There are several types of connections, which can be divided into two categories based on whether they are removable after connection: removable connections and non-removable connections.

This chapter mainly discusses non-removable connections, including TOX riveting, welding, punching and riveting, and nail riveting.

Section 1: TOX Riveting

1. Definition:

Using a simple convex mold, the connecting part is pressed into the concave mold. Under additional pressure, the material inside the concave mold flows outwards, resulting in a smooth, burr-free circular connection point.

This will not affect its corrosion resistance, even for sheet materials with painted coatings or layers. This is because coatings and paint layers also deform and flow along with the material.

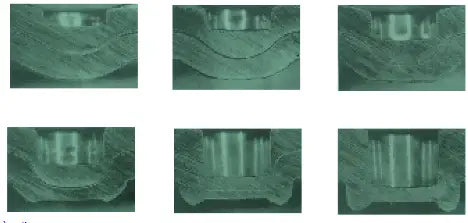

The material is compressed on both sides and the plate on the concave side of the mold, forming a TOX connection point, as shown in the diagram below:

2. Connection method:

TOX riveting can be used to connect two or more layers of boards with the same or different materials and thicknesses.

Under the same conditions, the static connection resistance of a single point TOX is 50% to 70% of that of spot welding, and the resistance of double points is the same as that of spot welding.

3. Connection range of different rivet points: (unit mm)

| Rivet diameter | 12 | 10 | 8 | 6 | 5 | 4 | 3 |

| Thickness range of material for connection | 4~11 | 1.75~7 | 1.6~6.0 | 1.0~3.0 | 0.9~2.5 | 0.6~2.0 | 0.5~1.5 |

| Minimum distance from edge to center of TOX rivet | 10 | 8 | 7 | 6 | 6 | 5 | 4 |

Note: The diameter of the TOX rivet is closely related to the connection strength. The larger the diameter, the stronger the connection.

4. Defects of TOX riveting:

(1) Depends on positioning fixtures or mold blocks for positioning.

(2) The minimum width of the connected material is affected by the diameter of the TOX mold.

5. Advantages of TOX mold:

In addition to being used in specialized equipment, it is also suitable for common punching machines, so its riveting range is much greater than that required by TOX.

For board materials with painted coatings or layers, the protective layer at the connection point is not damaged and the original anti-corrosion properties are maintained.

6. Schematic diagram of TOX rivet formation:

Section 2: Welding

1. Definition

The essence of the welding process is to use appropriate physical and chemical processes to bring metal atoms closer to two surfaces separated by lattice distance (0.3-0.5 nm), forming a metallic bond, so that the two metals are connected into one and achieve the purpose of welding.

2. Welding Methods and Classification

In the manufacturing process, tungsten inert gas arc welding (TIG), metal inert gas arc welding (MIG) and spot welding are the most common welding methods. The following is a brief introduction of these three welding methods:

A. Tungsten inert gas arc welding

TIG welding is a welding process in which the electrode and arc zone, as well as the molten metal, are all protected by argon gas, isolating them from the air.

The electrode is made of tungsten or tungsten alloy rod and does not melt during the arc burning process, resulting in a stable welding process.

When helium gas is used as a shielding gas, it is called helium arc welding.

TIG welding is widely used in industries such as aircraft manufacturing, atomic energy, chemical engineering and textiles.

It is suitable for welding easily oxidized non-ferrous metals and their alloys, stainless steel, high-temperature alloys, titanium and titanium alloys, and difficult-to-melt reactive metals such as molybdenum, niobium and zirconium.

However, the current carrying capacity of tungsten electrodes is limited and the arc power is restricted, resulting in shallow welding depth, low welding speed, and only suitable for welding parts with a thickness of less than 6mm.

B. Metal inert gas arc welding

MIG welding, also known as gas metal arc welding (GMAW), uses a welding wire as an electrode, and the electrode and arc zone are protected by an inert gas such as argon.

If Ar-O2, Ar-CO2 or Ar-CO2-O2 is used as shielding gas, this is called Metal Active Gas (MAG) welding.

