1. What is the function of a bus? What types are commonly used?

The bus is used to connect voltage distribution devices at various levels of the substation, as well as to connect electrical equipment such as transformers and respective distribution devices.

Typically it is a bare or stranded wire with a rectangular or circular cross section. The function of a bus is to collect, distribute and transmit electrical energy.

Since a large amount of electrical energy passes through the bus during operation, it experiences significant heating and electromagnetic effects during short circuits.

Therefore, it is essential to properly select the busbar material, cross-sectional shape and area to meet the requirements for safe and economical operation.

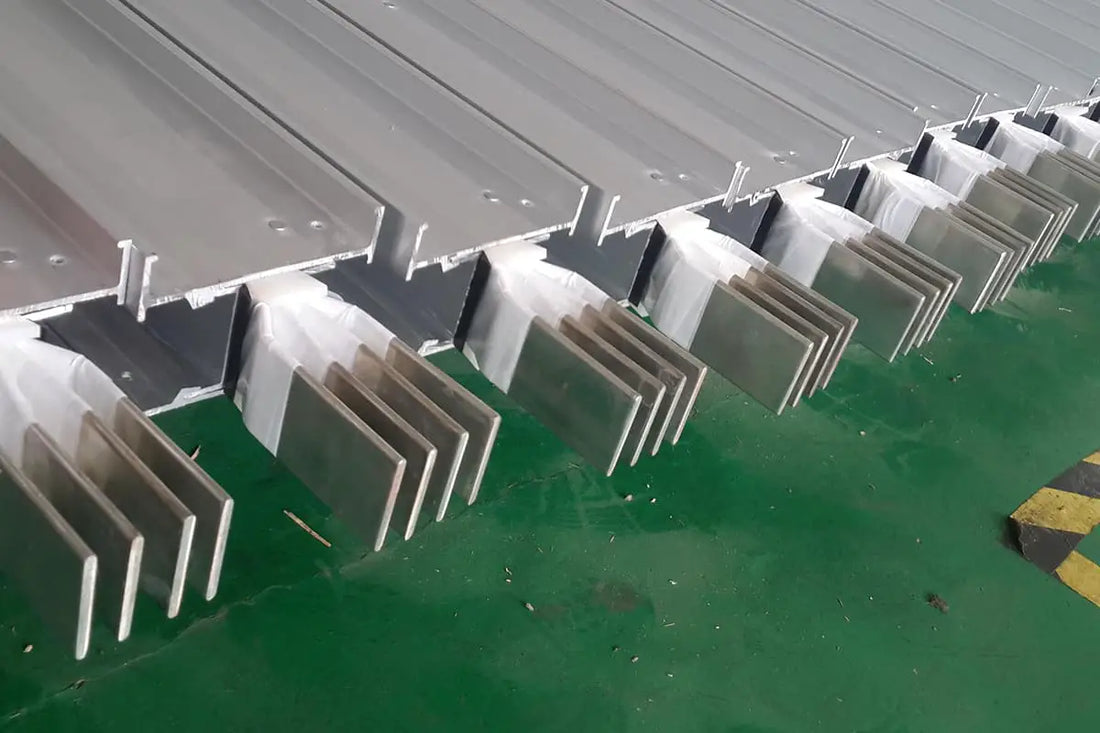

Busbars are categorized by structure into rigid and flexible buses. Rigid buses are divided into rectangular and tubular buses.

Rectangular busbars are generally used from the main transformer to the power distribution room. They are advantageous due to their easy installation, minimal operational changes and large current carrying capacity, but they tend to be more expensive.

Soft buses are used outdoors where large spaces ensure that wire swinging does not result in insufficient line spacing. Flexible busbars are easy to install and relatively inexpensive.

In recent years, for busbars above 35kV in substation projects, tubular busbars made of aluminum alloy materials are used.

This type of bus structure can reduce the distance between buses, provide clear wiring and reduce maintenance, but the bus fixing hardware is somewhat complex.

