Almost half of the world's energy consumption is attributed to engines, making the efficient use of engines one of the most effective measures to solve global energy problems.

A motor is a device that converts electrical energy into mechanical energy. It uses a powered coil (the stator winding) to generate a rotating magnetic field, which acts on the rotor (like an enclosed squirrel cage aluminum structure) to create a rotating magnetic torque.

Motors are divided into direct current (DC) motors and alternating current (AC) motors based on the type of power source used. Most power system motors are AC motors, which can be synchronous or asynchronous (the rotational speed of the motor's stator magnetic field is not synchronized with the rotational speed of the rotor).

A motor mainly consists of a stator and a rotor. The direction of movement of the energized conductor in the magnetic field is related to the direction of the current and the direction of the magnetic field lines. The working principle of a motor is the force of the magnetic field on the current, causing the motor to rotate.

Engine control refers to controlling the starting, acceleration, operation, deceleration and stopping of the engine. There are different requirements and objectives depending on the type of engine and the circumstances in which the engine is used. For motors, through motor control, the objectives of fast starting, fast response, high efficiency, high torque output and high overload capacity are achieved.

The standard motors, servo motors, stepper motors and servo motors mentioned here refer to DC micromotors, which we encounter frequently. A motor, also known as a “motor”, refers to this electromagnetic induction device that maintains the transformation or transmission of electromagnetic energy in accordance with Faraday's law of electromagnetic induction.

A motor, also known as an “electrical machine”, is represented in the power circuit by the English letter “M” (previously represented by “D”). Its main function is to generate drive torque as a source of energy for electrical devices or various machines. A generator is represented by the letter “G” in the circuit.

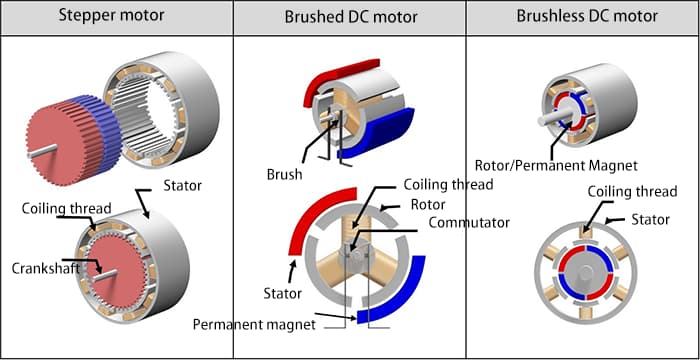

1. Types of engines

Generally, motors refer to devices that convert the force generated by the flow of electrical current in a magnetic field into rotational motion and, in a broader sense, also into linear motion.

Motors can be classified into two categories based on their power source: DC motors and AC motors.

They can also be categorized based on their rotation principles, with some exceptions for special types of engines.

(1) DC motor

Brushed motor

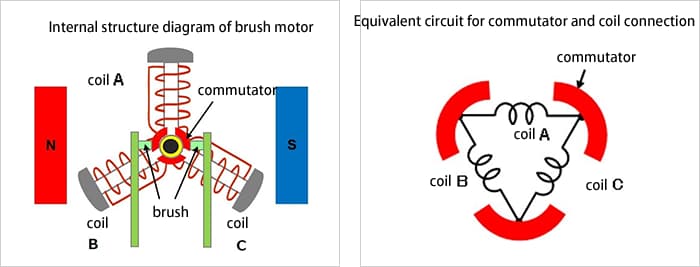

The widely used brushed motor is generally referred to as DC motor. The rotor rotates by switching the current through electrodes called “brushes” (on the stator side) and a “commutator” (on the armature side).

Brushless DC Motor

This motor does not require brushes or a commutator, but instead uses switching functions such as transistors to switch currents and rotate the motor.

stepper motor

This motor operates synchronously with the pulse power and hence it is also called pulse motor. Its feature is easy and accurate positioning operation.

(2) AC Motor

asynchronous motor

Alternating current causes the stator to produce a rotating magnetic field, which causes the rotor to produce an induced current and rotate under its interaction.

Synchronous motor

AC creates a rotating magnetic field and the rotor with the magnetic field rotates due to the attraction. The rotation rate is synchronized with the power frequency.

