel Object is similar to 3DP, but it is not adhesive, but rather a photosensitive polymer molding material that is sprayed.

Nowadays, polyjet3D technology has become the highlight of STRATASYS.

First, a variety of basic materials can be mixed outside the machine, and new materials with better performance can be obtained by combination.

Secondly, the product accuracy can reach a resolution of 16 microns, and smooth and very thin components and models can be obtained.

Finally, the technology is widely used and can be applied to printing parts with different geometries, mechanical properties and colors.

For example, polyjet array technology also supports simultaneous spraying of materials of various designs and colors.

5. Fusion deposition molding (FDM)

Its working principle is to send the filamentary raw materials (generally thermoplastic materials) to the hot melt nozzle through the wire feeder, and then heat and melt them in the nozzle.

Filaments of molten thermoplastic material are extruded through the nozzle and the extrusion head moves precisely along the contour of each section of the part.

The semi-fluid extruded thermoplastic material is deposited and solidified into a precise thin layer of real parts, covering the built parts.

In this way, a solid model or part is stacked layer by layer, from bottom to top.

This technology mainly relies on micro nozzles (generally 0.2 to 0.6 mm in diameter) and heaters (to maintain the temperature of semi-fluid molding materials just 1°C above the melting point).

Its advantages are:

1. No need for expensive components such as lasers, low cost and high speed.

2. There are no restrictions on the usage environment. It can be used in the office or in a home environment.

It is simple to maintain, small in size and pollution-free.

3. The material is easy to change and has high strength and toughness, which greatly shortens the product development cycle, so it can quickly respond to market changes and meet customers' personalized needs.

But there are also defects such as low part precision and difficulty in forming complex components and large parts.

6. Layered Solid Manufacturing (LOM)

This method uses sheets (such as paper or plastic film) as raw material.

According to the cross-section of the part obtained by computer scanning, the sheet coated with hot melt adhesive on the back is cut by laser cutting according to the contour of the part.

After that, the cut sheet is superimposed on the cut sheet, joined by a hot pressing device, and then the cross section of the next layer of the part is cut and glued to form a solid part.

LOM technology mainly depends on the performance of hot melt adhesive, which has the advantages of good model support, easy residue removal, large part size, low cost and high efficiency.

The disadvantage is that the tensile strength and elasticity are low and hollow parts cannot be manufactured;

Subject to the influence of materials, parts printed by LOM technology are easy to absorb moisture and expand, and the surface has staggered lines.

7. 3D light-cured molding (SLA)

The principle of SLA technology is that, under the control of the computer, the surface of the liquid photosensitive resin is scanned point by point by ultraviolet laser according to the sectional data of each layer of the part, so that the thin layer of resin in the scanned The area is cured by a photopolymerization reaction, forming a thin layer of the part, which is cured layer by layer until the entire part is manufactured.

This technology mainly relies on UV laser and suitable photosensitive materials.

On the one hand, the liquid resin material is molded and cured point to line and line to surface, resulting in greater precision and better surface quality.

On the other hand, resin materials themselves have some defects, such as limited strength, rigidity and heat resistance, which are not conducive to long-term storage.

Shrinkage occurs during the resin curing process, which inevitably generates tension or deformation.

Although SLA technology has been developed previously and is relatively mature at present, the costs of SLA equipment are still high, the maintenance and usage costs are high, and the supporting structure of the part needs to be designed.

Wrap it up

According to the above summary of common 3D printing methods on the market, different additive manufacturing technologies generally have differences in materials, energy sources and molding methods.

The choice of additive manufacturing technology depends on the use of parts in downstream industries.

Metallic additive manufacturing technology is generally used in the aerospace field, while non-metallic additive manufacturing technology is more widely used, mainly used in other areas of industrial process design, such as automotive household appliances, medical devices, cultural and creative goods, etc. .

