Servo turret punch is a widely used equipment in sheet metal processing. However, with the rapid development of the mechanical manufacturing industry, laser cutting machines have replaced most of the servo turret punch market. Even so, the servo turret punch still has functions that a laser cutting machine cannot perform.

For sheet metal products that need to be formed, the laser cutting machine may not be fully competent. Processes such as rib rolling, step rolling, louver, flanging, convex shell and others require servo turret punch forming die processing.

Therefore, for sheet metal processing, the servo turret punch and forming die remain an indispensable part.

The charm of sheet metal is in the forming, and forming dies are widely used in sheet metal processing fields with forming needs, such as elevators, air conditioners, anti-theft doors, chassis and anti-skid plates. These arrays have the advantages of flexibility, high efficiency and low cost.

The structure of forming dies is complex and the manufacturing process is also complex.

The initial experimental punching of the forming die requires continuous debugging of the die in combination with the forming condition of the part until the part meets the requirements. Consequently, the forming die manufacturing cycle is long, and customers need to be informed in advance when customizing the die to avoid unnecessary contradictions during machine tool delivery.

Type of training matrix

The forming dies in servo turret punch mainly include roller dies, stamping and embossing dies, shallow drawing dies, punching dies, flange dies, draw hole dies, extrusion dies, shear dies, positioning and much more.

Roll die

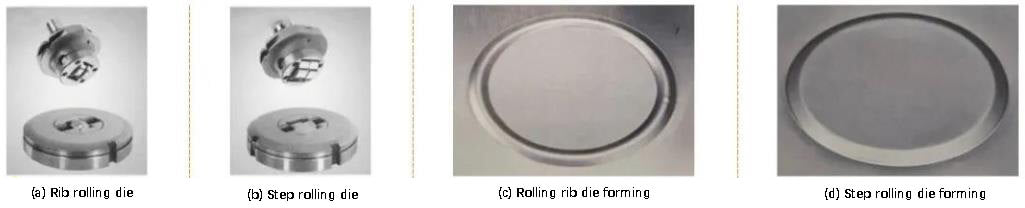

The roll die is composed of rib rolling die and step rolling die. To meet the arbitrary curve shape processing requirements, it needs to be placed on a rotating station. Furthermore, there should be no stamping marks on the plate.

Through the corresponding rollers installed in the upper and lower dies, the up and down movement of the roller and the left and right movement of the sheet metal form a relative movement in the stamping process. This movement helps in carrying out the processing of formation of the long convex rib. The length of the convex rib is not limited by the die.

For rib rolling dies and step rolling dies, determining different forming heights and widths depends on customer requirements. This type of die offers a wide range of stamping ribs, precise positioning and high processing precision.

At the same time, there are special requirements regarding the material and thickness of the workpiece.

- Stainless steel is generally 0.8 ~ 1.5mm;

- Carbon steel plate is generally 0.8~2.0mm;

- The aluminum plate is generally 0.8 ~ 2.5mm;

- The forming height is 2~3 times the plate thickness;

- The width is 2 times the height and the maximum width is 12.7 mm.

The roll die and forming are shown in Fig.

Fig. 1 Die and roll forming

Stamping and engraving die

Engraving and engraving molds include code molds, engraving molds, concave-convex word molds and engraving molds.

Stamping with relief dies and concavo-convex dies can create relief on sheet metal, which can be raised or lowered.

Using embossing dies can help customers eliminate the need for part reprocessing such as labeling and painting, saving money and increasing efficiency.

Engraving die is used to engrave or create matrix markings on the surface of a workpiece. Does not change the shape of sheet metal parts or cause indentations that could affect their appearance.

It can adapt to processing plates of various materials by adjusting the spring.

The forming direction is downward and needs to be placed on the rotating station. Figure 2 shows the stamping, engraving and forming process.

Fig. 2 Stamping and representation of die and forming

Shallow Drawing Template

The shallow drawing die is mainly a convex shell forming die, which consists of a punch and a female die located below it.

The height and forming angle of the convex hull forming die should not be too large to avoid any joint fracture.

The convex hull forming die can work together with the pre-drilling die to meet the requirement of forming through holes in the convex hull.

The pre-drilling die must determine the size based on the results of the trial punching of the holes.

The convex hull forming die is widely used.

The water droplet matrix is similar to the convex hull matrix.

The set of waterdrop convex hulls has an exquisite design and can process a maximum plate thickness of 1.5mm.

The bamboo weaving die needs to collaborate with the punching die, and the maximum plate thickness for stamping medium carbon steel plates is also 1.5mm.

The formation of the shallow drawing die is shown in Fig.

Fig. 3 Shallow design molding

Drill Forming Die

The punching die consists of four main components: plug die, tongue cutting die, bridge die and clamping die.

This type of die is mainly used for ventilation, pipe clamps, decoration and other applications.

Among the four components, the shutter matrix is the most used. It is typically chosen for chassis and other parts that require heat dissipation and an attractive design.

Male cutting die is mainly used to join sheet metal parts, similar to a buckle.