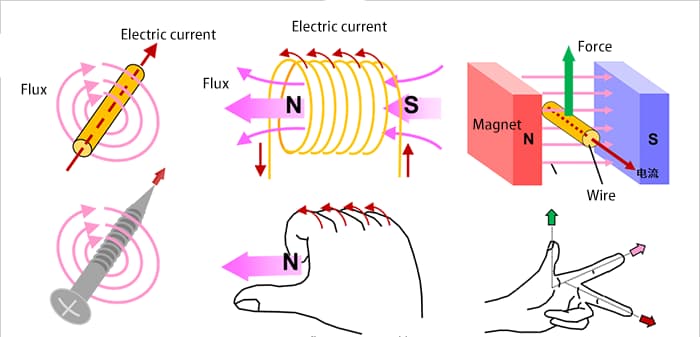

About electric current, magnetic fields and force

First, to facilitate the explanation of motor principles, let's review the basic laws of electric current, magnetic fields and force. Although it may bring a feeling of nostalgia, it is easy to forget this knowledge if we do not use magnetic components frequently.

We will use images and formulas to illustrate this.

When the wire loop is a rectangle, we need to consider the force acting on the current.

The force F acting on sides a and c can be calculated by the following formula:

This produces a torque around the central axis.

For example, when considering the state where the angle of rotation is just θ, the force acting on bed at right angles is sinθ. Therefore, the torque Ta on side a can be expressed by the following formula:

Likewise, considering side c, the torque doubles and generates a torque calculated by the following formula:

Since the area of the rectangle is S = hxl, substituting it into the above formula produces the following results:

This formula not only applies to rectangles but also other common shapes like circles. Engines use this principle.

Standard engine

A standard motor, often seen in everyday items such as electric toys and electric shavers, is typically a brushed DC motor. Characterized by high speed and low torque, it requires only two pins to operate. When connected to the positive and negative terminals of a battery, the motor starts to rotate. Reversing the connection will cause the motor to rotate in the opposite direction.

Gear reduction motor

A gear reduction motor is a standard motor equipped with a gearbox. This design reduces rotational speed while increasing torque, expanding the range of practical applications for the standard motor.

servo motor

A servo motor mainly consists of a housing, circuit board, coreless motor, gears and position detector. It operates by receiving a signal from the receiver to the servo motor. The integrated IC determines the rotation direction and drives the coreless motor to start rotating.

Motion is transmitted to the swing arm via reduction gears and the position detector simultaneously sends signals back to check whether the desired position has been reached. The position detector is essentially a variable resistor, which changes resistance values as the servo motor rotates. By detecting these resistance values, the rotation angle can be determined.

Specifications provided by servomotor manufacturers generally include dimensions (mm), torque (kg/cm), speed (sec/60°), test voltage (V), and weight (g). The unit of torque is kg/cm, indicating how many kilograms can be lifted with a 1 cm long swing arm.

This is the lever arm concept, so the longer the arm, the lower the torque. The speed unit is sec/60°, representing the time required for the servo motor to rotate 60°.

stepper motor

A stepper motor is an open-loop control element that converts electrical pulse signals into angular or linear displacement. Under non-overload conditions, the speed and stopping position of the motor depend solely on the frequency and number of pulse signals, regardless of load changes.

When a stepper driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle, known as the “step angle,” in a predetermined direction. Its rotation progresses in fixed-angle increments. The number of pulses can be controlled to manage angular displacement, achieving precise positioning. Likewise, the pulse frequency can be used to control the rotational speed and acceleration of the motor, thus achieving speed regulation.

A servo motor, also known as an actuator motor, serves as the executing unit in automatic control systems by converting incoming electrical signals into an angular displacement or angular velocity output on the motor shaft.

It comes in two main categories: direct current (DC) and alternating current (AC) servo motors. The main feature of these motors is that there is no autorotation phenomenon when the signal voltage is zero, and the rotation speed decreases uniformly as the torque increases.

Servo motors mainly rely on pulses for positioning. Essentially, the servo motor rotates at an angle corresponding to the pulse for each pulse received, thus achieving displacement. As the servo motor itself has the ability to emit pulses, it emits a corresponding number of pulses for each degree of rotation.

This forms a responsive or 'closed loop' system with the received pulses. This way, the system knows how many pulses were sent to the servo motor and how many pulses were received back. Consequently, it can control the engine rotation very precisely, allowing precise positioning down to 0.001 mm.

Servo motors are broadly divided into AC servo and DC servo categories.

AC servo motors are divided into asynchronous AC servo motors and synchronous AC servo motors.