2. Why is it necessary to install an expansion compensation device for rigid busbars?

When current passes through the bus, it generates heat. The amount of heat is directly proportional to the square of the current passing through the bus. Thermal expansion and contraction of the rigid busbar can cause dangerous stresses on the busbar insulator. Installing a bus compensator can effectively mitigate this stress.

The compensator can be made of 0.2 to 0.5 mm copper or aluminum sheets (for aluminum busbars), and its total cross-section should not be less than 1.2 times that of the original busbar.

The compensator must not have cracks, bends or fragments, and the oxide layer must be removed between each piece. Aluminum sheets must be coated with neutral petroleum jelly or compound grease, and copper sheets must be tinned.

3. What measures should be taken to prevent the formation of eddy currents in the busbar support porcelain insulator clamp?

If the bus clamp is made of ferrous material, it will form a closed magnetic circuit. Under the action of alternating current, an induced current, or eddy current, will be generated in the closed circuit, causing localized heating of the bus and increasing energy loss.

The greater the current on the bus, the more severe the effect. Therefore, the bus clamp must not form a closed magnetic circuit.

4. To avoid the generation of eddy currents, what measures should be taken?

The following measures must be adopted in the busbar fixing clamps:

1) One of the two clamps can be made of iron, while the other is made of aluminum or copper.

2) When both clamps are made of iron, one of the two fixing screws must be made of iron and the other must be made of copper.

3) Iron materials can be used to make open clamps to fix the busbar.

5. What overvoltage protection measures are generally adopted for high voltage overhead lines?

Given the length of overhead lines and their distribution across different regions, lightning accidents are relatively common (representing more than 90% of lightning accidents on the power grid).

Therefore, strict and comprehensive overvoltage protection measures must be taken for high-voltage overhead lines, mainly including the following:

1) Direct measures to prevent atmospheric discharges, such as installing lightning rods, using lightning rods in some areas and using protective gaps.

2) Protection against backflashovers: When the top of a pole or lightning rod is struck by lightning, due to the pole tower inductance and grounding resistance, the lightning current can cause the pole tower potential to reach a value that causes a backflashover on the line.

Commonly, measures such as reducing grounding resistance, reinforcing insulation and increasing the coupling coefficient can be adopted for protection.

3) Protection against the occurrence of steady-state power frequency arcs: After the line insulation undergoes an impulse flashover, as long as a short-circuit arc does not occur at constant power frequency, the line will not trip.

Therefore, measures such as reducing the potential gradient in insulation, ungrounded neutral or grounding through an arc suppression coil must be employed, so that the majority of impulse discharge arcs disappear on their own, without causing a short circuit at the frequency of power.

4) Protection against interruption of power supply, such as implementing automatic reclosing as a corrective protection measure.

6. What are the requirements for lightning protection in 10kV line pole circuit breakers?

Lightning protection requirements for 10kV line pole circuit breakers are as follows:

(1) Metal oxide arresters, valve-type arresters, tube-type arresters or protective gaps must be installed for protection.

(2) For pole-mounted circuit breakers that are frequently turned off but remain energized, arresters must be installed on the energized side. The ground wire must be connected to the metal case of the pole-mounted circuit breaker and the ground resistance must not exceed 10Ω.

(3) For frequently closed circuit breakers, surge arresters should only be installed on the power supply side; For interconnecting line circuit breakers that are frequently turned off, lightning arresters must be installed on both sides of the circuit breaker.

(4) Lightning arresters must be installed as close as possible to the protected circuit breaker.

7. Why are overhead earth wires generally not installed on distribution lines below 10kV?

The insulation resistance of distribution lines below 10kV is generally not high.

If overhead grounding wires are installed on these lines and lightning strikes the wires, it can easily initiate a “blowback” to the distribution line from its grounding cable, not only failing to provide lightning protection, but also causing lightning damage.

Additionally, the cost of installing overhead ground wires is substantial, which is why they are generally not installed on distribution lines.