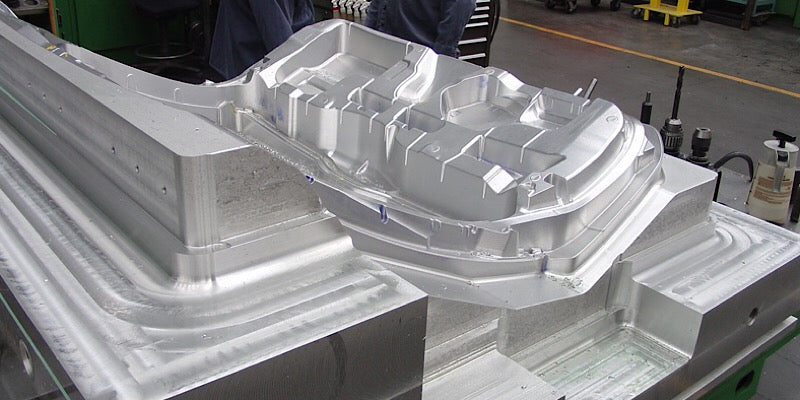

As your creative production supplier, we are committed to producing cost-effective plastic injection molds and molds for each customer. Furthermore, we continually improve our aluminum mold processes to provide you with a high-quality experience.

About 80% of all plastic parts are manufactured by plastic injection molding. For a long time, injection molding was considered purely a mass production process. With the innovation of industrial techniques, rapid injection molding is no longer the only way to develop molds. CNC machining centers have significantly reduced mold processing time. CAD/CAM/CAE systems have reduced design and inspection times. Additionally, new format variants have been developed. Aluminum injection molds and 3D printed molds compete with hardened steel molds in the manufacturing market. But what is the difference between them? Which format can make your product more efficient?

Of course, you want your prototype to be produced as quickly, cheaply, and looking as well as possible. Let's compare aluminum, steel and 3D printed injection molds and find out which is most useful in each situation.

1. Processing time

Lead time is the amount of time between the start of mold development and the time when parts can be produced. The design methods and calculations for the three types of molds are different in practice, but the main differences occur at the manufacturing stage.

Aluminum injection molds are made from aluminum blanks through CNC machining and finishing. In some cases, additional electrical discharge machining (EDM) is necessary when cavities must have sharp corners that cannot be achieved by milling. In general, the processing is mainly mechanical, no thermal processing is required, and almost no special tools are required. An average aluminum cavity is made in 10 to 15 days.

Steel molds are made in a similar way, but have some differences. Firstly, the material is much harder and takes much longer to process, wears out cutting tools and requires special tools. Secondly, multiple thermal processing operations are required to extend the mold life. All of this takes time. Therefore, steel injection molds take 2 to 5 months to complete.

3D printed shapes are created using metal sintering additive manufacturing techniques. Very fine metal powder is sintered layer by layer to form the cavity of an injection mold. The main advantage of this process is that it requires practically no manufacturing preparation and no tools. The average time to create this form is just 2 to 3 days.

2. Robustness

Robustness is essentially the number of parts a mold can produce before becoming too worn out. An important parameter to consider when making a batch of products.

Steel injection molds are hardened through heat treatment and are specifically designed to last. They have a minimum of joints and are made of the most durable steel. That's why they last millions of pieces.

Aluminum tools are made from a softer material, but some aluminum alloys have excellent strength. This means the molds can hold up to 5,000 parts per batch. The average is 100 to 2,000 pieces.

3D printed shapes are the worst when it comes to sturdiness. The sintered cavity has many problems. It is porous and not as stable as those made from solid pieces. Currently, the 3D printed cavity can contain 50 to 200 parts per batch.

3. Manufacturing time

When a product must be manufactured in batches, manufacturing time per piece is an important factor. By manufacturing time I mean the time between injecting the liquid polymer and ejecting the final part. This factor varies depending on the mold material, injection pressure and temperature.

Steel molds can withstand the highest injection pressures and temperatures, which is why the manufacturing process can take 5 to 10 seconds.

Aluminum injection molds are not as stable, so their pressure and temperature are 20-30% lower than steel molds. Manufacturing time is 44 to 70 seconds, which is significant when we are talking about thousands of parts.

3D printed shapes perform even worse under high temperatures and pressure. Therefore, they take longer to produce a part, 150-250 seconds.

4.Part accuracy and surface quality

The quality of the part is one of the most important factors. Ultimately, this piece serves as an element of a larger mechanism and can be presented to future investors. The piece must look professional

The accuracy of steel and aluminum injection molds is similar and depends only on machining and polishing ability. However, the accuracy of 3D printed shapes is determined by additive manufacturing processes. In additive manufacturing, the material is melted and cooled, and thermal deformation significantly reduces accuracy. Modern technologies can produce steel and aluminum cavities with tolerances of up to IT6 and 3D printed shapes with tolerances of up to IT9.

5.Flexibility

Flexibility is important for pre-production prototypes when you're just testing how the final product looks and functions. After you make the first prototype with some materials, you want to test the materials you originally chose for the product and test the manufacturing program. In most cases, you will encounter problems that force you to change your design. For example, an error was found during functional testing or the spraying process resulted in a porous part. In this case you want to change the design and therefore the shape. Different mold materials have different flexibility.

Steel molds are hardened by heat treatment. This usually happens after all the essential parts have been machined and only a thin layer of material remains to be sanded. If you need to change some characteristics, it may be difficult because the hardness of the cavity is very high.

Aluminum molds are made from a softer material and their cavity is usually made as a separate piece embedded in the mold base. Therefore, it is much easier to remove the cavity and make adjustments.

3D printed molds are difficult to modify because part of the cavity needs to be machined and the surface finish is not uniform, as machining provides a better surface finish. It is easier to make the mold from scratch, which does not take much time, but incurs undesirable additional costs in prototyping and batch testing before production.