Mechanical looseness is generally classified into two categories: structural looseness and rotating component looseness.

Reasons for mechanical play may include poor installation, prolonged wear, damage to the foundation or base, damaged parts, excessive play in fit, and so on.

Mechanical looseness can worsen vibration problems caused by imbalances and misalignments, and can also lead to further failures due to progression of the looseness.

There is no definitive standard to define the types of laxity.

Currently, there are three common types of mechanical looseness, each with its own vibration frequency spectrum and vibration phase characteristics.

1. Type A: loose structure and foundation

1. Loose phenomenon and treatment measures

This type of laxity encompasses the following faults:

• Loose structures or inadequate strength in equipment base, base plate and concrete foundation.

• Deterioration or breakage of the mortar.

• Deformation of the frame or base.

• Loose anchor bolts, etc.

These looseness problems can be easily observed on site and their destructive impact is often significant. In serious cases, they can worsen equipment imbalances or misalignments.

Treatment measures:

- Strengthening the foundation and correcting the structure.

- Tighten loose screws, etc.

For equipment that is already unbalanced or misaligned, it is important to address the imbalance or misalignment simultaneously.

2. Typical loosening frequency spectrum and basic characteristics

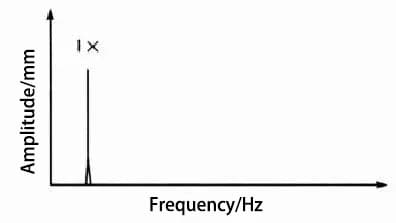

The typical frequency spectrum of looseness is depicted in Figure 1, and the fundamental characteristics revealed by looseness are presented in Table 1.

Fig. 1 Typical type A loosening spectrum diagram

Table 1 Basic Characteristics Reflected by Type A Laxity

| Parameter | Basic characteristics |

| Frequency | The loosening frequency spectrum is dominated by 1× higher back frequency vibration |

| Vibration | Generally, the radial vibration is large, especially the vertical vibration is large, and the axial vibration is small or normal |

| Internship | Comparing the vibration in the vertical and horizontal directions, it is found that the vibration has directivity, and the phase difference is 0° or 180° |

Grades:

- This typical looseness characteristic is comparable to vibration caused by an unbalanced or eccentric rotor, and can be differentiated based on phase.

- Typically, high vibration is concentrated in just one rotor (such as the driver, driven machine, or gearbox), which distinguishes it from imbalance or misalignment, as the high vibration caused by these problems is not limited to just one rotor.

- In some exceptional cases, such as screws used to secure the pump bearing seat, the force is in the axial direction. If these screws become loose, 1x speed axial vibration will be elevated, resembling a misalignment failure. However, once these screws are tightened, vibration will be reduced.

2. Type B: looseness caused by rolling movement or structural fracture and bearing pedestal fracture

1. Loose phenomenon and treatment measures

This type of laxity only occurs when the following faults occur:

- A damaged structure or support base.

- An instability caused by unequal lengths of the supporting feet, sometimes.

- Loose bearing seat bolts in rare cases.

- Minor assembly issues with loose bearings or unsuitable parts (no significant impact).

These clearance problems can also be observed on site, but internal component mismatch problems can only be detected and confirmed through disassembly and examination.

Treatment measures:

Vibration can be reduced by replacing damaged parts, correcting the fit of incorrect parts, tightening screws, etc.

2. Typical loosening frequency spectrum and basic characteristics

The typical frequency spectrum of looseness is represented in Figure 2, and the fundamental characteristics reflected by looseness are presented in Table 2.

Fig. 2 Typical type B loosening spectrum diagram

Table 2 Basic Characteristics Reflected by Type B Laxity

| Parameter | Basic characteristics |

| Frequency | Multi-turn frequency harmonics, when the amplitude of the 2x turn radial frequency exceeds 50% of the amplitude of the 1x turn frequency, indicates that such a failure occurs. |

| Vibration | The amplitude is somewhat unstable. When the load is high, the vibration increases greatly. |

| Internship | If a strobe lamp is used to collect phase readings, two unstable reference points will typically be displayed. |

Grades:

• Under normal conditions, these vibration symptoms will not occur if there are no other excitation forces.

• If the play is caused by the bearing loose on the bearing pedestal or loose parts on the shaft, the vibration will remain mainly at 1x and 2x speeds until it turns into pulsation or impact.

In this case, pulsation will result in nonlinearity of the time domain waveform, leading to many harmonics that are more severe than Type C looseness.

• Sometimes, coupling failure is further aggravated by fracture and looseness of the equipment foot, causing wear and looseness in the coupling's elastic block. This spectrum also exhibits harmonics that overcome the looseness of Type C.

3. Type C: play caused by loose bearings or inadequate fit between components

1. Loose phenomenon and treatment measures

This type of laxity encompasses the following faults:

• Loose bearings in the bearing pedestal.

• Excessive internal play in the bearings.

• Loose bearing bushings in the bearing seat.

• Loose rotor.

• Loose bearings or bearing rings, etc.

These problems can be observed by opening the bearing pedestal end cover. This type of clearance is directly associated with the bearings and shafts of rotating equipment.

When play is severe, bearings, shafts or mating parts will wear out, or in severe cases, rotating equipment may become completely blocked.

Treatment measures:

It can be resolved by replacing the bearing or bushing and adjusting the fit between the components.

2. Typical loosening frequency spectrum and basic characteristics

The typical loosening frequency spectrum is shown in Fig. 3, and the basic characteristics reflected by its loosening are shown in Table 3.

Fig. 3 Typical type C loosening spectrum diagram

Table 3 Basic Characteristics Reflected by Type C Laxity

| Parameter | Basic characteristics |

| Frequency | The harmonics of multiple frequency conversion sometimes reach 10× or even 20×, which is very obvious in the spectrum. If the harmonic amplitude becomes larger, the frequency component with a range of 1/2 times the frequency will also be generated (i.e., 0.5×, 1.5×, 2.5×). Sometimes there is up to 1/3 of the frequency conversion harmonic. |

| Vibration | This looseness tends to produce highly directional vibration with relatively high amplitude. |

| Internship | Generally, the phase measurement of this type of loose fault is somewhat unstable, but if the vibration itself becomes highly directional, the difference between the horizontal and vertical directions will be close to 0° or 180°. |

Grades:

• Backlash can also occur after the component has reached its operating temperature and has undergone thermal expansion.

• The presence of a distinct 1/2x peak suggests that a more complex loosening problem is present, possibly involving friction.

• When the rotor, like the impeller of a pump, is loose, the phase changes after each start.

• The vibration spectrum of this type of looseness, characterized by many 1×speed harmonics, actually indicates a more serious problem, such as looseness in the bearings and ring function.

This problem can result in shaft binding and significant equipment failure.