Additive manufacturing technology has long been recognized for its powerful capabilities and has been widely used in various industries, including marine, aerospace and automotive.

Notably, it is increasingly adopted by defense departments around the world. In fact, by 2027, the military 3D printing industry is expected to be worth $1.7 billion.

Given the military's demand for faster speeds, lighter weights and lower costs, selecting additive manufacturing technology to achieve these characteristics is undoubtedly the most appropriate choice.

This article lists some cases of 3D printing technology used in the defense sectors of different countries. From these practical examples, we can further appreciate the importance of this technology in defense.

1. 9 meter long metal 3D printer

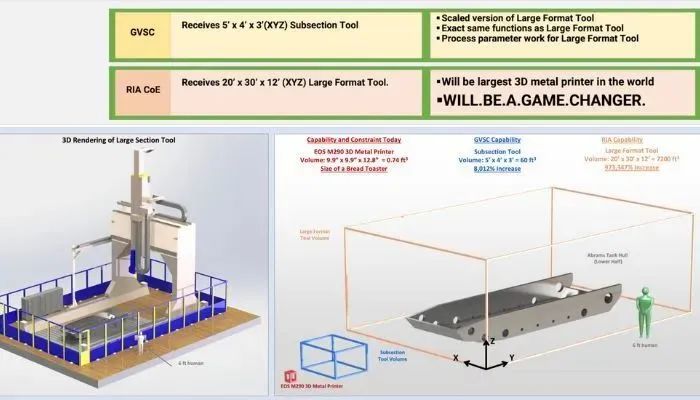

The US military is fully convinced of the benefits of additive production. In 2021, they announced plans to build the world's largest metal 3D printer. Army Land Vehicle Systems Center DEVCOM is building this colossal printer with help from ASTRO America, Ingersoll Machine Tools, Siemens and the MELD Manufacturing collaboration at the Rock Island Arsenal. This printer will become part of the Seamless Hull project, with the ultimate goal of printing an integrated hull for combat vehicles.

It is reported that the project will take approximately 14 months to complete. Upon completion, the printer will be capable of printing metal parts measuring 30 feet long, 20 feet wide and 12 feet high (approximately 9 meters by 6 meters by 3.6 meters).

2. 3D printed tracks

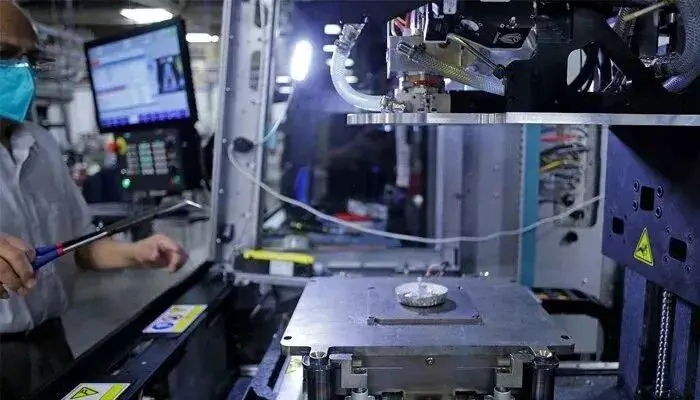

Another application in the military and defense sector comes from ITAMCO (Indiana Technology and Manufacturing Companies), which is using additive manufacturing to develop a runway for military expeditionary airfields. These runway mats are essential components of Expeditionary Airfields (EAFs).

Its objective is to be put into action on weaker terrain, allowing military aircraft to land and take off. Previously, portable tracks made from aluminum sheets were used, but as these became obsolete, the military needed to find an innovative solution.

German company EOS's M290 3D printer has been employed to manufacture lighter, more durable models for US Air Force military equipment.

3. ExOne and its military container

In an attempt to accelerate the development of robust 3D-printed factory containers, ExOne became involved in this effort following collaborations with several partners. Specifically, it involves a $1.6 million contract with the Defense Logistics Agency (DLA).

Throughout this process, ExOne's Binderjet technology, known for its speed, material flexibility and ease of operation, has been used for military purposes, effectively meeting the military's critical needs.

This 3D printer, designed specifically for the military, is said to be capable of releasing adhesive, dispensing more than 20 types of metals, ceramics and other powdered materials. Additionally, its unique casing and other features make it exceptionally suitable for military-grade products.

