What is a slot machine?

Slotting machines are a type of equipment used to cut metal plates.

There are two types of slotters: angle adjustable and non-adjustable.

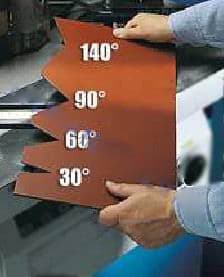

The adjustable angle range is between 40° and 135°, and the angle can be adjusted to the desired position within this range.

The main structure of the carver is made of strong and durable steel plate.

The standard machine comes equipped with all necessary tools to meet the processing needs of most sheet metal processing plants.

There is no need to create a separate set of dies, as is common with punch presses, to process parts with a specific angle or thickness.

Angle notching machine has several advantages over punching machines, including:

- Lower cost of use

- Reduced hassle of frequent die changes and fixing with regular punches

- Greater work efficiency

- Decreased work intensity for workers

- Reduced risk for workers

- Quiet processing creates a peaceful working environment for the factory and employees

This slotting machine is ideal for cutting metal plates and is widely used in various industries such as automobile manufacturing, shipbuilding, elevators, electrical equipment, pipes, kitchen appliances and stainless steel products.

Types of slot machine

Slotting machines can be classified into three categories: pedal-operated, pneumatic and hydraulic.

Furthermore, slotting machines can be divided based on the angle of the blades at both ends into adjustable-angle machines and fixed-angle machines.

Hydraulic adjustable angle notchers feature a wide range of cutting angles and remarkable cutting precision. With a cutting angle range typically from 40 to 135 degrees, these machines offer versatility and precision in the cutting process. The angle can be adjusted within this range to obtain optimal cutting results, making it suitable for cutting various materials with different thicknesses. The machine can be adjusted for symmetrical or asymmetrical processing. Furthermore, the cut edge of the plate has a smooth finish.

On the other hand, fixed angle hydraulic notchers have a shear angle of 90 degrees, which provides high cutting speed, compact structure and small volume. These machines are also known for their ease of operation.

Pedal slot machine:

The pedal operating mode, as the name suggests, is operated via the pedal, which not only reduces the work involved but also significantly increases work efficiency. Pedal carver scissors are made of silicone, which provides durability and resists damage and blade collapse.

Pneumatic slotting machine:

This machine mainly uses pneumatic transmission and is designed for cutting square metal boxes and metal disc box corners. The machine is characterized by its relatively lightweight design, attractive, modern appearance and reliable cutting quality.

Hydraulic slotting machine :

This cutting machine is equipped with hydraulic transmission and is a cutting-edge technology designed to quickly and accurately cut triangular notches on the edges and corners of metal plates. It has broad strength and resilience, making it a versatile tool for various hardware processing industries. This type of chamfering machine is widely used and highly sought after in the current market.

Double Station Hydraulic Notching Machine

The double station hydraulic chamfering machine is an upgrade of the original angle cutting machine. By using a specialized die, this machine is capable of punching, grooving, bending and corner cutting, which expands its range of applications.

Features of the slot machine

Slotting machines mainly include two types: fixed-angle slotting machines and adjustable-angle slotting machines. The following are its performance characteristics:

- The machine has a compact structure and mechanically robust design, ensuring rigidity and stability. The solid guide increases cutting precision and extends blade life.

- Easy operation is facilitated via foot control, and the operator can choose between jog or cycle modes.

- The angle scale is easily adjustable using the handwheel, making angle adjustments convenient.

- The stroke can be adjusted to optimize cutting speed.

- Equipped with a shear length ruler, the position of the positioning stop can be adjusted to set the desired shear length.

- The surface of the work table is ground to ensure that it is smooth and flat without causing damage to the workpiece.

- The cutter is suitable for cutting carbon steel and stainless steel.

- A presser foot is included to eliminate distortion and deformation of the sheet during cutting.

- A plastic protective cover helps prevent contact with the cutting part and ensures the safety of operators and equipment.

- The guide post is automatically lubricated, reducing maintenance requirements.

Features of Adjustable Angle Hydraulic Slotting Machine

- The machine features a lower hydraulic transmission design.

- The shear angle is adjustable.

- The shear angle adjustment mechanism is a combination of mechanical, electrical and hydraulic interlocking.

- The machine is equipped with an automatic blade gap adjustment device, allowing adjustments according to the thickness of the material to be sheared.

- The operator can select between single-stage and step-by-step operation modes.

- The scaling device has the ability to adjust to variable angular positions.