DC servo motors are divided into brushed and brushless motors. Brushed motors are low cost, simple in structure, produce high starting torque, have a wide speed control range and are easy to control. They require maintenance but are inconvenient (e.g. brush replacement), produce electromagnetic interference and have specific environmental requirements. Therefore, they are suitable for cost-sensitive general industrial and civil applications.

2. How do engines rotate?

1) Motors rotate with the help of magnets and magnetic force

Around a permanent magnet with a rotating axis,

- ① Rotate the magnet (to produce a rotating magnetic field),

- ② According to the principle of opposite poles attract and like poles repel between N pole and S pole,

- ③ The magnet with the rotating shaft will rotate.

This is the basic principle of engine rotation.

Current flow through a wire generates a rotating magnetic field (magnetic force) around it, which causes the magnet to rotate.

In fact, this is the same operating state as described previously.

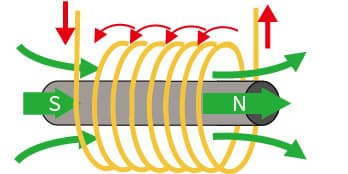

Furthermore, if the wire is wound into a coil, the magnetic forces are combined to form a large magnetic field flux (magnetic flux), which produces N and S poles.

Inserting an iron core into the wire in the form of a coil facilitates the passage of magnetic field lines and generates a stronger magnetic force.

2)Practical rotary motors

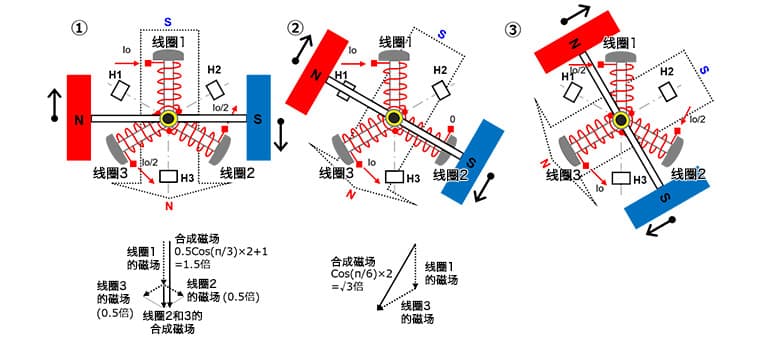

Here we will introduce the practical method of using three-phase AC and coils to produce a rotating magnetic field like a rotary motor.

(Three-phase AC is an AC signal with a phase difference of 120°.)

The combined magnetic field in the above state ① corresponds to figure ① below.

The combined magnetic field in state ② above corresponds to figure ② below.

The combined magnetic field in the above state ③ corresponds to figure ③ below.

As mentioned above, the coil wound around the iron core is divided into three phases, with the U phase coil, V phase coil and W phase coil arranged at 120° intervals.

The coil with high voltage generates an N pole, while the coil with low voltage generates an S pole.

Each phase changes according to a sine wave, so the polarity (N pole, S pole) and magnetic field (magnetic force) of each coil will change.

At this time, if we look at the coil that produces an N pole, it changes sequentially from the U phase coil to the V phase coil, from the W phase coil to the U phase coil, causing rotation.

3. Structure of Small Engines

The following figure shows the approximate structures and comparisons of three types of motors: the stepper motor, the brushed DC motor, and the brushless DC motor.

The basic components of these motors are mainly coils, magnets and rotors, and they are classified as coil-fixed type and magnet-fixed type due to their different types.

The following is a structural explanation related to the example diagram. Since there may be other structures if we break them down further, please understand that this article describes the general structure.

In the stepper motor shown here, the coil is fixed on the outer side and the magnet rotates on the inner side.

In the brushed DC motor shown here, the magnet is fixed on the outer side and the coil rotates on the inner side. The brushes and commutator are responsible for supplying energy to the coil and changing the direction of the current.

In the brushless motor shown here, the coil is fixed on the outer side and the magnet rotates on the inner side.

Due to different types of engine, even if the basic components are the same, the structure may be different. Detailed explanation will be given in each section.

4. Brushed Motor

Brushed Motor Structure

Shown below is what a brushed DC motor often used in models looks like, as well as an exploded diagram of a typical two-pole (2 magnets) and three-slot (3 coils) motor. Many people may have experience taking apart motors and removing magnets.

As can be seen, the permanent magnet of a brushed DC motor is fixed and the coils can rotate around the internal center of the motor. The fixed side is called the “stator”, while the rotating side is called the “rotor”.

