1. Yield strength

Yield strength is the yield strength of metallic materials when yielding occurs, which is also the resistance to plastic microdeformation.

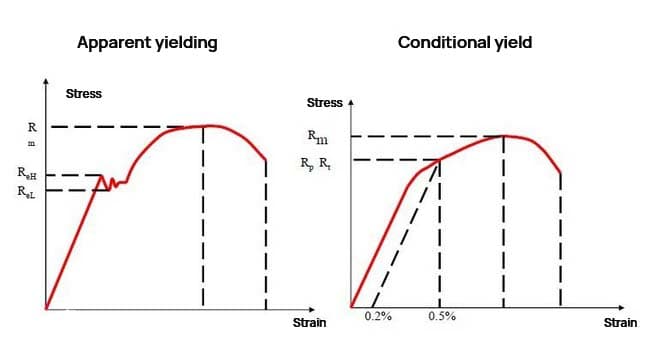

For metallic materials without obvious yielding, the stress value that produces 0.2% residual strain is specified as their yield strength, which is called the conditional yield strength or yield strength.

Some steels, such as high-carbon steel, do not have a clear flow phenomenon. In these cases, the yield point is defined as the stress at which slight plastic deformation occurs (0.2%) and is known as the conditional yield point.

When a force is applied to a material, it undergoes deformation. This deformation can be divided into two types: elastic deformation, in which the material returns to its original shape when the external force is removed, and plastic deformation, in which the material's shape changes permanently, resulting in lengthening or shortening.

The yield strength of construction steel is used as a basis for determining design stress. The yield point, commonly symbolized by σs, is the critical value of stress at which the material yields.

- For materials that exhibit a clear yield phenomenon, the yield point is defined as the stress at the yield point or yield value.

- For materials without a clear yield phenomenon, the yield strength is determined as the stress at which the limiting deviation from the linear relationship between stress and strain reaches a specified value, typically 0.2% elongation of the material.

The yield strength is commonly used as an index for evaluating the mechanical properties of solid materials and represents the actual service limit of the material. When the stress in a material exceeds its yield strength, plastic deformation occurs and the strain increases, making the material invalid and unusable.

2. Enter

1. Mania yield: mania phenomenon and stress relief.

2. Shear yield.

Determination of yield limit

For metallic materials without a clear yield phenomenon, the specified non-proportional stretching strength or the specified residual stretching stress is measured. For metallic materials that exhibit a clear yield phenomenon, the yield point, upper yield point and lower yield point can be measured.

Typically, only the lowest yield strength is measured. There are two common methods for determining the upper yield point and the lower yield point: the graphical method and the pointer method.

Graphical method

During the test, an automatic recording device is used to plot the force-displacement diagram. The stress, represented by the force axis ratio per millimeter, should generally be less than 10 N/mm^2, and the curve should extend to the end of the yield stage at a minimum.

To determine the yield point, the upper yield point, and the lower yield point, the constant force (Fe) at the yield stage on the bend, the maximum force (Feh) before the first drop in force during the yield stage, and the minimum force (FeL) without the initial instantaneous effect are calculated.

The yield strength can be calculated using the following formula: Re = Fe/So, where Fe is the constant force on the yield.

The upper yield point is calculated as follows: Reh = Feh/So, where Feh is the maximum force before the first drop in force during the yield stage.

The lowest yield strength is calculated as follows: ReL = FeL/So, where FeL is the minimum force without the initial instantaneous effect.

Pointer method

During the test, the yield point, upper yield point and lower yield point are determined by measuring the constant force when the pointer of the force measuring disk first stops rotating, the maximum force before the pointer rotates for the first time. first time, and the minimum force that does not reach the initial instantaneous effect, respectively.

3. Patterns

There are three yield standards commonly used in construction engineering:

- Proportional stress-strain limit curve: The highest stress on the curve that conforms to the linear relationship is commonly expressed as σp internationally. When the stress exceeds σp, the material is considered to begin to yield.

- Elastic limit: The elastic limit is determined by unloading the sample after loading and measuring the maximum stress that the material can recover elastically without any residual permanent deformation. It is usually expressed as ReL internationally. The material is considered to be yielding when the stress exceeds ReL.

- Specified residual strain: The yield strength is based on a specified residual strain, such as 0.2% residual strain, which is commonly considered as the yield strength and represented by Rp0.2.

4. Influencing factors

The internal factors that affect the yield strength of materials include bonding, structure, atomic nature, and more. When comparing the yield strength of metals with that of ceramics and polymers, it becomes clear that the influence of bonding is fundamental.

From a structural point of view, there are four reinforcement mechanisms that can impact the yield strength of metallic materials:

- Strengthening the solution

- Deformation strengthening

- Precipitation strengthening and dispersion strengthening

- Grain boundary and subgrain strengthening.

Precipitation strengthening and grain refining are commonly used methods to increase the yield strength of industrial alloys. Of these reinforcement mechanisms, the first three can improve the resistance of the material, but also reduce its plasticity. Grain refinement is the only way to improve strength and plasticity.

External factors that affect yield strength include temperature, strain rate, and stress state. As the temperature decreases and the strain rate increases, the yield strength of materials increases, particularly for body-centered cubic metals. These metals are highly sensitive to temperature and strain rate, leading to low-temperature brittle failure in steels.

The influence of the stress state is also significant, as the yield strength is an important index that reflects the internal properties of materials. However, yield strength values may vary with different stress states. The yield strength is typically referenced to the yield strength in uniaxial tension.

5. Importance of the project

According to traditional strength design methods, the allowable stress (σ) for plastic materials is specified based on the yield strength (σys) and is calculated as (σ)=σys/n, where n is a safety factor which can vary from 1.1 to 2 or greater depending on the situation. For brittle materials, the allowable stress (σ) is specified based on the tensile strength (σb) and is calculated as (σ)=σb/n, where n is generally 6.

It is important to note that the traditional strength design method often prioritizes the high yield strength of materials, which can result in reduced resistance to brittle fracture. As the yield strength of materials increases, they become more susceptible to stress corrosion cracking and hydrogen embrittlement. On the other hand, materials with low yield strength tend to have good formability and cold work weldability.

In conclusion, yield strength is a crucial index in material properties and provides an approximate measure of various mechanical behaviors and technological properties of materials in engineering.