If you intend to accurately calculate the weight of various steel materials, you need to be aware of their respective densities such as steel, iron, aluminum, brass, etc.

This information can then be used to calculate the weight of various steel products such as MS sheet, GI sheet, carbon steel, stainless steel, MS angle, MS pipe, etc. using the weight calculation formula in kilograms per meter cubic (kg/ l 3 ).

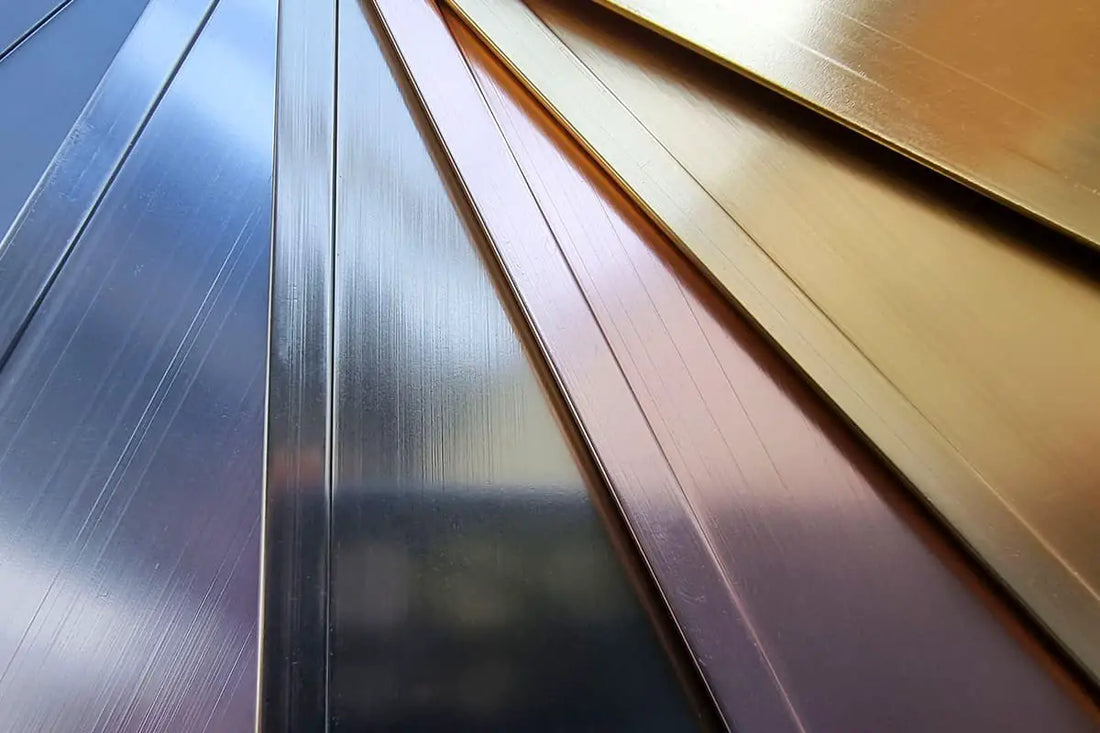

Sheet Metal Density Chart

Below is the density table of various sheet metal materials.

| Item | Note | Density | |

| (g/mm³) | (kg/m³) | ||

| aluminum plate | A1100 | 0.00272 | 2720 |

| Aluminum Foil | 0.00272 | 2720 | |

| aluminum alloy | A5052-H32 | 0.00272 | 2720 |

| Brass sheet (hard) | C2680R | 0.0085 | 8,500 |

| Brass sheet (soft) | C2680R | 0.0085 | 8,500 |

| PH.Bronze | C5191 | 0.00878 | 8780 |

| Pure Copper | C1100 | 0.009 | 9,000 |

| Beryllium Copper | C1720-1/2H | 0.0083 | 8300 |

| Stainless steel (hard) | SUS 304 | 0.0078 | 7800 |

| Stainless steel | AISI 430 | 0.0078 | 7800 |

| Stainless steel | SUS 301 | 0.0078 | 7800 |

| Stainless steel (soft) | SUS 304 | 0.0078 | 7800 |

| Secc/Electrogalvanized Steel | T1/T2/EW/EL | 0.0078 | 7800 |

| PVC Laminated Steel Sheet | 99033 | 0.00645 | 6450 |

| 99033-3 (Black) Anti-Finger Coating | 99033-3 (Korea) | 0.00645 | 6450 |

| C010R: B200 | 0.00645 | 6450 | |

| ZINC PLATE/Galvanized Steel | JIS G3303 SGCC | 0.00803 | 8030 |

| CR steel | 0.00785 | 7850 | |

| Black Steel | 0.0077 | 7700 | |

| SPCC/Cold rolled steel | JIS G3141 SPCC-SD | 0.0078 | 7800 |

| Cold rolled steel - 1/4 hard | JIS G3141 SPCC-4B | 0.0078 | 7800 |

| Cold-rolled hard steel | JIS G3141 SPCC-1B | 0.0078 | 7800 |

| Cold rolled steel mesh | 0.0078 | 7800 | |

| tin plate | JIS G3303 | 0.0079 | 7900 |

| Tinplate Lining 2.8/2.8 | JIS G3303 | 0.0079 | 7900 |

| Silicon Steel | (without direction) | 0.00738 | 7380 |

| Silicon Steel – Zll | (with direction) | 0.00738 | 7380 |

What is the specific density of aluminum and aluminum alloys?

