What is steel beam?

Hot-rolled common I-beams, also known as steel beams, are long steel bars with an I-shaped cross section. The specifications of I-beams include sizes such as 8#, 10#, 12#, 14#, 16#, 18#, 20a, 20b, 22a, 22b, 25a, 25b, 28a, 28b, 30a, 30b and more.

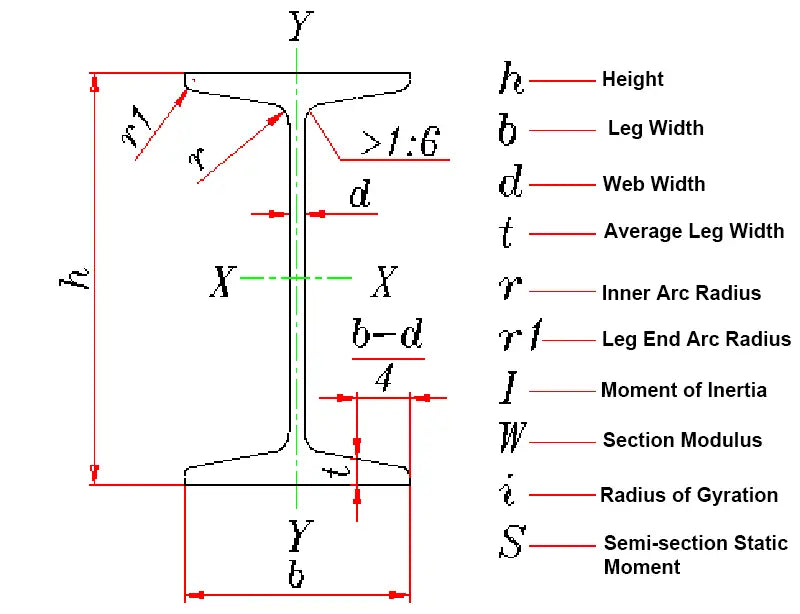

Its cross-sectional dimensions are represented by web height (h) x web thickness (d) in millimeters. For example, an I beam with a web height of 160 mm, a flange width of 88 mm and a web thickness of 6 mm is denoted as “I-160x88x6”. Another way to mark I beams is using the web height in centimeters, such as I-16#.

I-beams with the same web height but different web thicknesses and flange widths are distinguished by adding a, b, or c after the size, such as 32a#, 32b#, 32c#, etc.

Primary uses: Similar to common I-beams, they are primarily used in large structural components such as factory buildings and bridges, as well as in the manufacture of vehicles and ships.

I Beam standard size and weight chart

The table provided can be used as a reference guide for standard sizes in mm and weight of I-beams in kg.