- The machine has a centralized lubrication system.

Features of Fixed Angle Slotting Machine

- Blade clearance is automatically adjusted based on the thickness of the material being cut.

- The machine uses a hydraulic transmission mode.

- The fixed shear angle is set at 90 degrees.

- The machine has an adjustable angle scale device.

- The entire machine is constructed using an overall welding frame made of steel sheets.

- The machine has a centralized lubrication system.

Operating Procedures for Angle Notching Machine

1. Basic operation steps

1.1 S Pie:

① Set the main power switch to the “on” position.

② Turn the emergency stop button clockwise to open it.

③ Press the oil pump start button.

④ Use the selector switch to choose between inching and single-time modes.

⑤ Adjust the ruler to the desired shear angle size, lock it in place and position the workpiece.

⑥ Press the foot shear switch to start the cutting process.

1.2 Commissioning:

Before angle cutting, it is important to carry out a test. To do this:

- Select single time mode on selector switch.

- Step on the foot shear switch to watch the white steel knife move. If the movement is not normal, it may cause damage to the knife and the machine.

- Once the knife movement is confirmed to be normal, perform 1-2 continuous cuts to ensure there are no abnormal sounds before starting the actual work.

1.3G ear confirmation and adjustment:

Before cutting at an angle, make sure the gear is adjusted to the specified position.

1.4 Angular cutting

1.4.1 Before cutting at an angle, remove any burrs on the edge of the plate.

1.4.2 Angular cutting must be carried out close to the gear surface.

1.4.3 After angle cutting is completed, any waste material will fall into the waste material box located behind the machine body. It is important to clean the box regularly.

1.5S hut

To turn off the machine, follow these steps:

- Step on the pedal.

- Press the emergency stop button.

- Turn the main power supply to the “off” position.

2. Safety operational procedures

2.1 Strictly comply with safety operation regulations and use necessary personal protective equipment.

2.2 Keep the workbench clear of all tools and other materials and maintain sufficient free space in the work area.

2.3 During operation, never place your hands near the cutting edge and avoid touching the pedal while looking at the line or handling the workpiece to avoid accidents.

2.4 If any failure occurs during operation, immediately press the emergency stop device. After the machine stops, turn off the power for maintenance, which must be carried out by professional personnel.

2.5 After turning off the machine, do not press the switch or adjust the path randomly to avoid damage to the buttons and molds.

2.6 Only authorized personnel are authorized to start or operate the machine tool. No unauthorized personnel are allowed to do so without permission.

Slot machine maintenance

3.1 Before starting the machine, remove any foreign material and metal debris from the angle cutting machine, and check the electrical switches, cables and fasteners to ensure they are normal and secure. Before performing maintenance or cleaning, lower the tool mold and turn off the machine.

3.2 Hydraulic Oil Circuit

3.2.1 Check the oil level in the oil tank weekly and also check if the hydraulic system is undergoing repairs. Under normal operating conditions, the oil level should be maintained at 2/3 of the dipstick and not fall below the red line.

3.2.2 The machine uses No. 46 anti-wear hydraulic oil.

3.2.3 The newly acquired carver must have its hydraulic oil replaced after one year of use and, thereafter, every two years. To replace the hydraulic oil, clean the oil tank, replace the filter element, and use a special oil filter truck to inject new hydraulic oil into the tank. After filling the oil, the machine can be put into normal use after being turned on and idle for 8 hours.

3.3 Filter

3.3.1 Replace or thoroughly clean the filter during each oil change.

3.3.2 If the machine tool gives an alarm or shows signs of dirty oil, replace the filter.

3.3.3 Inspect and clean the oil tank air filter every 3 months and replace it once a year if possible.

3.4 Lubricate moving parts weekly and use clean lubricating oil.

3.5 After operation, clean the upper knife, lower mold, machine body and surrounding area.

Emergency disposal

If a problem occurs during equipment operation, immediately turn off the machine and turn off the power for inspection. Resume operation only after the problem is resolved.

If the operator is unable to deal with equipment failure, he or she must immediately report the problem to equipment management personnel.

In case of injury, remain calm and avoid panicking. If possible, take measures to ensure your safety and that of others and notify relevant personnel to carry out emergency rescue of the injured.

After emergency treatment has been provided, immediately inform the workshop safety management personnel. Workshop safety management personnel will then go to the site for follow-up treatment.

The extent of the injury will dictate the appropriate course of treatment. If on-site rescue is not possible, call emergency medical assistance immediately and report the situation to the leader.