This is a summary of luminaire design in the industry, but it's not as simple as it seems. Through our research and discussions with various experts, we discovered that preliminary design often faces positioning and fixing issues that are not adequately addressed.

Without adequate solutions to these challenges, any innovative design will be of no practical value. To ensure the success and integrity of fixture design and processing, it is crucial to have a solid understanding of the basic principles of positioning and fastening.

Locator knowledge

1. Basic principles of lateral positioning of the workpiece

“When positioning the part, such as the support, the most basic principle to follow is the three-point principle. This principle, also known as the support principle, derives from the concept that “three points that are not on the same line determine a plane”.

With three points, a face can be determined, leading to the determination of a total of four faces. However, it can be challenging to locate the fourth point on the same plane, regardless of the method used.”

Three principles

For example, when using four fixed-height locators, only three of them may contact the workpiece, leaving a high probability that the fourth will not. To resolve this issue, it is commonly recommended to configure the locator based on three points, with the distances between these points kept as wide as possible.

Additionally, when configuring the positioner, it is important to determine the direction in which the processing load will be applied. This direction refers to the direction in which the handle of the tool or tool will travel. Neglecting this consideration can have a significant impact on the overall accuracy of the workpiece.

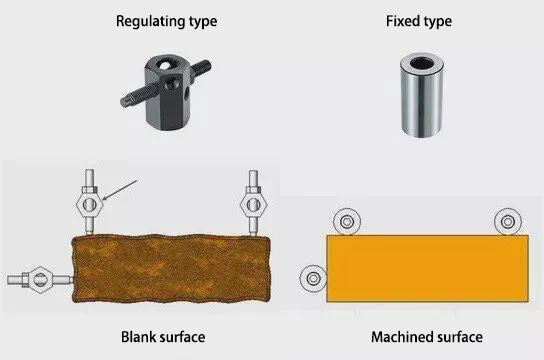

When positioning the raw surface of the workpiece, an adjustable screw-type positioner is typically used. To position the processing surface, a fixed positioner is used (where the contact surface of the part is ground).

2. Basic principles of positioning from the part hole

When positioning the part, it is essential to use a pin with a tolerance that fits the holes processed in the previous step.

To achieve the desired positioning accuracy, the pin must have the same accuracy as the part hole and match the specified tolerance.

In addition, straight pins and diamond pins are commonly used for positioning, making it easier to assemble and disassemble the workpiece and reduce the likelihood of the workpiece and pin getting stuck.

Use pin placement

Of course, it is possible to use straight pins for both positions by adjusting the fitting tolerance. However, for more accurate positioning, it is typically more effective to use a combination of a straight pin and a diamond pin.

When using both types of pins, the connecting line of the diamond pin, at the point of contact with the workpiece, is normally perpendicular to the connecting line of the straight pin, forming a 90-degree angle. This setup method is used for angular positioning, specifically to determine the direction of rotation of the part.

Relevant clamp knowledge

1. Classification of forceps

According to the fixing direction, it is generally divided into the following categories:

Next, let's take a look at the characteristics of various clamps.

1. Clamp pressed from above

The clamping device that compresses from the top of the part is the most stable and causes the least deformation during the clamping process. As a result, the first consideration in part processing is clamping from the top. The most commonly used accessory for this type of fastening is a manual mechanical accessory.

For example, the “pine leaf” clamp is a commonly used type of clamping device. It consists of a pressure plate, stud, jack and nut.

Furthermore, according to the shape of the workpiece, different shapes of pressing plates can be selected to match the different shapes of the workpieces.

The relationship between the torque and clamping force of the pine veneer clamp can be calculated by the propelling force of the screw.

The simple calculation formula for clamping force is as follows:

F(kN) = T(N·m)/0.2d

(d refers to the nominal screw diameter)

In addition to the pine needle clamp, there are also the following similar clamps for clamping above the workpiece.

2. Side fixation

The original method of clamping the part from above is the most stable and accurate and also results in the lowest processing load on the part.

However, when fixing from above is not feasible due to factors such as machining above the part or inadequacy, it may be necessary to clamp the part from the side.

It should be noted, however, that clamping the workpiece laterally can result in an upward force. Careful consideration should be given to eliminating this force when designing the fixture.

In addition to the clamps shown in the figure above, side clamps are also available.

These side clamps generate an oblique downward force when thrust is produced, effectively preventing the workpiece from floating.

There are also other similar clamps for lateral fixation.

3. Clamp for clamping the pull-down workpiece

When processing the upper surface of a thin sheet metal part, it is not possible to clamp it from above and compressing it from the side is not practical. The most viable clamping method is to clamp the workpiece from below.

If the workpiece is made of iron, a magnetic clamp can usually be used to clamp it from below. For non-ferrous metal parts, vacuum suction cups can usually be used to secure them.

The clamping force is directly proportional to the contact area between the workpiece and the magnetic gripper or vacuum suction cup.

However, if the processing load is too high when processing small parts, the results may not be ideal.

In addition, when using a magnet or vacuum chuck, the contact surface with the magnet and vacuum chuck needs to be smooth to be safe and normal.

4. Clamp fixed with hole

When carrying out multi-faceted simultaneous processing or mold processing on a 5-axis machine, it is advisable to use hole clamping to prevent the fixture and tools from affecting the result. This method is superior to top and side clamping as it applies less pressure to the workpiece, reducing the likelihood of warping.

Direct machining with holes

Set the pull pin for fastening

2. Pre-fixation

The main focus is on fixing the part clamp. Improving operability and utilizing pre-attachment is also crucial.

When the workpiece is placed vertically on the base, gravity will cause it to fall downwards.

To avoid this, you need to manually hold and clamp the workpiece while using the clamp to operate.

Pre fixation

If the workpiece is heavy or if multiple parts are clamped simultaneously, operability will be significantly reduced and the clamping process will take a long time. In such situations, the use of a spring-loaded pre-clamping product can help keep the part in a stable state during clamp operation, significantly improving operability and reducing clamping time.

3. Precautions when selecting tweezers

When multiple types of clamps are used in the same tooling configuration, it is crucial to standardize the tools used to tighten and loosen them. This helps minimize operator workload and decrease total workpiece clamping time.

For example, as shown in the figure on the left, using different types of wrenches for fastening operations can lead to increased workload for the operator and longer fastening times.

On the other hand, as illustrated in the figure on the right, when tools and wrenches are standardized and screw sizes are unified, the operation becomes much more convenient and efficient for on-site personnel.

Workpiece clamping operability

Additionally, when setting up the clamp, it is crucial to prioritize ease of clamping the workpiece. If the workpiece needs to be clamped at an angle, its handling can become complicated. This issue must be taken into consideration when designing clamping tools to avoid inconvenience.