Below is a schematic diagram representing the concept of the engine structure.

There are three commutators (curved metal plates for switching current) on the periphery of the rotating central shaft. To prevent them from coming into contact, the switches are arranged at 120 degree intervals (360 degrees ÷ 3). The commutators rotate along with the shaft rotation.

Each switch is connected to one end of the coil and the other end of the coil, and the three switches and three coils form a circuit network as a whole (ring-shaped).

Two brushes are fixed at 0° and 180° to contact the commutators. The external DC power supply is connected to the brushes and the current flows along the brush → commutator → coil → brush path.

Working principle of a brushed motor.

① Counterclockwise rotation from the initial state

In the initial state, Coil A is at the top and the power supply is connected to the brushes with the left (+) and right (-) sides defined. A large current flows from the left brush through the commutator to Coil A, and the upper (outer) side of Coil A becomes an S-pole structure.

Because half of the current flowing through left brush coil A toward coils B and C is in the opposite direction to coil A, the outside of coils B and C becomes a weaker N pole (represented by smaller letters in the diagram ).

The magnetic fields generated in these coils and the repulsion and attraction between the magnets cause the coil to rotate counterclockwise.

②Additional counterclockwise rotation

Assuming that coil A is in a state of 30 degrees counterclockwise rotation, the right brush comes into contact with two commutators.

The current in coil A continues to flow from the left brush through the right brush, and the outer side of coil A remains an S pole.

The same current as in Coil A flows through Coil B, and the outer side of Coil B becomes a stronger N-pole.

Since both ends of Coil C are short-circuited by the brushes, no current flows and no magnetic field is generated.

Even in this case, the coil is subject to a counterclockwise rotational force.

From ③ to ④, the upper coil continues to be subjected to a force to the left and the lower coil continues to be subjected to a force to the right, continuing to rotate counterclockwise.

Each time the coil rotates 30 degrees to states ③ and ④, the outer side of the coil becomes an S pole when the coil is located above the central horizontal axis, and an N pole when the coil is located below it, running repeatedly this movement.

In other words, the top coil repeatedly receives a force to the left and the bottom coil repeatedly receives a force to the right (both in a counterclockwise direction). This causes the rotor to continually rotate counterclockwise.

If the power supply is connected to the opposite left brush (-) and the right brush (+), the coil generates a magnetic field in the opposite direction and the direction of force applied to the coil is reversed, causing clockwise rotation.

Additionally, when the power supply is turned off, the brushed motor rotor stops rotating because there is no magnetic field to keep it rotating.

5. Three-phase full-wave brushless motor

Appearance and structure of three-phase full-wave brushless motor

The following figure shows an example of the appearance and structure of a brushless motor.

On the left is an example of a spindle motor for spinning discs in a disc playback device. There are a total of nine coils, consisting of three phases times three.

On the right is an example of a spindle motor for an FDD device, which has 12 coils (three phases times four). The coils are fixed to the circuit board and wound around an iron core.

The disc-shaped component to the right of the coil is a permanent magnet rotor. The outer edge is made of a permanent magnet and the rotor shaft is inserted into the center of the coil and covers part of it. The permanent magnet rotates around the outer edge of the coil.

The diagram of the internal structure of a three-phase full-wave brushless motor and the equivalent circuit for coil connections.

Following are simplified diagrams of the internal structure and equivalent circuit for coil connections.

The simplified diagram shows a 2-pole (2-magnet), 3-slot (3-coil) motor with simple structure. It is similar to a brushed motor structure with the same number of poles and slots, but the coil side is fixed while the magnets can rotate. Of course, there are no brushes.

In this case, the coils are connected in a Y-shaped configuration and semiconductor components are used to supply current to the coils. Current flow is controlled based on the position of the rotating magnets.

In this example, Hall elements are used to detect the position of the magnets. Hall elements are placed between the coils and detect the voltage generated by the intensity of the magnetic field, which is used as position information. In the image of the spindle motor for the FDD device given earlier, Hall elements can also be seen between the coils for position detection (above the coils).