MIG welding can weld almost all metals and is especially suitable for welding aluminum and its alloys, copper and its alloys, stainless steel, etc.

As a welding wire is used as the electrode, a high density current can be used, resulting in a large molten depth and fast filling speed.

It is suitable for welding thick aluminum and copper plates, and the welding deformation is smaller than TIG welding.

MIG welding can also use DC reverse connection and has good sputtering effect when welding aluminum and its alloys.

Furthermore, the inherent self-adjusting effect of the subsonic arc is more significant in MIG welding when welding aluminum and its alloys.

C. Spot welding

Spot welding is a welding process in which the contact surface and the surrounding area of the joint are melted by the resistance heat generated by the contact between the electrodes and the workpiece, and then solidified to form a spot weld.

It can be used for mixed welding of aluminum and iron, aluminum and copper, stainless steel and cast iron, but it is more difficult to spot weld aluminum and aluminum.

D. Brazing

Brazing is a method of joining two or more pieces of metal using a filler metal with a lower melting point than the base metal.

The filler metal melts and moistens the base metal by capillary action, forming a strong joint upon solidification.

Brazing requires heating and shielding to prevent the molten filler metal from coming into contact with air.

There are various types of brazing methods according to different heat sources and protection conditions, such as flame brazing, induction brazing, resistance furnace brazing, salt bath brazing, etc.

3. Composition of existing welding equipment and welding capabilities

Existing welding equipment can be divided into three types: spot welding machines, manual welding machines (MIG and TIG) and welding robots (MIG and TIG).

A. Spot welding machine:

Fixed Type C Spot Welding Machine:

Qilong 100KVA AC IC Synchronous Control Spot Welding Machine

Panasonic 100KVA AC Microcomputer Controlled Secondary Current Compensation Spot Welding Machine (Japanese technology, produced by Panasonic Tangshan)

The above spot welding machines can weld galvanized steel plates, cold-rolled steel plates, stainless steel plates, socket iron, hot-rolled steel plates, with a thickness range of 0.3 mm to 6 mm for overlapping joint of two plates.

Suspended Spot Welding Machine:

Quanxing brand 48KVA suspended spot welding machine (produced in Taiwan), can weld a plate thickness range of 0.2-3mm for lap joint of two plates.

Capacitor Storage Type Spot Welding Machine:

Pengyuwei 4500J capacitor storage type spot welding machine, can weld aluminum and aluminum alloy plates with a thickness of 0.4mm-3.0mm.

B. Manual MIG Welding Machine:

There are OTC 350P DC pulse MIG welding machines and American Flymat MIG350A welding machines, which can weld mild steel with a plate thickness of 0.8mm or greater, and aluminum and aluminum alloys with a thickness of 2mm or greater.

C. Manual TIG Welding Machine:

Hitachi HITACHI AC/DC dual-use pulse TIG welding machine, which can weld mild steel with plate thickness of 0.4mm or greater and aluminum and aluminum alloys with plate thickness of 1.0mm or greater.

D. MIG welding robot:

There are Swedish ABB MIG welding robots and Japanese company YAKAWA MOTOMAN WF200 MIG welding robots, which can weld galvanized steel plates, cold-rolled steel plates, stainless steel plates, horse mouth iron, hot-rolled steel plates , with a thickness range of 0.8 mm or greater.

E. TIG welding robot:

There are Swedish ABB TIG fillerless welding robots, which can weld galvanized steel plates, cold-rolled steel plates, stainless steel plates, horse mouth iron, hot-rolled steel plates with a thickness of 0.4 mm or more .

4. Welding notation

Welding symbols and welding method codes are standardized symbols or codes used in structural welding drawings and constitute a type of engineering language.

Welding symbols and welding method codes in China are defined in national standards GB324-88 “Method of Representation of Welding Symbols” and GB5185-85 “Codes of Representation of Welding and Allied Processes in Drawings.

These standards are basically consistent with the international standards ISO2553-84 “Method of Representation of Welding Symbols” and ISO4063-78 “Representation of Welding and Allied Processes in Diagrams”.

