Some polymers, metals and ceramics are better suited to additive manufacturing (AM) processes than other materials. There are also certain differences between the various AM methods.

As the mechanical properties of additively manufactured parts continue to improve, AM is gradually gaining recognition in many application fields. Therefore, various materials suitable for AM have received more attention from the industry, and the materials are inseparable from AM processes.

The same applies to traditional manufacturing methods – as is known, not all materials can be welded or cast because the material must be compatible with the appropriate process, and vice versa, this also applies to AM.

The manufacturing process and raw materials must be considered together. For readers interested in AM materials, if they want more information, they can refer to a recently published review article on this topic in reference 1.

In 2016, sales of additive manufacturing materials were $900 million, a 17% increase from the previous year. Since 2010, sales of additive manufacturing materials have grown linearly, and by 2025, sales of additive manufacturing materials are expected to reach $5-8 billion.

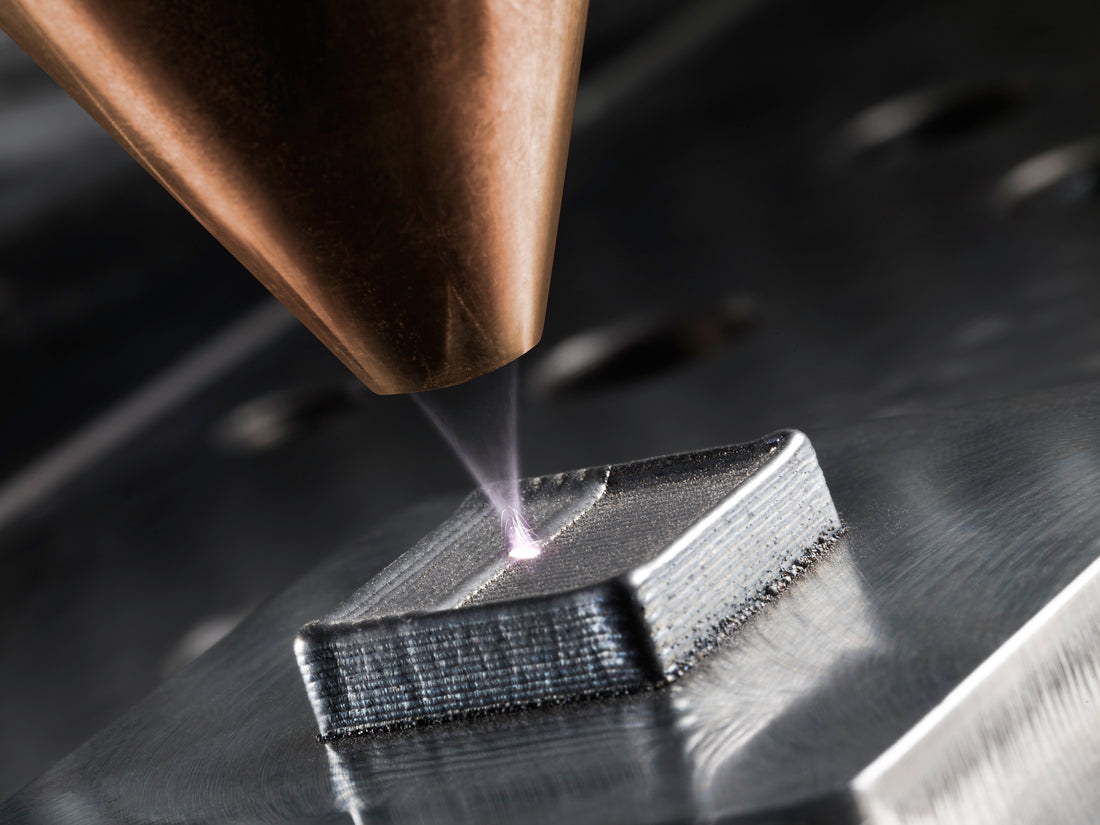

The Additive Manufacturing Alliance has currently divided AM processes into seven categories (see table). Three processes that require the use of lasers are: Powder Bed Fusion (PBF), Directed Energy Deposition (DED) and Vat Photopolymerization.

For Powder Bed Fusion (PBF), a thin layer of powder is first spread onto the substrate and a computer-controlled laser beam scans the surface of the powder. Then another layer of powder is added, scanned and the process is repeated. In Directed Energy Deposition (DED) processes, the powder or wire enters the energy source (laser or electron beam) from the side.

Both powder bed fusion and directed energy deposition typically use 50-500 W lasers to heat and melt materials. Vat photopolymerization uses milliwatt-level lasers with specific wavelengths to achieve photo-induced cross-linking in liquid thermosetting polymeric materials.

Polymeric materials for additive manufacturing

According to a report from Wohlers, an additive manufacturing research institution, in 2016, 46% of all AM polymers consumed were vat photopolymerization resins and material deposition thermoset resins.

Among the materials used for extrusion processes, amorphous polymers represented 24%, and among the materials used for powder bed fusion processes, semicrystalline thermoplastic plastics represented 30%.

The polymers used in powder bed fusion processes are generally semi-crystalline thermoplastic plastics such as polyamide, PEEK and TPU. Amorphous thermoplastic plastics generally do not perform well because their melting temperature has a large viscosity range, minimizing the process temperature range and often resulting in high viscosity solutions that are not desirable in bed fusion processes. of dust.

A wider melting temperature range can also lead to over-sintering of parts. Figure 1 shows an example of using amorphous PLA powder for laser sintering processes, which did not produce ideal results.