1. Size and weight table of common hot rolled I beams

| Specifications. |

Height (mm) |

Flange Width (mm) |

Web thickness (mm) |

Theoretical Weight (kg/m) |

|---|---|---|---|---|

| 10 | 100 | 68 | 4.5 | 11,261 |

| 12.6 | 126 | 74 | 5 | 14,223 |

| 14 | 140 | 80 | 5.5 | 16.89 |

| 16 | 160 | 88 | 6 | 20,513 |

| 18 | 180 | 94 | 6.5 | 24,143 |

| 8pm | 200 | 100 | 7 | 27,929 |

| 20b | 200 | 102 | 9 | 31,069 |

| 22a | 220 | 110 | 7.5 | 33.07 |

| 22b | 220 | 112 | 9.5 | 36,524 |

| 25a | 250 | 116 | 8 | 38,105 |

| 25b | 250 | 118 | 10 | 42.03 |

| 28a | 280 | 122 | 8.5 | 43,492 |

| 28b | 280 | 124 | 10.5 | 47,888 |

| 32a | 320 | 130 | 9.5 | 52,717 |

| 32b | 320 | 132 | 11.5 | 57,741 |

| 32c | 320 | 134 | 13.5 | 62,765 |

| 36a | 360 | 136 | 10 | 60,037 |

| 36b | 360 | 138 | 12 | 65,689 |

| 36c | 360 | 140 | 14 | 71,341 |

| 40a | 400 | 142 | 10.5 | 67,598 |

| 40b | 400 | 144 | 12.5 | 73,878 |

| 40c | 400 | 146 | 14.5 | 80,158 |

| 45a | 450 | 150 | 11.5 | 80.42 |

| 45b | 450 | 152 | 13.5 | 87,485 |

| 45c | 450 | 154 | 15.5 | 94.55 |

| 50a | 500 | 158 | 12 | 93,654 |

| 50b | 500 | 160 | 14 | 101,504 |

| 50 cents | 500 | 162 | 16 | 109,354 |

| 56a | 560 | 166 | 12.5 | 106,316 |

| 56b | 560 | 168 | 14.5 | 115,108 |

| 56c | 560 | 170 | 16.5 | 123.9 |

| 63a | 630 | 176 | 13 | 121,407 |

| 63b | 630 | 178 | 15 | 131,298 |

| 63c | 630 | 180 | 17 | 141,189 |

2. Light Duty Hot Rolled I Beam Size and Weight Chart

| Specifications. |

Height (mm) |

Flange Width (mm) |

Web thickness (mm) |

Theoretical Weight (kg/m) |

|---|---|---|---|---|

| 8 | 80 | 50 | 4.5 | 7.52 |

| 10 | 100 | 55 | 4.5 | 9:46 am |

| 12 | 120 | 64 | 4.8 | 11.5 |

| 14 | 140 | 73 | 4.9 | 13.7 |

| 16 | 160 | 81 | 5 | 15.9 |

| 18 | 180 | 90 | 5.1 | 18.4 |

| 18a | 180 | 100 | 5.1 | 19.9 |

| 20 | 200 | 100 | 5.2 | 21 |

| 8pm | 200 | 110 | 5.2 | 22.7 |

| 22 | 220 | 110 | 5.4 | 24 |

| 22a | 220 | 120 | 5.4 | 25.8 |

| 24 | 240 | 115 | 5.6 | 27.3 |

| 24a | 240 | 125 | 5.6 | 29.4 |

| 27 | 270 | 125 | 6 | 31.5 |

| 27a | 270 | 135 | 6 | 33.9 |

| 30 | 300 | 135 | 6.5 | 36.5 |

| 30h | 300 | 145 | 6.5 | 39.2 |

| 33 | 330 | 140 | 7 | 42.2 |

| 36 | 360 | 145 | 7.5 | 48.6 |

| 40 | 400 | 155 | 8 | 56.1 |

| 45 | 450 | 160 | 8.6 | 65.2 |

| 50 | 500 | 170 | 9.5 | 76.8 |

| 55 | 550 | 180 | 10.3 | 89.8 |

| 60 | 600 | 190 | 11.1 | 104 |

| 65 | 650 | 200 | 12 | 120 |

| 70 | 700 | 210 | 13 | 138 |

| 70a | 700 | 210 | 15 | 158 |

| 70b | 700 | 210 | 17.5 | 184 |

I Beam Weight Calculator

However, it is important to note that there may be a certain degree of discrepancy between the theoretical weight and the actual weight. The theoretical weight provided by our calculator may differ from the actual weight, with a margin of error of approximately 0.2% to 0.7%. Therefore, when making precise calculations or transactions, it is best to adjust the results based on the actual situation.

What are the differences in theoretical weight of I-beams made of different materials (such as Q235, Q345, etc.)?

The theoretical weight of I-beams made of different materials (such as Q235, Q345, etc.) varies, mainly due to different alloy contents. Q235 is common carbon steel while Q345 is low alloy steel. This means that Q345 contains more alloying elements than Q235, which can increase the strength, toughness and other properties of steel.

Therefore, due to the difference in alloy content, the theoretical weight of Q345 is generally heavier than that of Q235.

For the calculation formula, the theoretical weight of the I-beam can be calculated using the formula W = 0.00785 (hd +2t (bd) +0.615 (r 2 r1 2 )) where W represents the theoretical weight (in kg/m ), h is the height, b is the length of the leg, d is the thickness of the waist, t is the average thickness of the leg, r is the radius of the inner arc and r1 is the final radius of the arc.

This formula applies to I-beams of different materials, but in actual calculations, the density value will vary due to the difference in material. For example, the density of low carbon steel (such as Q235) is calculated as 7.85g/cm 3 while the density of stainless steel may be slightly lower.

The difference in theoretical weight of I-beams made of different materials is mainly due to their different alloy contents. Although the theoretical specific weight needs to be determined according to the specific dimensions and material characteristics of the I-beam through the calculation formula, generally speaking, the theoretical weight of low alloy steel (such as Q345) will be heavier than that of common carbon steel. (like Q235).

How to choose the right specification and model of I beam according to different application scenarios such as construction and mechanical manufacturing?

Choosing the appropriate I-beam size and model requires understanding the basic parameters and application scenarios of the I-beam. I-beam specifications can be represented by its height/depth (h), width (b), and weight or mass (w). In addition, the I-beam model can also be represented by the number of centimeters in waist height, for example, I16# represents an I-beam with a waist height of 160mm.

In different application scenarios such as construction and mechanical manufacturing, the selection of I-beams also needs to consider their mechanical properties and size range. For example, the weight of 18# national standard I beam should be between 39.2-79.5kg/m with a size range of 100-400mm, suitable for scenarios that require greater load capacity and a certain length. European standard I-beam model standards are mainly differentiated based on their cross-sectional sizes and belly plate heights, with common models including IPE80, IPE100, etc., suitable for scenarios with specific shape and size requirements.

For cantilever structures, the selection of I-beams also needs to consider thickness, as it has a direct impact on the stability and safety of the cantilever structure. Furthermore, the selection of I-beams must comply with relevant national standards and regulations to ensure their safe and reliable performance.

When choosing the appropriate I-beam size and model, it is essential to take into consideration the specific application scenario, the required load capacity, the stability of the structure, as well as the relevant standards and regulations to be complied with. For example, in building structures, it may be necessary to choose I-beams with greater bearing capacity and specific size range, while in areas such as mechanical manufacturing, the shape and size of the I-beam to meet specific project requirements may be more emphasized.

The Difference Between Standard and Lightweight I-Beams

Standard I-beams are processed from common steel, while lightweight I-beams are made from lightweight alloys such as aluminum and magnesium. When compared to standard I-beams, lightweight I-beams have wider flanges and thinner webs and flanges. Given the same depth, lightweight I-beams offer better stability, ensuring the same load capacity, saving metal and providing better economic efficiency.

Regardless of whether they are standard or lightweight, I-beams tend to have relatively high and narrow cross-sectional dimensions, resulting in a significant difference in the moment of inertia about the two main axes.

Therefore, they are typically used directly for members subject to bending within their soul plane or as part of a truss strength member. When used individually, they can only serve as general bending elements and eccentric compression elements, such as secondary beams or eccentric pillars on work platforms.

However, when used as mixed sections, they can function as main compression elements.

I-beams come in standard and lightweight varieties.

Compared to the same standard I-beam model, lightweight I-beams have smaller thickness and lighter weight. Flange width varies by model size: smaller models (I32# and below) have narrower flange widths than standard I-beams, while larger models (I40# and above) have wider flange widths.

1comment

Bom dia! Construir uma ponte para tráfego leve – até dois mil quilos.

Os vãos são 8.3 metros / 8.3 / 6 / 5 / 5.5

Qual tipo de viga I eu preciso? Obrigado