Therefore, they can be used interchangeably.

I. Welding Symbols

The GB324-88 “Method of Representation of Welding Symbols” standard specifies that welding symbols are applicable to both fusion welding and resistance welding.

The standard also specifies that to simplify the drawing, welding symbols should generally be used to represent the welds on the drawing, but technical drawing methods may also be used.

The welding symbols specified by the national standard include basic symbols, supplementary symbols and weld size symbols.

Welding symbols are generally made up of basic symbols and reference lines, and supplementary symbols, weld size symbols, and other symbols can be added as needed.

The basic symbols represent the cross-sectional shape of the weld. The 13 basic symbols specified in the GB324-88 standard are shown in Table 1-3.

Supplemental welding symbols represent surface characteristics of the weld. The three supplementary symbols specified in the GB324-88 standard are shown in Table 1-4.

Additional welding symbols are used to complement certain characteristics of the weld. Additional symbols specified in the GB324-88 standard are shown in Table 1-5.

Weld size symbols represent the characteristic dimensions of the groove and weld. The 16 size symbols specified in the GB324-88 standard are shown in Table 1-6.

Table 1-3: Basic Welding Symbols.

| Serial number | Name | Schematic diagram | Symbol |

| 1 | Edge welding (complete edge fusion) |

|

|

| two | I-shaped weld |  |

|

| 3 | V-shaped weld |  |

|

| 4 | One-sided V-shaped weld |  |

|

| 5 | V-shaped weld with blunt edge |  |

|

| 6 | One-sided V-shaped weld with blunt edge |  |

|

| 7 | U-shaped weld with blunt edge |  |

|

| 8 | J-shaped weld with blunt edge |  |

|

| 9 | seam welding |  |

|

| 10 | corner welding |  |

|

| 11 | Socket welding or slot welding |  |

|

| 12 | Welding point |  |

|

| 13 | Butt weld |  |

|

Table 1-4: Welding Auxiliary Symbols

| serial number | name | schematic diagram | symbol | instruction |

| 1 | Flat symbol |  |

Flush weld surface (usually achieved through machining) | |

| two | Concave symbol |  |

Concave welding surface | |

| 3 | Convex symbol |  |

Convex welding surface |

Table 1-5: Supplemental Welding Symbols

| serial number | name | schematic diagram | symbol | instruction |

| 1 | Grab bar symbol |  |

|

To indicate a weld with a support bar at the root |

| two | Spot welding symbol |  |

|

To indicate a weld on three sides |

| 3 | Circumferential Weld Symbol |  |

|

To indicate a weld around the circumference of a workpiece |

| 4 | Symbol on site |  |

To indicate welding carried out on site or in the field | |

| 5 | Tail symbol” is the translation for |  |

You can refer to the contents of GB5185 to mark welding process methods, etc. |

Table 1-6: Welding Dimension Symbols

| serial number | name | schematic diagram | serial number | name | schematic diagram |

| d | Part thickness |  |

oh | Bevel angle |  |

| B | Root gap |  |

I | Weld length” is the translation for |  |

| P | Blunt edge |  |

n | Weld Segment Number |  |

| w | Weld width |  |

It is | Weld spacing |  |

| d | Melting diameter |  |

K | Weld leg size |  |

| s | Effective throat thickness |  |

H | Groove depth |  |

| N | Quantity symbol for identical welds |  |

H | Reinforcement height |  |

| R | Root radius |  |

B | Groove face bevel angle |  |

2. Welding method codes

In order to simplify the marking and description of welding methods, various welding methods such as metal welding and _ welding can be represented by Arabic numerals specified in the national standard GB5185-85.

Table 1-7 shows the codes of commonly used welding methods specified in the national standard GB5185-85.

