CNC tools include various motorized machines and tools that use pre-programmed software to automate and control various machining operations. These machines play a central role in the manufacturing industry. The cutter used in CNC milling operations fundamentally affects the finish of large, flat surfaces. Here we will look in detail at the types, specifications and applications of milling cutters.

Impact milling cutter – definition

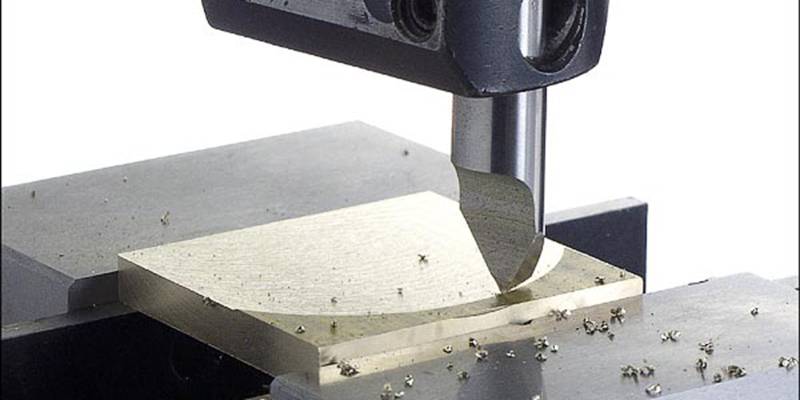

Impact cutters are rotary cutting tools used with sideways motion to machine and produce finished flat surfaces. Although these useful tools can be used on a variety of machines, they are mainly used on CNC milling machines.

For example, impact cutters use one or more single-edge tools, also called impact cutting bits, that are inserted into the cylindrical body. Impact cutters are mounted on a special angle bracket so that as the entire unit rotates, these bits perform surface cuts in soft materials such as aluminum and hard materials such as steel.

In addition, certain types of milling cutters are suitable, such as: B. the rotary cutting tool, for cutting, drilling, grinding, carving and grinding work. However, remember that impact cutters are better suited for light cutting jobs rather than heavy cutting jobs.

Types of impact cutters

Most impact cutters are designed and manufactured to meet industrial specifications. However, different types of impact cutters differ in important aspects such as cutting material, feed rate and cutting speed. Therefore, depending on the machining project, it is necessary to choose the types of cutters suitable for finishing large and flat surfaces. Let's take a closer look at common types of impact mowers.

1. Tip Cutter

As the name suggests, this fly clipper consists of needle-like tips designed to cut through densely populated corals. Most top cutters have two cutting edges per blade, and these ground edges help produce precise cuts during milling. Plus, edge cutters reach hard-to-reach areas and slide in and out of the handle for secure storage. Depending on the project, you can choose a long (500 mm) or short (300 mm) blade.

2. Rotary cutting tool

With this cutter you can quickly cut, pierce and sand various fabrics without altering the pattern line. Experts sometimes use the rotary cutting tool to cut up to eight layers of fabric in just one milling session.

3. Rotary Carving Tool

Rotary carving tools are typically used to carve hard materials. More specifically, manufacturers use this type of impact cutter to carve wood fibers or engrave blown glass.

Impact Cutter Components and Specifications

Impact cutters have unique features and specifications. Check it out below:

Impact Cutter Components

Typical impact cutters consist of the following parts:

- Cylindrical body

- support

- thrust washer

- Fasteners

- tension screw

- A left-handed carbide cutting tool

In most cases, the centrally placed cylindrical body of the impact cutter holds a tool bit. Impact mills with two tool tips, on the other hand, are often clamped with a tool tip on each end. Before use, these impact cutting bits are fixed in a special angle bracket at right angles (90 degrees) to the main axis of the bar. In addition, the left-handed carbide tool is generally held at an angle of 30 to 60 degrees.

Impact Cutter Specifications and Size

Impact cutters work in different ways. Depending on the nature of your milling project, you will need to ensure that each impact cutter receives sufficient power from your milling machine. The rotary cutting tool, for example, has a variable speed motor for light to heavy cutting jobs, with power from 0 to 30,000 rpm.

Please note that for each impact cutter body length, a specific bit length is used to achieve optimal results. For example, the main body of a rotary cutting tool has a shaft lock that allows the 1/8″ collet to be opened and closed for standard rotary purposes. Below are some other important rules of thumb to remember:

- The Body Fresh 3/4″ router uses a 3/16″ tool attachment.