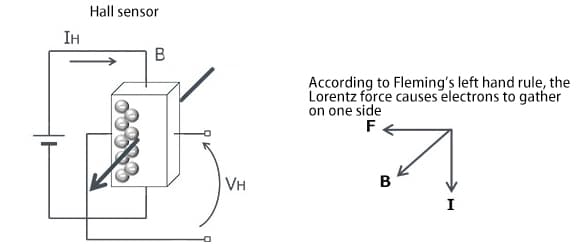

Hall elements are well-known magnetic sensors that convert the size of the magnetic field into the size of the voltage and represent the direction of the magnetic field with positive or negative voltage.

Below is a schematic diagram illustrating the Hall effect.

The Hall element uses the phenomenon that “when a current IH passes through a semiconductor and a magnetic flux B passes perpendicular to the current, a voltage VH is generated in the direction perpendicular to the current and the magnetic field”. American physicist Edwin Herbert Hall discovered this phenomenon and called it the “Hall effect”. The generated voltage VH is expressed by the following formula:

VH = (KH / d)・IH・B

※KH: Hall coefficient, d: thickness of the magnetic flux penetration surface

As shown in the formula, the greater the current, the greater the voltage. This feature is commonly used to detect the position of the rotor (magnet).

Rotational principle of three-phase full-wave brushless motors

The rotational principle of a brushless motor will now be explained in steps 1 to 6. For ease of understanding, the permanent magnet has been simplified from a circular shape to a rectangular shape.

① In a three-phase coil system, coil 1 is fixed at the 12 o'clock position, coil 2 is fixed at the 4 o'clock position, and coil 3 is fixed at the 8 o'clock position on the clock face. A 2-pole permanent magnet with N pole on the left and S pole on the right is capable of rotating.

Pass a current Io through coil 1 to produce an S-pole magnetic field on the outside of the coil. Pass a current of Io/2 through coils 2 and 3 to produce an N-pole magnetic field on the outside of the coil.

When the magnetic fields of coils 2 and 3 are vectorially combined, a downward-pointing N-pole magnetic field is produced. This magnetic field is 0.5 times the magnetic field produced by the current Io passing through a single coil, and when added to the magnetic field of coil 1, it becomes 1.5 times stronger. This produces a combined magnetic field perpendicular to the permanent magnet, which generates maximum torque and causes the permanent magnet to rotate clockwise.

As the current through coil 2 is reduced and the current through coil 3 increases based on the rotational position, the combined magnetic field also rotates clockwise, causing the permanent magnet to continue to rotate.

② In a 30-degree rotated state, a current Io passes through coil 1, making the current in coil 2 zero and causing current Io to flow out of coil 3.

The outer part of coil 1 becomes an S pole and the outer part of coil 3 becomes an N pole. When vectorially combined, the magnetic field produced is √3 (≈1.72) times stronger than the magnetic field produced by the current Io passing through a single coil. This also produces a combined magnetic field perpendicular to the permanent magnet, which rotates clockwise.

As the rotational position changes, the current flowing into coil 1 is reduced, the current flowing into coil 2 starts at zero and increases, and the current flowing out of coil 3 increases to Io. As a result, the combined magnetic field also rotates clockwise, causing the permanent magnet to continue to rotate.

※ Assuming that each phase current is a sine wave, the current value here is Io × sin (π⁄3) = Io × √3⁄2. Through the vectorial combination of magnetic fields, the total magnitude of the magnetic field is 1.5 times the magnetic field produced by a single coil.

When each phase current is a sine wave, regardless of the position of the permanent magnet, the magnitude of the vectorially combined magnetic field is always 1.5 times the magnetic field produced by a single coil, and the magnetic field is perpendicular to the magnetic field of the magnet permanent. field at a 90 degree angle.

③ In a continuous rotation of 30 degrees, a current of Io/2 flows through coil 1, a current of Io/2 flows through coil 2, and a current of Io flows out of coil 3.

The outer part of coil 1 becomes an S pole, the outer part of coil 2 also becomes an S pole, and the outer part of coil 3 becomes an N pole. When vectorially combined, the magnetic field produced is 1, 5 times the magnetic field produced when a current of Io passes through a single coil (same as step 1). This also produces a combined magnetic field perpendicular to the magnetic field of the permanent magnet at a 90 degree angle and rotating clockwise.

④-⑥

Continue turning in the same way as in steps 1-3.

This way, if the current flowing to the coils is continuously switched based on the position of the permanent magnet, the permanent magnet will rotate in a fixed direction. Likewise, if the current flows in the opposite direction and the direction of the combined magnetic field is reversed, the rotation will be counterclockwise.

The following diagram shows the current flowing through each coil for each step 1 through 6.