4. US Navy 3D Printed Tools

The US Navy is also harnessing the power of additive manufacturing. The Marine Corps has discovered the potential of 3D printing in developing new vehicle maintenance tools.

In collaboration with supply fields and industry partners, Marine Corps Systems Command has produced an additive manufacturing clamp through 3D printing technology. This clamp is designed to separate metal flywheels – a common problem in marine vehicle maintenance.

Additive manufacturing helps reduce maintenance and tooling preparation time, successfully decreasing the actual lead time for these parts to around 25 days.

5. The US Army and the University of South Florida develop lightweight magnesium alloy

In the field of 3D printing technology, the US Army regularly collaborates not only with relevant companies but also with several universities. Recently, scientists at the University of South Florida successfully 3D printed a magnesium alloy known as WE43.

The development of this material was not accidental, but rather motivated by military needs. US soldiers are often burdened with extremely heavy backpacks and equipment, so research into reducing their burden is of paramount importance.

However, with the help of WE43 and the powder bed fusion process, the US Army and the University of South Florida may have discovered a solution.

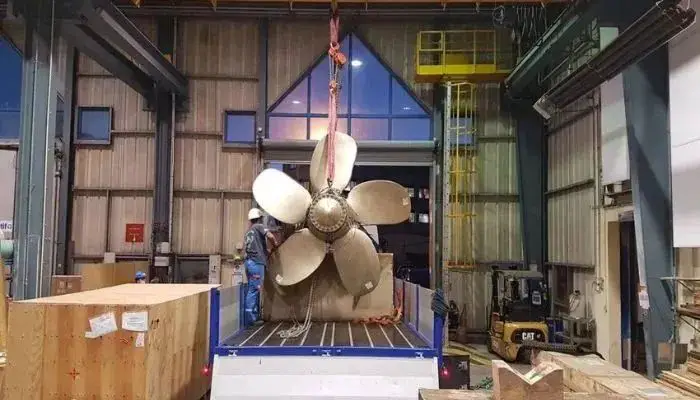

6. 3D Printed Propeller for Ships

In recent years, renowned French company Naval Group has been employing 3D printing technology to satisfy a variety of needs. In January 2021, thanks to the Wire Arc Additive Manufacturing (WAAM) process, Naval Group successfully 3D printed a propeller.

Composed of five blades, each weighing 200 kg, the propeller was then installed on the Perseus, a minesweeper ship. The team behind this project revealed that by using 3D printing technology, they significantly reduced construction time and minimized the amount of material used.

7. The Spanish Air Force updates its processes through 3D printing

Additive manufacturing can help parts achieve high hardness, strength and other exceptional attributes. Through internal fiber reinforcement, researchers have developed a variety of tools and end parts that can withstand the rigorous performance conditions required in high part stress situations, without any margin for error.

In Madrid, the head of the Spanish Air Force's helicopter workshop stated that they are now trying to manufacture each part through additive production, avoiding traditional production methods. These parts include leak control measurement tools for helicopter landing gear and custom wrenches for helicopter main rotors.

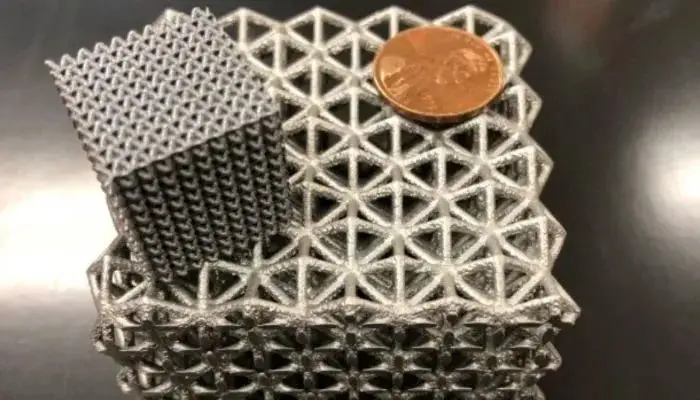

8. General Lattice and his helmet design for the US Army

General Lattice, a 3D design software company, has signed a contract with the US Army to improve the impact absorption capabilities of combat helmets through 3D printing and advanced lattice geometries. For this project, the company developed a set of predictive modeling tools to design and generate materials for helmets.

To enhance soldiers' protection on the battlefield and increase their likelihood of survival after head impacts, 3D printed materials will be tested in real-world conditions to validate performance requirements defined by the Command Soldier Center.