Table 1-7: Codes for the main commonly used welding methods.

| Welding Method Names | Welding Method Codes | Welding Method Names | Welding Method Codes |

| Arc welding | 1 | Pressure welding | 4 |

| Shielded Metal Arc Welding (SMAW) | 111 | Friction welding | 42 |

| Submerged Arc Welding (SAW) | 12 | Diffusion welding | 45 |

| Gas tungsten arc welding (GTAW) with inert gas shielding, also known as tungsten inert gas (TIG) welding | 131 | Other welding methods | 7 |

| Gas metal arc welding (GMAW) with inert gas shielding, also known as metal inert gas (MIG) welding | 135 | Electroslag Welding (ESW) | 72 |

| Gas metal arc welding (GMAW) with non-inert gas shielding, also known as Metal Active Gas (MAG) welding | 141 | Electrogas welding (EGW) | 73 |

| Plasma arc welding (PAW) | 15 | laser welding | 751 |

| Resistance welding | two | Electron beam welding | 76 |

| Spot welding | 21 | Pin welding | 78 |

| Seam welding | 22 | Hard welding | |

| Instant welding | 24 | Hard brazing | 9 |

| Resistance butt welding | 25 | Soft welding | 91 |

| Gas welding | 3 | Brazing. | 94 |

| Oxy-fuel welding. | 311 | – | – |

3. Placement of the welding symbol on the drawings

3.1 Basic Requirements:

The complete method of representing welds in drawings includes not only the basic symbols, auxiliary symbols, supplementary symbols, but also reference lines, some dimension symbols and data.

Welding symbols and welding method codes must be accurately represented through reference lines and relevant specifications.

Reference lines usually consist of two parts: an arrowhead line and two baseline parts (a solid line and a dashed line).

3.2 Relationship between Arrow and Joint:

The following figure provides an example of the meaning of the arrow side and non-arrow side of a joint:

The position of the arrow lines:

There is generally no special requirement for the position of the arrow lines in relation to the welds, but when indicating V, plain V, and J-shaped welds, the arrow line must point toward the side of the workpiece with the groove. If necessary, the arrow line can bend once.

3.4 Baseline Position:

The dashed baseline line can be drawn on the top or bottom side of the solid baseline line. The baseline should generally be parallel to the bottom edge of the drawing, but may also be perpendicular to the bottom edge under special conditions.

3.5 Position of Basic Symbols in relation to the Baseline:

If the weld and arrow line are on the same side of the joint, the basic weld symbol must be marked on the solid line side.

For example, as shown in the following figure:

If the weld is on the unarrowed side of the joint, then the basic weld symbol must be marked on the dashed line side of the baseline.

When marking symmetrical welds and double-sided welds, it is not necessary to add dashed lines.

4. Weld size symbols and their annotation positions:

4.1 The principles for marking symbols and weld size data are shown in the following figure:

The cross-sectional size of the weld is marked on the left side of the basic symbol.

The size in the length direction of the weld is marked on the right side of the basic symbol.

Sizes such as groove angle, groove face angle, and root clearance are marked on the top or bottom side of the basic symbol.

The symbol for the number of identical welds is marked on the tail.

When there are many size data that are difficult to distinguish, the corresponding size symbol can be added in front of the data.

The above principles remain unchanged when the direction of the arrow changes.

4.2 Explanation of dimension symbols:

The dimensions that determine the location of the weld are not given on the weld symbol, but are marked on the pattern.

When there is no notation or explanation on the right side of the basic symbol, it means that the weld is continuous along the entire length of the part.

When there is no annotation or explanation on the left side of the basic symbol, it means that the butt weld must be fully penetrated.

For plug welds and grooves with beveled edges, the bottom dimension of the hole must be indicated.

5. Welding manufacturing process

1. Understanding the drawing:

In the manufacturing process, when the process design people receive the drawing, the first step is to understand the structure of the part.

Based on this, understand the welding content required by the customer, including the welding location, the welding method to be used, whether polishing is required and other special requirements.

It is very important to understand the customer's intention, which determines the process flow that we will adopt later.

2. Determining the welding method:

In general, the customer's drawing already clearly marks the welding method and requirements: whether to use welding or spot welding, what the length of the welding seam should be, the size of the cross-section, etc.