Through the above explanation, the relationship between current changes and rotation should now be understood.

6. Stepper Motor

A stepper motor is a type of motor that can be precisely controlled in terms of rotation angle and speed by synchronizing with a pulse signal. Stepper motors are also known as “pulse motors”.

Due to their ability to achieve precise positioning without the use of position sensors and with open-loop control only, stepper motors are widely used in equipment that requires positioning.

Stepper motor structure (two-phase bipolar)

The following images, from left to right, show examples of what a stepper motor looks like, a schematic diagram of its internal structure, and a conceptual diagram of its structure.

In the appearance example, stepper motor types HB (hybrid) and PM (permanent magnet) are shown. The schematic diagram in the middle also shows the structure of HB and PM types.

A stepper motor has a structure in which the coils are fixed and the permanent magnet rotates. The conceptual diagram of the internal structure of the stepper motor on the right is an example of a PM motor with two-phase coils (two sets).

In the example of the basic structure of the stepper motor, the coils are arranged on the outside and the permanent magnet is arranged on the inside. In addition to the two-phase type, there are types with more phases such as three-phase and five-phase.

Some stepper motors have different structures, but to explain the basic working principle of stepper motors, this article introduces the stepper motor with the basic structure of fixed coils and rotating permanent magnets.

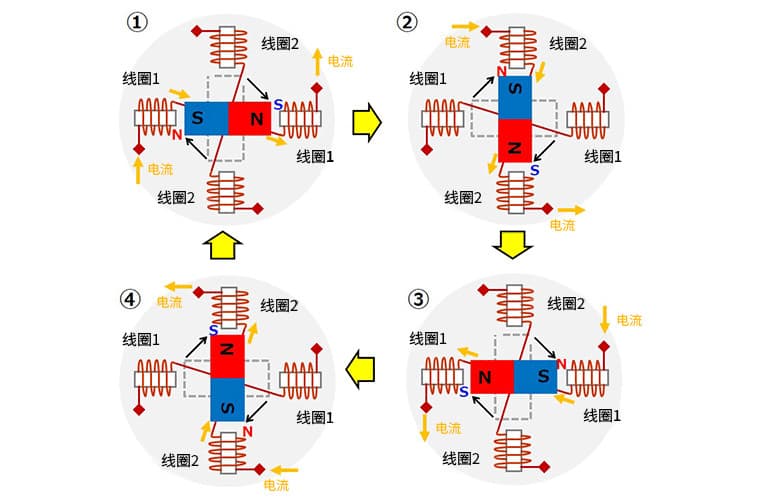

Basic operating principle of stepper motor (single-phase excitation)

The following diagram is used to explain the basic working principle of stepper motor. This is an example of exciting each phase (a set of coils) of the two-phase bipolar coils shown in the previous image, assuming a change of state from ① to ④. The coils are made up of coils 1 and 2, and the current arrow indicates the direction of current flow.

①

Electric current flows from the left side of coil 1 and exits through the right side.

Do not allow electrical current to flow through coil 2.

At this point, the inside of left coil 1 becomes North and the inside of right coil 1 becomes South.

As a result, the middle permanent magnet is attracted by the magnetic field of coil 1 and stops in a state where the left side is South and the right side is North.

②

Stop the current in coil 1 and allow current to flow from the top of coil 2 and out the bottom.

The inside of the upper coil 2 becomes North and the inside of the lower coil 2 becomes South.

The permanent magnet is attracted by its magnetic field and rotates 90° clockwise and stops.

③

Stop the current in coil 2 and let the current flow from the right side of coil 1 and out the left side.

The inside of left coil 1 becomes South and the inside of right coil 1 becomes North.

The permanent magnet is attracted by its magnetic field and rotates another 90° clockwise and stops.

④

Stop the current in coil 1 and allow current to flow from the bottom of coil 2 and out the top.

The inside of the upper coil 2 becomes South and the inside of the lower coil 2 becomes North.

The permanent magnet is attracted by its magnetic field and rotates another 90° clockwise and stops.

By switching the current flowing through the coils in the order of steps ① to ④ using electronic circuits, the stepper motor can be rotated. In this example, each switching action will rotate the stepper motor by 90°.

Furthermore, by continuously flowing current through a specific coil, the stepper motor can maintain its stationary position and have holding torque. It is worth mentioning that reversing the order of the current flowing through the coils can cause the stepper motor to rotate in the opposite direction.