9. Spare parts in armored combat vehicles

The Australian Army has designed dozens of replacement parts for one of its armored vehicles using a cold spray 3D printing solution developed by SPEE3D. These components have undergone multiple field use tests and certifications, increasing the Australian Army's agility.

For example, the printed parts include a hubcap produced in just 29 minutes, with a total cost of 100 Australian dollars. By introducing additive manufacturing technology, the military is able to reduce the downtime of armored vehicles, thus dealing more effectively with emergencies.

10. The US Navy and Additive Manufacturing

For several years, the US Navy has been carrying out numerous additive manufacturing projects. The objective is to increase the agility and efficiency of teams that carry out missions in the open sea, mainly in the manufacture of spare parts. That's why the Naval Postgraduate School (NPS) invested in the Xerox ElemX metal machine.

They use this equipment to design replacement parts and tools for submarines and ships, allowing Xerox to have a shorter supply chain and manufacture custom components. However, NPS is not the only organization launching 3D printing initiatives in the maritime sector.

In fact, MatterHackers signed a five-year contract with the US Navy to provide all necessary 3D equipment, along with training and maintenance courses.

11. Future Energy Project

The UK's Future Energy Project is involved in research, explosives testing, new energy manufacturing, explosives modeling, chemical synthesis, thermal characterization and hazard testing.

The project aims to create new energetic materials and diagnostic methods to verify these new materials. Additive manufacturing will be employed to develop new explosive formulations, offering numerous advantages to potential users, such as reduced storage and transportation costs and improved performance.

Costs can be precisely adapted according to requirements and manufactured into innovative and complex designs, a previously unimaginable concept. The manufacturing process uses the LabRAM Resonant Acoustic Mixer, which uses acoustic energy instead of physical blades to mix the materials, making the process safer.

12. ASTRO America develops 3D-printed armored vehicle hulls

The applied science and technology research organization, also known as ASTRO America, was selected by the U.S. Army for the continuous hull design.

Supported by the Manufacturing Innovation Institutes, which benefit from the US Department of Defense, this plan is part of an effort to develop and deliver armored vehicle hulls using 3D printing.

Their aim is to reduce manufacturing time and production costs, while lightening the weight of vehicles and improving their performance and survivability.

13. 3D printed military barracks

ICON, a 3D construction company known for its involvement in military projects, collaborated with the Texas Military Department, Logan Architecture and Fort Structures to create the largest 3D printed structure in North America.

The training camp, located at the Swifte Camp Training Center in Bastrop, Texas, was built using ICON's Vulcan construction system – a tablet-operated robotic printer capable of using cement-based materials.

This successful partnership between the company and the military resulted in the first 3D printed military barracks for soldiers to live in. The final structure consists of a 3,800 square meter building, with the capacity to house up to 72 soldiers or pilots, preparing them for their next assignments.

14. 3D printing of submarine hulls

For years, the Department of Defense has found ways to apply 3D printing in multiple domains – on land, in the air and at sea. In fact, one of the U.S. military's latest projects delves into relatively unknown 3D printing territory: underwater.

In a pioneering effort in 2017, Oak Ridge National Laboratory (ORNL) collaborated with the U.S. Navy's Disruptive Technology Laboratory, resulting in the first 3D-printed submarine hull in military history.

Using ORNL's Fused Deposition Modeling Large Area Additive Manufacturing (FDM BAAM) technology, the team created a 30-foot conceptual hull comprised of six carbon fiber composite sections, demonstrating faster production and lower costs compared to traditional production methods. manufacturing.

Although they are still being tested, indicators suggest that we will soon witness more 3D printed submarines diving into the oceans.

15. The University of Maine develops logistics support ships for the US Marine Corps

In March of this year, the University of Maine (UMaine), at its Advanced Structures and Composites Center in Orono, 3D printed two large ships, one of which is reportedly the largest additively manufactured ship in history.

These prototype ships were developed for the US Marine Corps, designed as logistics support ships, and will undergo testing for active military use. The larger of the two can hold two 20-foot containers, while the other can carry three days' worth of food, water and other supplies for an entire rifle squad.

Both new containers were 3D printed from a multi-material blend based on polymeric fiber-reinforced composites. According to UMaine, they were able to manufacture and assemble one of these vessels in just one month – a process that would have taken up to a year using traditional manufacturing methods.