Additive Manufacturing vs Subtractive Manufacturing

Comparison between reducing material manufacturing and increasing material manufacturing

Difference Between Traditional Manufacturing Process and 3D Printing

| Contrast | Traditional manufacturing process | 3D printing |

| Processing principle | Secure the raw material to the equipment and use tools to reduce or remove the raw material from the formation. For example: iron turning and cutting. Or design molds and casting materials. | Scan the printed template, cut the template, and stack materials layer by layer. For example, the options are laser sintering and selective laser melting. |

| Material | The cutting process generates a lot of waste, the value of incomplete surplus materials is damaged, and the material utilization rate is low. | Add materials layer by layer according to the model slice shape. Consumables on demand, saving materials. |

| Mold | Mold design takes a long time and there is a risk of mold failure and time-consuming redesign | No need for traditional tools, fixtures, machine tools or any mold and support structure, saving time |

| Part structure | The traditional integral manufacturing process adopts screw connection and riveting. The splicing structure has many joints, many complex parts and assemblies. | The overall structure is directly assembled, reducing the number of parts, reducing the weight of the structure, fewer joints and good sealing. Assembly is simple and production efficiency is improved. |

| Part performance | Parts are easy to deform and bend after being removed from the tool. | Direct molding, without bending deformation of the parts |

| Product design | Manufacturing guidance design, product design according to the feasibility of process cutting and model making. | Design-driven manufacturing enables bold surface and cavity designs without considering the difficulty of the cutting and model creation process |

| Parts repair | Remeasure the mounting dimension, manufacture new parts and replace them | Add materials to damaged parts for repair |

In the 1980s, additive manufacturing technology began to grow explosively in Europe and the United States.

The application of 3D printing technology dates back to three-dimensional photopolymerization (SLA) technology developed by Charles Hull of the United States in 1986.

Over the next 20 years, a series of 3D printing technology patents such as layered solid manufacturing (LOM) and fused deposition molding (FDM) were released one after another.

Meanwhile, a number of innovative 3D printing companies such as 3D systems, STRATASYS, SLM solutions have gradually formed in Europe and America.

As 3D printing technology started early in Europe and the United States, after more than 30 years of development, SLA (stereoscopic polymerization), SLS (selective laser sintering) and other technologies are relatively mature.

It is relatively perfect in R&D and manufacturing of high-temperature metal materials and equipment.

Since the 21st century, additive manufacturing technology has been developed in several subfields, such as digital light processing (DLP) and multiple jet technology (Ployjet).

Special 3D printing materials and 3D printing equipment have also emerged.

At present, the 3D printing industry around the world has basically formed a complete industrial chain covering raw materials, parts, processes, equipment and services.

Some major companies have upgraded from a single equipment manufacturer to a provider of comprehensive solutions from design to final parts manufacturing.

Development of additive manufacturing technology

In 1986, Charles Hull, an American scientist, developed the first commercial 3D printing machine.

In 1993, MIT was granted a patent for 3D printing technology.

In 1995, Zcorp obtained the sole authorization from MIT and began developing additive manufacturing machines.

In 2005, Spectrum Z510, the first high-definition color additive manufacturing machine on the market, was successfully developed by zcorp.

In 2010, the American Jim Kor team created the world's first city car printed by an additive manufacturing machine.

In 2011, British researchers developed the world's first 3D chocolate printer.

In 2011, engineers at the University of Southampton developed the world's first aircraft made from additive materials.

In 2012, Scottish scientists used human cells to print artificial liver tissue for the first time, using an additive manufacturing machine.

In 2013, Solid Concepts, an additive manufacturing company in Austin, Texas, designed and manufactured a metal additive manufacturing gun.

In 2018, Russian astronauts used the international space station's 3D biological printer to attempt to print the thyroid glands of experimental mice under zero gravity.

In 2019, the University of California, San Diego, for the first time used rapid additive manufacturing technology to manufacture a scaffold for the spinal cord that mimics the structure of the central nervous system.

After loading neural stem cells, it was implanted into the spines of rats with severe spinal cord damage, successfully helping the rats regain their motor function.

3D printing technology and field of application

Additive manufacturing of metallic materials

- Application of selective laser melting (SLM):

Small complex precision metal parts, metal crowns, medical implants.

- Laser Near Network Formation (LENS) Applications:

Large complex metallic aircraft components

- Application of Electron Beam Selective Melting (EBSM):

Aerospace complex metal components; medical implants;

- Electron beam fuse deposition (EBDM) application:

Large aerospace metal components

Related Reading: 3D Laser Printing: Additive Manufacturing Process and Applicable Materials

Additive manufacturing of non-metallic materials

- Application of forming photopolymerization (SLA):

Design and development of industrial products, production of innovative and creative products, wax molds for precision casting.

- Fused deposition forming (FDM) applications:

Design and development of industrial products and production of innovative and creative products.