However, in some cases, such as when we think it would be better to switch from welding to spot welding, we can confirm the change in welding method with the customer.

3. Determining the welding joint:

The most common welding joint is when the two sides of the part intersect vertically during self-welding. As shown in Figure 1 below:

Please note that in most cases, customers may not have considered weldability and the joint may not necessarily meet actual welding requirements.

Therefore, adjustments are often required when welding in cases such as 90-degree perpendicular joints.

As shown in Figures 2 and 3, Figure 2 is more suitable for TIG welding with thin materials (less than 2.0), while Figure 3 is suitable for MIG welding with thick materials.

As for the edge winding way, it can be determined based on the actual situation, generally considering the bending angle, and it is better to use the long side to wrap the short side.

4. Welding Positioning:

When welding two or more parts, a relationship is needed that can determine the position of each other, which is the positioning problem.

Depending on whether the part itself has a positioning structure, it can be divided into self-positioning and clamping positioning.

Below we describe these two types of positioning separately:

(1) Self-positioning:

A certain reserved protrusion or step is made on one workpiece, and the corresponding recess or hole is made on the other workpiece to realize positioning between the workpieces.

Currently, there are two most commonly used types: half shear – concave well positioning and cob – square channel positioning.

The typical structure of half-shear – concave well positioning is shown in the figure below.

In cases where the requirements are not high (such as when the welded surface of the workpiece is not visible), the concave well can be processed into a through hole, but it is strictly prohibited to drill a through hole if the workpiece is exposed abroad.

Another alternative structure of this method is to transform the circular half shear and concave well into a rectangle, but this is not recommended.

The processing of semi-sheared and concave pits is generally carried out in NCT. Both half-shear specifications, whether up or down, have tools.

There are no dedicated tools for front concave pits, but they can be processed through the use of combined tools.

There is a dedicated tool for reverse concave wells with a diameter of 3.1, but there are currently no tools for reverse concave wells with a diameter of 2.4 and they cannot be processed.

The method of using half shear – concave positioning has certain limitations: due to the adoption of half shear structure, the half shear effect is not ideal for thick plates (above T2.0), and the protruding part of the middle shear has an arc shape and cannot serve as a limiting function.

And because the concave pit is formed by the forced compression of the material, it can only be applied to relatively soft materials (such as AL, CRS, GI, etc.), and it is impossible to achieve this for harder materials (such as SPHC, SUS, etc. .).

In summary, this method is suitable for materials with a range of 2.0 mm or less of GI, CRS and AL sheet metal.

The positioning of the tenon – square groove is shown in the figure below:

When using this type of positioning method, the first step is to determine the specifications of the positioning slot.

If NCT cutting is used, it is best to consider that the square hole can be machined in one pass with NCT tools.

If laser cutting is used, the size can be determined based on the actual situation. Generally, the groove hole can be 0.1mm larger than the tenon, and the protruding part of the tenon should not exceed the thickness of the plate in the positioning groove.

The groove does not necessarily need to be a rectangular hole (closed type) and can be made open type depending on the specific situation.

(2) Application range of two self-positioning methods:

Comparing the above two positioning methods, it can be seen that when the welding surfaces of two workpieces are parallel to each other, the half-shear and concave well positioning method is better.

When the welding surfaces of two workpieces are perpendicular to each other, the tenon – square slot positioning method is more suitable.

(3) Positioning of the device:

If self-positioning does not meet the drawing requirements or high positioning requirements are required, a special clamping device will need to be made and cooperation with relevant departments (such as automation research and development) will be required.

5. Process requirements for spot welding :

(1) Total spot welding thickness:

The total thickness of spot welding should not exceed 8mm, and the size of the welding spot is generally 2T+3 (2T represents the thickness of the two welded parts).

Because the upper electrode is hollow and cooled by cooling water, the electrode cannot be reduced without limit, and the minimum diameter is generally 3 to 4 mm.

(2) Drilling and deburring of welding points:

The spot welding part must drill and deburr the welding points on one of the surfaces that are in contact with each other to increase the welding strength.