- The 1-1/8″ body uses a 1/4″ tool attachment.

- The 1-3/8″ body mill uses a 5/16″ tool attachment.

Impact cutter vs. face milling cutter: What are the differences?

In general, face milling involves milling flat or flat surfaces positioned perpendicular to the axis of rotation of the cutter to produce a high-quality surface finish. Face mills and impact mills differ in certain aspects. Here are some of the differences:

1. Number of missions

Impact mills use one or two inserts at slower cutting speeds to remove excess parts during milling operations. Face mills, on the other hand, use multiple inserts at higher cutting speeds, making them better for removing large amounts of material. However, the insert height of face mills cannot be adjusted separately, resulting in different chip loads between different inserts.

2. Quality of finish

Front milling provides high-quality surfaces. Meanwhile, impact cutters use fewer finish cutting techniques to achieve a much finer finish. Still, a large face mill is the best choice for high-volume projects because it offers the highest speed per pass.

3. Cutting Requirements

The cutting edge of correctly positioned impact mills can cover large areas in a milling process, creating a very flat surface. Face mills, on the other hand, have cutting edges of different heights and are therefore more suitable for producing grooved surfaces.

4. Costs

Face mills require heavier, stiffer and more powerful machines with high spindle power, which makes them expensive. In contrast, impact cutters work well for smaller machines with lower spindle power and are much less expensive. Furthermore, the greater the stakes required, the greater the operating costs. Impact cutters are therefore economical compared to face mills that require one or two inserts.

Impact cutter considerations for surface finishing

Impact milling tools have become indispensable for surface processing. However, there are some specific factors to consider before using these tools. Keep the following considerations in mind:

Beater knife maintenance

If you are operating a small or lightweight milling machine, consider using single-tooth impact mills for best performance. On the other hand, multi-tooth impact mills do not work optimally on smaller machines because they do not have the power and rigidity needed to drive each tooth through the workpiece.

It is also important that the impact cutter is sharp enough to make cuts without additional force to overcome challenges and achieve ideal end results. However, you can still sharpen the tool after a long period of use by simply sanding it.

Point radius

Professional machine operators keep the impact cutter tip radius less than 1.5 mm. Because the smaller the tip radius, the slower the feed rate, resulting in a fine finish. Therefore, avoid large nose radii, as these increase the cutting pressure of the tool and lead to deflections. Ultimately, this leads to creaking, rattling, and poor end results.

Workpiece type

When using impact cutters on steel grades such as 1018, it is best to use carbide drills with no rake angle and a surface relief of approximately 5 degrees. However, for aluminum materials such as 6061-TS, experts use high-speed impact drills to grind a draft angle of about 60 degrees into the surface from the end.

Furthermore, most machinists tend to set the diameter of normal impact cutters up to 51 mm. With this diameter set, you can easily use the impact cutter to make a 0.25mm deep cut in aluminum.

Application areas of impact cutters

Impact cutters are used in many industries today. In these industries, these power tools are typically used in CNC tools and hand milling machines without the need for additional chucks. Therefore, impact cutters are often used to remove a large amount of excess material from the part and then smooth it. Most manufacturers use impact cutters for many materials, including metals, wood and glass.

WayKen helps you choose the right milling cutter for milling projects

There are different types of impact cutters and each type has its advantages, compatibilities and limitations that you must consider carefully. Of course, you can also consult an expert for professional advice.

University Degree

Today, CNC milling is used in many manufacturing industries to ensure high levels of precision and accuracy, efficiency and consistency in machining operations. Impact cutters are important rotary cutting tools that have one or more bits inserted into the body. These tools are mainly used on CNC milling machines for machining and leveling large, flat surfaces, such as: B. face milling cutter. This article will help you choose the right impact milling cutter for your milling project.

Common questions

How do I choose a milling tool?

It is necessary to consider important factors such as the type of material, the dimensions of the internal and external profiles (round vs. chamfer) and the type of finish desired for the piece.

Why is synchronous milling generally avoided?

When milling, it is more difficult to clamp chips between the tool and the workpiece. Furthermore, chips are easily discarded by the rotating movement of impact cutters.

Can you drill a hole with an impact cutter?

Yes, you can mill a hole with an impact mill. You can adjust the diameter of the rotary impact cutter to the desired hole size before inserting it into the CNC router for drilling.