The bridge mold is used to insert wire tubes, providing a simple and convenient solution.

Finally, the fixture matrix is designed for installing electrical components.

Punching die is generally divided into two types: punching and forming. Its complex structure allows it to meet most customer product requirements.

The punching die formation process is illustrated in Figure 4.

Fig. 4 Punching forming die

Flange Forming Mold

The flange forming die must be combined with the pre-drilling die.

The die responsible for turning the edge of the hole after punching is known as the flange forming die.

It is mainly used to form threaded holes and can also be used to install heat dissipation pipes, cable routing and threading plastic pipes.

After the flange molding die shapes the edge, it is smooth without burrs that could scratch the pipe.

It has numerous benefits for punching and direct threading.

Figure 5 illustrates the forming process of the flange forming die.

Fig. 5 Flange forming die

Drop the die hole

A collapsible hole mold is also known as a prefabricated hole mold and can be designed as a single, double or triple strike mold.

There is a partial connection between the scrap and the main body of the part, and the required connection port varies depending on the board thickness and type.

This type of mold is mainly used in distribution boards, among other applications.

Figure 6 shows the process of forming a mold with a detachable hole.

Fig. 6 Formation of the detachable hole matrix

Extrusion Die

The extrusion forming die is mainly used for recess extrusion, serving as a stamping die for recess processing based on pre-punching. It can effectively replace the need for drilling when creating holes.

This die can process workpieces positively and negatively, resulting in extruded recesses that can be used as installation holes for countersunk screws. By using the compression sinking hole die, the drilling sinking process of a drill bit can be omitted, ensuring high quality and processing efficiency.

Figure 7 shows the die formation process for extrusion and hole sinking.

Fig. 7 Formation of extrusion die with sink hole

Shear Die Positioning

The positioning and shear die consists of a sample punching die, a triangular positioning die and a semi-shear die.

The sample drilling die allows control of spot depth based on the height of the die.

The triangular positioning die is used for thin sheets that are difficult to process using the semi-shear die.

It is important to note that the minimum central distance between the positioning points must be 15mm.

The semi-shear die can connect the material and the plate, with the forming height being less than 0.6 times the plate thickness.

The positioning and cutting die is not commonly used and is only customized for special needs.

Figure 8 illustrates the formation process of the positioning shear matrix.

Fig. 8 Positioning and cutting of the die

In case of special requirements, a forming die can also function as a composite die. For example, a convex flange composite die can perform pre-drilling, flanging and convex shell forming at one time.

However, when programming the composite matrix, it is crucial to take adequate discharge time into account. Furthermore, the forming direction must be exclusively upward, and it is worth noting that the cost of a composite die is considerably higher than that of a normal forming die.

Precautions for using the formation matrix

The following points should be noted when using the formation matrix:

(1) Always pay attention to the tightness of the servo turret punch locking screw when using the forming die. Do not punch without sheet metal and avoid punching the empty die to avoid damage to the forming die in the servo turret punch.

(2) Generally, the forming direction of the forming die should be upward to avoid deformation caused by scraping between the forming part of the workpiece and the lower die of the rotary table.

(3) The bottom array of the ascending formation array is generally higher than the standard bottom array. Avoid using the punching die in the next station to avoid indentation of the workpiece. When the forming die is not in use, take it out of the machine tool, coat it with anti-rust oil, and store it in the die box to prevent damage to the die caused by rust and dust.

(4) The stamping stroke of each servo turret punch is different. When using the forming die for the first time, adjust the upper die to the shortest length to avoid die damage and punch failure. Adjust the formation matrix to obtain a complete formation.

(5) For molds with high forming height or special forming, lubricate the plate, strengthen the fluidity of the plate during forming, and reduce the probability of plate damage and tearing.

(6) The workpiece should be positioned as far as possible from the clamping and punching positions during forming, and the workpiece forming step should be completed at the end of the processing process.

(7) Dies with high forming heights can scratch and deform the plates due to collision. This problem can be avoided by placing spherical lower dies on both sides of the lower die of the die with high forming height. Using other molds close to the mold with high forming height to continue processing may lead to deformation of the part.

(8) The forming die processing program must be used during forming processing. Sufficient unloading time must be allowed during programming, and the punch stamping speed must be reduced to minimize impact and allow sufficient time for the formed part to separate from the forming die, thus preventing part deformation and drift from the training position.

By following these precautions for using and maintaining the forming die, we can greatly reduce the damage to the die and effectively produce ideal products using the forming die.

The use of forming dies makes sheet metal processing more efficient and effective.

Conclusion

When selecting the forming die, we must ensure that all requirements are clearly expressed.

In addition, when ordering the servo turret punch, we should also consider whether the stamping stroke of the punch can meet the required forming height of the workpiece.

Despite the growing popularity of high-efficiency and energy-saving methods in sheet metal forming, the servo turret punch still occupies a significant place in the mechanical field.

It is widely believed that the development and application of forming dies in servo turret punching machines will continue to grow in the future.