Normally, the burr size is Φ1.5-2.5mm and the height is about 0.3mm. Processing some small protrusions on one of the parts to be welded can improve the welding process.

As shown in the figure below, when the welding head presses the protrusion during the welding process and electricity is applied, the small protrusion melts, making the connection more firm and reliable.

(3) Distance between two welds:

As the thickness of the welded part increases, the distance between the two welds also increases.

If the distance is too small, the part is subject to overheating and deformation, while if it is too large, the joint strength may be insufficient and cracks may appear between the two parts.

Generally, the distance between two welds should not exceed 35mm (for materials below 2mm).

(4) Clearance between welded parts:

Before spot welding, the distance between the two parts generally should not exceed 0.8mm.

When the workpiece is bent and then spot welded, the position and height of the welds are very important.

If they are not placed correctly, the spot welding may become misaligned or deformed, resulting in greater errors.

(5) Surface damage caused by spot welding:

Burrs are easily formed at the spot welding point, which need to be polished and rust-proofed.

When necessary, the spot welding area can be coated with silver paint. If the spot welding area needs to be painted, it must be polished before painting.

(6) Spot welding of galvanized steel plates:

Galvanized steel plates mainly include galvanized plates, lead-coated plates, aluminum-coated plates and tin-coated plates, etc.

In production, spot welding of galvanized steel plates and galvanized parts is commonly found.

The thickness of the zinc layer is generally less than 20um.

Compared with spot welding of ordinary steel plates, the presence of zinc coating not only reduces the current density in the welding area, but also makes the current field distribution unstable.

Increasing current also further promotes the formation of Cu-Zn alloy on the working end face of the electrode, accelerating electrode wear and coating damage.

At the same time, the low-melting zinc coating causes cracks and pores to occur during the fusion zone crystallization process.

Therefore, the specification range of spot welding suitable for galvanized steel plates is narrow, and the joint strength fluctuates greatly, with poor weldability.

(7) Spot welding interference processing range:

The following is a schematic diagram of spot welding by a welding machine, with data indicating the processing range provided by the spot welding group on October 16, 2000.

Section 3: Hole Extrusion Riveting

1. Definition

Hole extrusion riveting is a process that connects two parts, one with a drilled hole and the other with a countersunk hole, using a riveting die to form an inseparable joint.

Advantages: Punching and reaming provide inherent positioning for the two parts. Hole extrusion riveting results in high joint strength and high efficiency through the use of specialized tools.

Countersunk Rivet Joint Datasheet

| Item number Serial number | Material thicknessT(mm) | Countersink heightH(mm) | Reamer outer diameter D(mm) | |||||||||||

| 3.0 | 3.8 | 4.0 | 4.8 | 5.0 | 6.0 | |||||||||

| Corresponding to the inner diameter of the pre-drilled hole countersink d0 | ||||||||||||||

| d | d0 | d | d0 | d | d0 | d | d0 | d | d0 | d | d0 | |||

| 1 | 0.5 | 1.2 | 2.4 | 1.5 | 3.2 | 2.4 | 3.4 | 2.6 | 4.2 | 3.4 | / | / | / | / |

| two | 0.8 | 2.0 | 2.3 | 0.7 | 3.1 | 1.8 | 3.3 | 2.1 | 4.1 | 2.9 | 4.3 | 3.2 | / | / |

| 3 | 1.0 | 2.4 | / | / | / | / | 3.2 | 1.8 | 4.0 | 2.7 | 4.2 | 2.9 | 5.2 | 4.0 |

| 4 | 1.2 | 2.7 | / | / | / | / | 3.0 | 1.2 | 3.8 | 2.3 | 4.0 | 2.5 | 5.0 | 3.6 |

| 5 | 1.5 | 3.2 | / | / | / | / | 2.8 | 1.0 | 3.6 | 1.7 | 3.8 | 2.0 | 4.8 | 3.2 |

Note: The general principle of countersunk riveting is H=T+T'+(0.3~0.4), D=D'-0.3 and Dd=0.8T. When T≧0.8mm, the countersunk wall thickness is 0.4T. When T<0.8mm, the thickness of the countersunk wall is generally 0.3mm. H' is generally considered to be 0.46±0.12.

