Arc welding robots may have been unknown to many, including me, before this! Don't confuse this robot's name with a children's toy or a Transformer-like toy!

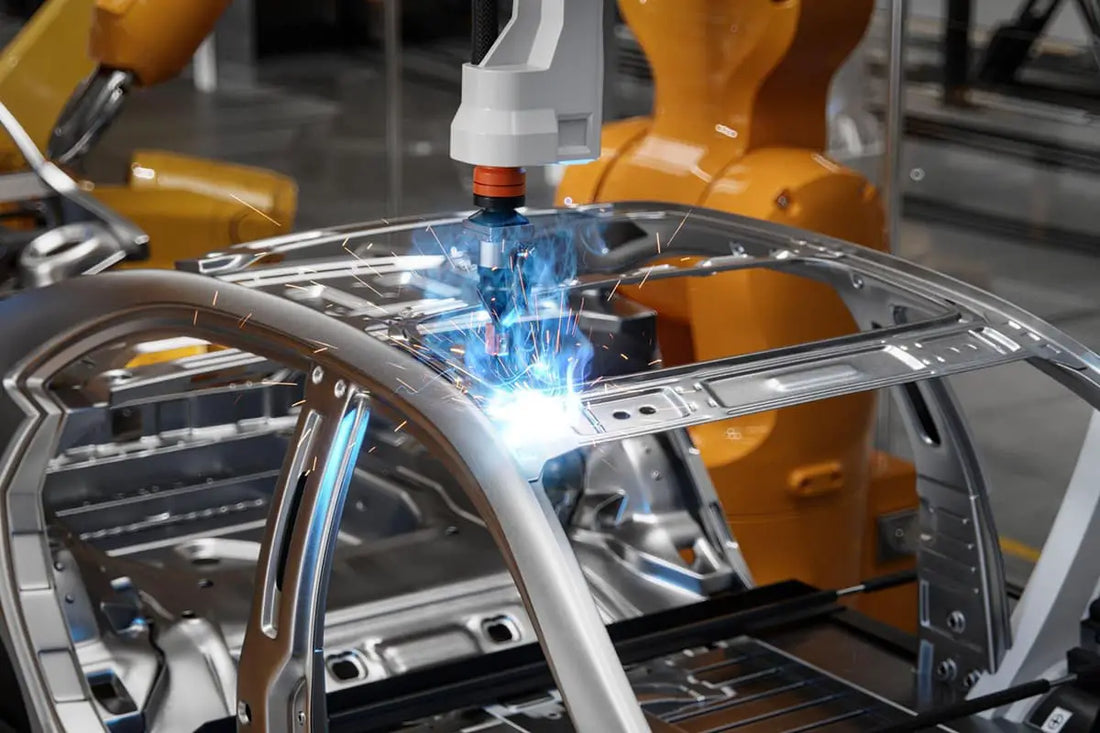

In fact, an arc welding robot is a kind of industrial robot.

The main function of an arc welding robot is to perform automatic arc welding, which means using a robot for automated welding, replacing traditional manual welding by welders.

If you have studied arc welding robots, you will know that their principle is quite similar to that of spot welding robots.

As early as the mid-1980s, China invented the first generation of arc welding robots for industrial use. It consists of five main parts: a control panel, the robot itself and an automatic wire feeding device.

Under the precise calculation and control of a computer, it realizes continuous stroke control and point control. Compared with the operation of ordinary welders, arc welding robots are more efficient and faster, and most importantly, the welding process is more precise.

The basic components of a robotic arc welding system include the robot body, control system, teaching device, welding power source, welding torch, welding accessory and safety protection facilities.

Obviously, system components can be selectively expanded based on different welding methods and specific welding process requirements of the workpiece to be welded, such as wire feeder, wire cleaning and cutting device, cooling water tank, flux supply and recovery device (when SAW), mobile device, welding positioner, sensors, dust removal device and so on.

The main operating modes of arc welding robots are divided into two types, both of which can perform long-term welding, thus ensuring high efficiency and quality of operation.

Compared with other welding methods, the stability of this mode is unparalleled. In recent years, with the continuous development and expansion of technology, arc welding robots have constantly evolved towards digitalization.

With the inclusion of arc welding robots, the efficiency of the entire electric welding connection process and the technical requirements of products have been improved, and this technology will be increasingly used by more industries, gradually forming unmanned factory operations.

How should we operate after purchasing an arc welding robot? We have never operated it before. Are there any safety concerns initially? I will now discuss the safety operation standards for arc welding robots, providing a clear understanding of correct operation to avoid injuries.

Before production, we must inspect whether the equipment is in good condition, and then check the safety of the place where the arc welding robot will be used. If everything appears normal after inspection, we can turn on the main power. Once the main switch is on, we need to check if the current and voltage indicators are working properly.

If they appear normally, we can open the shielding gas cylinder valve and check its status. We also need to open the air source valve and check its normality. If everything is ok, we can start work.

Main technologies of arc welding robots

1. Optimized integration of robotic arc welding systems:

The arc welding robot implements alternating current servo drive technology along with high-precision, high-rigidity RV speed reducers and harmonic drives. This ensures excellent stability at low speed and dynamic response at high speed, enabling maintenance-free operation.

2. Coordinated control technology:

This allows for synchronized movement of multiple robots and positioners, maintaining the relative posture of the welding torch and workpiece to meet the requirements of the welding process, while also preventing collision between the torch and the workpiece.

3. Accurate weld seam tracking technology:

This combines the advantages of offline operation of laser and vision sensors. The laser sensor is used for seam tracking during the welding process, increasing the robot's flexibility and adaptability when welding complex parts. The vision sensor is used offline to observe the residual seam tracking deviation.

Based on deviation statistics, compensation data is obtained and used to correct the robot's motion path, ensuring optimal welding quality under various conditions.

After the arc welding robot operation is completed, we first need to close the gas valve, then the gas cylinder, followed by the main switch, all in that order. After shutdown, the machine must be cleaned and tidied up, followed by another inspection to ensure that the arc welding robot was not damaged during production.