Traditional hub connecting devices typically rely on keys to join the hub and shaft, with keyways machined into both components.

Unfortunately, this practice weakens the strength of the shaft, increases manufacturing costs and can even make machining difficult.

To simplify the installation process, some engineers prefer keyless connections, where the hub and shaft are interference fit. During installation, the hub mounting hole expands through heating, or the installation shaft shrinks through cooling, thus creating the clearance necessary to fit the components.

However, this method presents problems when disassembling the components later.

As technology has developed, keyless connections between hubs have emerged that rely on tapered interference fit to achieve installation and torque transmission.

Expandable mechanical sleeves are inserted between the shaft and hub, and pinch screws are used to make the two mating tapered surfaces move relatively against each other, creating an interference fit between the mating surfaces of the two components.

This generates a strong clamping force between the hub and the shaft, allowing a keyless connection.

When the load is applied, the expanding sleeve, combined with the clamping pressure and the friction force generated between the hub and the shaft, transmits torque, axial force or combined loads.

However, traditional mechanical expandable sleeves have the following problems during use:

- Mechanical expandable sleeves consist of at least two components, and some even have up to five, making their manufacturing process very complex.

- Mechanical expandable sleeves require symmetrical tightening during installation, which involves using a torque wrench to tighten the screws in steps according to 1/4T, 1/2T, 3/4T and 1T of the rated torque. This process is time-consuming and laborious.

- As mechanical expandable sleeves age, the tapered surfaces between them rust more easily, making disassembly a challenge.

- Due to the relative sliding between mating tapered surfaces, the traditional connection method of mechanical expandable sleeves is subject to wear, especially when frequently assembled and disassembled. Furthermore, the assembly environment requires high levels of cleanliness, as even small dust particles can cause surface wear.

- The wall thickness of mechanical expandable bushings is uneven, and after the screws are tightened, the edges of the thin end will experience stress concentration, causing the shaft to crack or even break.

Fortunately, in recent years, a hydraulic expandable sleeve has emerged as an excellent solution to the limitations of mechanical expandable sleeves.

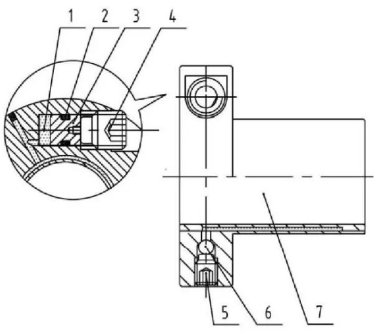

Just like mechanical expandable sleeves, hydraulic expandable sleeves are keyless connection devices. Still, its structure is totally different, mainly composed of the expandable sleeve body, regulating screw, piston, sealing ball, sealing screw and hydraulic oil.

The structure of the expandable sleeve body is complicated, consisting of a flange end and an inner and outer cylinder, which surround a hydraulic chamber for storing hydraulic medium that communicates with the piston chamber inside the flange end.

The specific structure is shown in the figure below.

1-Hydraulic means

2-O-ring

3-Pressurized piston

4-Pressure regulator screw

5-Sealing screw

6-Seal ball

Expansion sleeve main body 7

Working principle of hydraulic expandable sleeves:

Inject hydraulic medium into the sealed hydraulic chamber and tighten the regulating screw to compress the volume of hydraulic medium, creating uniform hydrostatic pressure.

This pressure causes the inner and outer cylinders to deform elastically, causing the inner cylinder to shrink and the outer cylinder to expand.

As the inner and outer cylinders fit snugly against the shaft and hub, the expandable sleeve continues to be compressed until it contacts the hub and shaft to generate positive contact pressure.

The load is then transmitted through the friction force generated at the contact surface. When the adjusting screw is loosened, the pressure in the hydraulic chamber gradually decreases to zero, and the inner and outer cylinders quickly return to their initial state in an elastic manner, separating the expandable sleeve from the shaft and hub.

In this way, it is possible to quickly disassemble the axle and hub bore.

The operating status is shown in the figure below.

Features of hydraulic expansion sleeve

In addition to the advantages of traditional mechanical expandable sleeves, hydraulic expandable sleeves also have their own characteristics:

Faster installation and disassembly.

By compressing the liquid to generate high hydrostatic pressure, the expandable hydraulic sleeve comes into contact with the hub and shaft to transmit the load through contact pressure.

Hydraulic pressure can be produced with just one screw, which makes its installation and disassembly efficiency at least six times that of tapered roller bearings, as shown in Figure (a).

High positioning accuracy.

Traditional mechanical expandable sleeves generate axial force during pre-tightening, affecting axial positioning accuracy.

In contrast, hydraulic expandable sleeves rely on the contact pressure generated by the contact surfaces to transmit friction torque and axial loads, not only improving axial positioning accuracy, but also having unparalleled advantages in situations with high requirements for positioning accuracy. axial positioning, as shown in Figure (b).

Space saving along the axial direction.

By designing a flange end that can accommodate adjusting screws and pistons, hydraulic expandable sleeves break the constraints of conventional expandable sleeve structure and allow for radial installation and disassembly without requiring axial operating space for the expandable sleeve, as shown in Figure (w ).

Small radial pulsation.

Traditional mechanical expandable bushings consist of an inner and outer cone bushing, while the hydraulic expandable bushing is a completely integrated structure, greatly reducing the radial pulsation of the hub during operation, as shown in Figure (d).

Through the above advantages and working principles, we can recognize that hydraulic expandable sleeves have unique advantages in design, use and disassembly, making them irreplaceable with traditional expandable sleeves.