An important characteristic of semicrystalline polymers used in powder bed fusion processes is the difference between their high melting point when heated and low crystallization temperature when cooled.

This temperature window must be large enough so that the powder bed fusion build chamber is heated to just below the melting point of the polymer, and the build temperature is low enough to prevent agglomeration of the powder layer.

This temperature must be within the temperature range above the crystallization moisture and below the melting point.

When the laser sweeps and melts the powder, it cools to the temperature of the build chamber but maintains its molten structure because it has not reached the crystallization temperature. Therefore, the melted part stays melted.

Typically, after placing multiple layers of powder on top, they slowly crystallize, which has significant advantages in reducing residual stress and minimizing part deformation. However, this phenomenon is generally impossible for metals and requires a large amount of support structures to prevent deformation of parts during construction.

Hopkinson proposed a new metal manufacturing method in which alloy raw materials are split into two high-melting point components. When the laser (or electron beam) scans and melts the material, a metal with a lower melting point (such as eutectic) is formed and held in a molten state. This method mimics the polymer method and eliminates the need for supports.

For extrusion-based processes, high viscosity paste polymers are better controlled for extrusion and material placement.

Common polymeric materials suitable for this process are amorphous materials (such as PLA, ABS and polyamide). Attempts to use semicrystalline materials during material extrusion often result in lower quality structures, similar to creating multilayer parts with chocolate or PEEK.

The polymers used for vat photopolymerization and material blasting processes are generally thermosetting polymers that contain photoinitiators that can achieve cross-linking under certain light wavelength conditions. The first commercial materials were all based on acrylic acid esters, but epoxy resins were introduced because these materials had greater shrinkage and the harmful effects of oxygen.

Metal materials used for additive manufacturing

The general rule for metallic materials used in additive manufacturing is that if a metal is suitable for welding or casting, it is likely to be suitable for additive manufacturing.

Except for thin sheet lamination processes (such as ultrasonic additive manufacturing, which uses an ultrasonic generator to form a solid-state weld between metal sheets before processing) and metal adhesive jet processes (in which an adhesive is sprayed onto a bed of metal powder), the metal additive manufacturing process mainly relies on melting.

Base metal additive manufacturing alloy materials.

Alloys commonly used for additive manufacturing are also suitable for welding/casting, including Ti-6Al-4V, AlSi10Mg, 316L stainless steel, and CoNiCr. When metals with limited weldability/castability are used in additive manufacturing, the resulting parts typically have high defects.

The case of using 6061 aluminum alloy material for additive manufacturing in National Standard GB/T 5237.5-2019 illustrates this point: the material used is pre-alloyed Al6061, which is an AlMgSi alloy with a wide solidification temperature range and a higher coefficient of thermal expansion resistance, both of which can cause vertical (z-direction) fractures at grain boundaries during solidification.

Mixing Mg2Si particles into pure aluminum powder raw materials can prevent cracks in parts produced by additive manufacturing. In this case, the solidification/melting characteristics of the raw materials are dominated by pure aluminum because Mg2Si does not melt during laser scanning.

As shown in Figure 2b, no cracks were observed when weldable pure aluminum material was used.

Furthermore, which metal alloy may be suitable for the additive manufacturing process depends on the conditions and equipment used.

For example, it has been reported that Renishaw's additive manufacturing machines can handle Al6061 materials successfully, while EOS DMLS machines cannot process this material without cracking.

The mechanical properties of ceramics depend on the inherent behavior of the material and the size and distribution of defects. Weibull statistics are typically used to describe the strength of ceramics.

The most common term is Weibull Modulus, which describes the stress range where brittle failure can occur.

A lower Weibull Modulus indicates a wider range of failure stresses, making it difficult to predict the failure voltage of a specific component: a higher Weibull Modulus is more ideal as it implies a smaller range of failure stresses and therefore a prediction easier failure voltage for specific components.

In many cases, ceramic components produced by additive manufacturing have lower Weibull moduli compared to traditional pressed and sintered ceramic parts. However, as larger defects are eliminated, the Weibull Modulus also increases.

Mechanical Properties of Additively Manufactured Materials

Parts produced by additive manufacturing are typically as hard and strong as, if not better than, those produced by traditional machining methods. This is often related to the fine microstructure generated by additive manufacturing.

The modulus of elasticity of additively manufactured parts is generally equal to or slightly lower than manual values. This is largely attributed to residual porosity, which reduces modulus.

Table of types of processes for using lasers

| Process Type | Use of Lasers | Available Materials |

|---|---|---|

| Powder bed fusion | Yes | Metals, polymers, ceramics |

| Directed energy deposition | Yes | Metal |

| Photopolymerization in containers | Yes | polymer, cermet |

| Fine lamination | ** | Metals, polymers, ceramics |

| Adhesive spraying | ** | Metals, polymers, ceramics |

| Material spraying | No | Polymer |

| Material extrusion | No | Polymer |

The ductility (fatigue resistance limit and fracture resistance) of additively manufactured parts is generally lower, which appears to be related to the extent of the defect structure. Removing defects from additively manufactured parts (e.g., through hot isostatic pressing of metals) can often restore these mechanical properties to manual values.

An exception is the ductility of powder bed cast polymers. In the additive manufacturing process, long-chain polymers do not mix at the particle boundaries of the raw material, while in injection molding, long-chain polymers mix completely due to shear.

For example, additively manufactured polyamides (nylons) have a breaking strength of about 50%, while injection molded polyamides have a breaking strength of 200-400%.