The specific density of aluminum and aluminum alloys varies widely as they can be composed of different elements, including, among others, aluminum, copper, magnesium, manganese and silicon. The density of pure aluminum is approximately 2.7g/cm³, while the density of aluminum alloys varies depending on the components of the alloy.

For example, the density of 6061 aluminum alloy is 2.75g/cm³, and the densities of other aluminum alloys can be 2.72, 2.73 or 2.82g/cm³.

Additionally, there are other types of aluminum alloys, such as the LF and LY series, with densities ranging from 2.64 to 2.73g/cm³.

The density of aluminum and aluminum alloys is not a fixed value, but varies depending on the composition and specific type of alloy. The density of pure aluminum is approximately 2.7g/cm³, while the density of aluminum alloys can vary from 2.64g/cm³ to 2.82g/cm³, depending on the type and composition of the alloy.

What is the difference in density between stainless steel and other types of stainless steel (such as 304, 316)?

The main distinction in density between stainless steel and other types like 304 and 316 lies in their specific numbers. The density of 304 stainless steel is approximately 7.93g/cm³, while the density of 316 stainless steel is slightly higher, around 8.03g/cm³.

This indicates that although both are types of stainless steel with similar physical and chemical properties, such as acid and alkali resistance, ease of processing and high toughness, there are slight differences in their density.

This variation may be related to its composition, for example, 316 stainless steel may contain more alloying elements such as molybdenum (Mo), which may result in its density being slightly higher than that of 304 stainless steel.

Furthermore, from a broader perspective, the density of most stainless steel materials generally fluctuates between 7.70-8.00g/cm³, further confirming that the difference in density between 304 and 316 stainless steel is relatively small.

Therefore, despite the very similar applications and performance of 304 and 316 stainless steels, their densities are slightly different, likely due to subtle differences in their composition.

How does the density of soft brass sheets compare to other brass materials such as hard brass and bronze?

The density of soft brass sheet varies approximately between 8.50 and 8.80 *10 3 kg/m 3 . In contrast, the density of hard brass is not directly mentioned, but it can be inferred that its density may be similar or slightly different from that of common brass. Hard brass typically refers to an alloy with a higher proportion of copper and zinc, which can affect its density. The density of bronze, on the other hand, is between 7,400 and 8,900 kilograms per cubic meter.

From these data, it is evident that the density of soft brass sheet is slightly lower than that of bronze, but higher than that of copper (8.9 ~ 8.95 g/cm 3 or 8.9 ~ 8.95*10 3 kg/ m3 ). This implies that although soft brass sheet is not the lightest material, it still performs well, especially demonstrating wear resistance in applications such as machine bearing linings, valves and pipe fittings.

Compared to other brass materials such as hard brass and bronze, the density of soft brass sheet is slightly lower but still moderate, making it an ideal choice for a variety of industrial applications.

What is the density of beryllium copper and how does it compare to pure copper and beryllium in terms of characteristics?

The density of beryllium copper varies between 8.2g/cm³ and 8.75g/cm³, with specific values varying depending on the product and manufacturer. For example, some sources quote a standard density of 8.6g/cm³, while some manufacturers produce it with a density of 8.4g/cm³.

On the other hand, the density of beryllium copper alloys such as C17500 is 8.75g/cm³ before age hardening, and high-performance beryllium copper has a density of 8.3g/cm³. These numbers suggest that the density of beryllium copper can vary based on its specific chemical composition, manufacturing process, and whether it undergoes anti-aging treatment.

Compared to pure copper, beryllium copper has a variety of unique characteristics. First, beryllium copper is a precipitation hardening alloy which, after solution aging treatment, can significantly increase its strength, hardness, elastic limit and fatigue limit, maintaining minimum elastic hysteresis and providing good corrosion resistance, toughness wear resistance, resistance to low temperatures and non-magnetism.

Furthermore, beryllium copper has high electrical and thermal conductivity, making it extremely useful in applications that require good electrical or thermal performance. Lastly, due to its relatively high density, beryllium copper can offer superior mechanical and processing performance in certain applications.

With a density ranging from 8.2g/cm³ to 8.75g/cm³, beryllium copper presents a series of excellent physical, chemical and mechanical properties compared to pure copper, such as high strength, high hardness, good corrosion resistance and wear resistance. These characteristics make it highly sought after in various industrial applications.

Common questions

What is the density of carbon steel (ms)?

The density of ms is 7.85g/cm 3 or 7,850kg/m 3

What is the density of galvanized steel (gi)?

The density of galvanized steel is 7.85g/cm 3 for Secc/Electrogalvanized Steel and 8.03g/cm 3 for ZINC PLATE/Galvanized Steel

What is the density of aluminum foil?

The density of aluminum foil is 2.72g/cm 3 or 2720kg/m 3