Section 4: Pull Rivet Joint

1. Classification:

Pull rivets are divided into two types: flat head and round head (also known as umbrella head).

For flat head pull rivets, the side in contact with the rivet head must have a countersunk hole. For round head pull rivets, the contact surface is flat.

2. Definition:

Pull the rivet mandrel through the two through-hole parts using a rivet gun until it breaks, causing the outer sleeve of the rivet to expand and become a non-removable connection.

3. Parameters of pull rivet joint:

| Rivets category. | The nominal diameter of the rivet D | The diameter of the hole for riveting D1 steel plates | LengthL | M | Head diameter H | Head height P | Steel sheet thickness for riveting | Ultimate strength.(N) | |||

| Umbrella-shaped | Flat head | countersunk | flat head with shear resistance | Shear strength | tensile strength | ||||||

| Aluminum Blind Rivet | 2.4 | 2.5 | 5.7 7.3 8.9 |

1.42 | 4.8 | 0.7 | 0.8 | 1.0~3.2 3.2~4.8 4.8~6.4 |

1.6~3.2 3.2~4.8 4.8~6.4 |

490 | 735 |

| 3.0 | 3.1 | 6.3 8.0 9.8 |

1.83 | 6.0 | 0.9 | 1.0 | 1.0~3.2 3.2~4.8 4.8~6.4 |

1.6~3.2 3.2~4.8 4.8~6.4 |

735 | 1180 | |

| 3.2 | 3.3 | 6.3 8.0 9.8 |

1.83 | 6.4 | 0.9 | 1.1 | 1.6~3.2 3.2~4.8 4.8~6.4 |

1.6~3.2 3.2~4.8 4.8~6.4 |

930 | 1420 | |

| 4.0 | 4.1 | 6.9 8.6 10.4 |

2.28 | 8.0 | 1.2 | 1.4 | 1.2~3.2 3.2~4.8 4.8~6.4 |

1.6~3.2 3.2~4.8 4.8~6.4 |

1470 | 2210 | |

| aluminum pull rivet | 4.8 | 4.9 | 7.5 9.3 11.1 |

2.64 | 9.6 | 1.4 | 1.6 | 1.6~3.2 3.2~4.8 4.8~6.4 |

2.3~3.2 3.2~4.8 4.8~6.4 |

2260 | 3240 |

| steel pull rivet | 3.2 | 3.3 | 6.4 9.5 |

1.93 | 9.5 | 1.0 | 1.0~3.2 3.2~6.4 |

1270 | 1770 | ||

| 4.0 | 4.1 | 10.2 | 2.41 | 11.9 | 1.25 | 3.2~6.4 | 2060 | 2940 | |||

| 4.8 | 4.9 | 10.8 | 2.90 | 15.9 | 1.9 | 3.2~6.4 | 2750 | 3920 | |||

Note: The diameter of the rivet through hole in the part is generally 0.2 ~ 0.3 mm larger than the nominal diameter D of the rivet. The distance from the center of the rivet hole to the edge should be greater than 2 times the size of the rivet hole to obtain better rivet strength. If the distance is too small, the resistance will be greatly reduced.

4. Rivet Shape Diagram:

Observation:

(1) Flat head pull rivets are mainly used for surfaces with strict requirements where no protruding fasteners can be connected. The flat head of the pull rivet is recessed into a countersunk hole in the fastener so that the head does not protrude from the surface.

(2) The color of the pull rivet can be matched to the mounting part by blackening or other treatments to meet customer requirements. For example, the pull rivet head can be painted to allow riveting on painted parts.

5. For the most commonly used pull rivet, 3B010-01

It is the open end flat head pull rivet mentioned above. The outer diameter D of the rivet is 0.125 inches, i.e. 3.175 mm. The corresponding countersunk hole is Φ6.5XΦ3.5X120°, and the corresponding through hole is Φ3.4.