- Application of selective laser sintering (SLS):

Engineering plastic parts for the aerospace sector, sand cores for automobile and household appliance castings, medical-surgical guides and orthopedic implants

- Three-dimensional printing (3DP) application:

Design and development of industrial products, sand cores for foundry, medical implants, medical models, innovative and creative products, architecture.

- Application of material spray forming (Ployjet):

Design and development of industrial products, medical implants, production of innovative and creative products, wax molds for casting.

Type of 3D printing material

3D printing materials are an important material basis for the development of 3D printing technology, and materials are an important constraint for the development of 3D printing.

According to 3D printing downstream application industry statistics released by wohlerAssociates Inc. in 2019, the automobile industry accounted for the largest proportion, 16.4%;

Consumer electronics and aerospace take second and third place with 15.4% and 14.7%.

According to the characteristics of products in the downstream area, there is a great demand for metal and composite materials, which is expected to become the “turning point” of 3D printing materials.

3D printing materials and fields of application

The raw materials used in 3D printing in general are developed especially for 3D printing equipment and processes, which are different from common metal materials, plastics, plaster, resins, etc.

Additive manufacturing technology can be classified from the perspective of material properties:

For example, liquid photosensitive resin material is used for stereolithography (SLA);

Layered solid manufacturing (LOM) requires sheet materials such as paper and plastic film, while selective laser sintering (SLS) and selective laser melting (SLM) are mainly metallic and ceramic powder materials.

3D printing materials and corresponding technologies

| Impression material | 3D printing and modeling technology |

| Thermoplastic Paper, metallic film, plastic film Plaster, ceramic powder Liquid photosensitive resin Metal, alloy, thermoplastic, ceramic powders |

FDM LOM 3DP SLA\DLP\Ploy Jet SLS\DMLS\SLM\EBM |

1. Metal materials

Heavy industrial products often rely on metal materials that are resistant to high temperatures and corrosion.

To meet the needs of heavy industrial products, 3D printing was developed first and invested more in metal powder.

Metal powder generally requires high purity, good sphericity, narrow particle size distribution and low oxygen content.

At present, the metal powder materials used for 3D printing mainly include titanium alloy, cobalt-chromium alloy, stainless steel and aluminum alloy materials, as well as gold, silver and other precious metal powder materials used. for jewelry printing.

Titanium alloy is widely used in cold-end compressor parts of aircraft engines and various structural parts of rockets, missiles and aircraft because of its high strength, good corrosion resistance and high heat resistance.

Furthermore, stainless steel powder is widely used for its corrosion resistance. 3D printed stainless steel models have high strength and are suitable for printing large-scale items.

At present, Europe and the United States have carried out direct laser forming of small-sized stainless steel, superalloys and other parts.

In the future, rapid laser forming of large-scale metal components made of superalloy and titanium alloy will be the main technical direction.

2. Engineering plastics

Engineering plastics refer to industrial plastics used as industrial parts or coating materials, which are excellent in strength, impact resistance, heat resistance, hardness and aging resistance.

Engineering plastics are currently the most widely used 3D printing materials, including ABS materials, PC materials, nylon materials, etc.

PC-ABS is one of the most widely used thermoplastic engineering plastics.

It has the toughness of ABS and the high strength and heat resistance of PC materials, and is mainly used in the automobile, home appliance and communication industries.

The resistance of the sample made with this material is around 60% higher than that of traditional parts.

In industry, PC-ABS materials are typically used to print thermoplastic parts such as conceptual models, functional prototypes, manufacturing tools, and final parts.

PC-ISO is a white thermoplastic material that has passed medical and health certification.

It has high strength and is widely used in the pharmaceutical and medical device industries such as surgical simulation, skull repair, dentistry and other professional fields.

3. Photosensitive resin material

Photosensitive resin is generally liquid, which can immediately cause the polymerization reaction to complete curing under a certain wavelength of ultraviolet light, and can be used to make high-strength, high-temperature resistant and waterproof materials.

Somos 19120 material is pink, which is a special casting material.

After molding, it can directly replace the precision casting wax film prototype, avoid the risk of mold development, and have the characteristics of low ash retention rate and high precision.

The next Somos material is a white material. It is a new type of PC material with very good strength. Basically, it can meet the performance of nylon material made by selective laser sintering (SLS) and has better precision and surface quality.

Components made of this material have the best rigidity and strength so far, while maintaining the advantages of light-cured three-dimensional modeling materials such as exquisite workmanship, precise size and beautiful appearance.

It is mainly used in the fields of automobiles, household appliances and electronic consumer goods.

4. Ceramic materials

It has high strength, high hardness, high temperature resistance, low density, good chemical stability, corrosion resistance and other excellent characteristics, and is widely used in aerospace, automobile, biology and other industries.

In traditional technology, complex ceramic parts need to be formed by molds, which have high processing costs and long development cycles, and are difficult to meet the needs of continuous product upgrades.

In 3D printing, selective laser sintering (SLS) is used to process ceramic powder, which can eliminate complicated design steps and realize rapid product prototyping.

This material has certain defects. SLS uses a mixture of laser sintered ceramic powder and a certain binder powder.

After laser sintering, ceramic products need to be placed in a temperature-controlled oven for post-treatment.

Furthermore, the surface tension of the liquid phase is high when the ceramic powder is directly and quickly sintered by laser, and large thermal tension will be generated during the rapid solidification process, thus forming more microcracks.

5. Other materials

In recent years, food materials such as colored plaster, artificial bone powder, cellular biological materials and sugar have also been applied in the field of 3D printing.

Color plaster material is a colorful 3D printing material.

Based on the formation principle of layer-by-layer printing on powder media, after processing 3D printed products, fine particle effects may appear on the surface, which look like stones, and fine ring-like textures may appear on the surface curve.

Therefore, they are mainly used in puppetry animation and other fields.

The fresh meat printed by the University of Pennsylvania in the United States is made using laboratory-grown cellular media to generate a fresh meat-like substitute substance, using water-based sol as a binder and then combining it with special sugar molecules. .

There is also biological ink made from human cells, which is still in the conceptual phase, and the same special biological paper.

When printing, biological ink is sprayed onto biological paper under the control of the computer and eventually forms various organs.

In terms of food materials, at present, 3D sugar printers can directly make beautiful and delicious various-shaped desserts by spraying heated sugar.

Existing special materials for additive manufacturing include metallic materials, non-metallic inorganic materials, organic polymeric materials, and biomaterials.

However, the application of additive manufacturing technology is seriously restricted by the small number of unique materials and insufficient performance.

At present, industry leaders and some materials companies have defined the field of special materials one after another, breaking through a series of new polymer composite materials, high-performance alloy materials, bioactive materials, ceramic materials and other special materials.

Relevant companies combine nanomaterials, carbon fiber materials and other materials with existing material systems and develop multifunctional nanocomposites, fiber-reinforced composites, inorganic filler composites, metal filler composites, polymer alloys and other composites, which not only endow the materials of multifunctional characteristics, but also expand the field of application of additive manufacturing technology, making composites one of the trends in the development of special materials.

Advantages of additive manufacturing

Compared with the traditional material reduction manufacturing method (material removal machining method by cutting tools), additive manufacturing (additive manufacturing) has many advantages:

1. Reduce manufacturing time and improve efficiency:

It usually takes several days to make a model by traditional methods, depending on the size and complexity of the model, while the time can be reduced to several hours by three-dimensional printing technology, which obviously depends on the performance of the printer and the size and complexity of model.

2. Improve raw material utilization efficiency:

Compared with traditional metal manufacturing technology, additive manufacturing machine produces fewer by-products in metal manufacturing.

With the progress of printing materials, “liquid format” manufacturing may become a more environmentally friendly processing method.

3. Complete the realization of complex structures to improve product performance:

Traditional reduced material manufacturing has limitations in processing complex shapes and internal abdominal structures, while additive manufacturing can improve product performance when manufacturing complex structures and has unparalleled advantages in aerospace, mold processing and other fields.

3D printing event

1984-1989

1984: Charles Hull developed the first SLA 3D printing technology

1986: LOM technology was formed and 3D systems were established

1988: FDM technology formed

1989: formation of SLS technology, establishment of STRATASYS and EOS

1990-2010

1992: 3DP technology was formed and 3D Systems manufactured the first light-cured three-dimensional molding machine.

2002: 3D printing of the first human organ – the kidney.

2006: the first SLS printer was born

2009: 3D printer kit produced by makerbot entered the market

Since 2011

2011: materialize company offers gold and silver jewelry printing service for the first time

2012: 3D printing giants Stratasys and Objet merged

2013: China's first 3D printed large-scale aircraft titanium alloy main bearing components

2016: GE acquired two 3D printing giants, Concept Laser and Arcam.