A few days ago we talked to some colleagues about the welding line.

Your upstream customers have very high requirements for the welding line.

I asked if this defect could be eradicated. You may have had similar experiences with such a difficult problem.

Today I will discuss with you the welding line, including its generation mechanism, history and solutions.

1. Welding line mechanism

The weld line, also known as the fusion line or bond line, is formed when the cooled molten resin from the leading edge fails to completely fuse into the joint, resulting in a visible line.

This phenomenon is commonly observed at the point where two chains meet, or where a chain converges after going around certain geometric shapes, such as holes, in the workpiece.

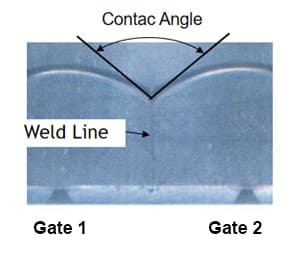

As illustrated in Fig. 1, the material flow from port 1 and port 2 eventually creates a welding line on the surface of the product.

Figure 1 welding line

Let's take another look at the melt flow pattern before the welding line is formed.

Due to the significant temperature difference between the mold and the melted plastic, a frozen layer forms on the surface, resulting in a gap at the joint. The plastic material is unable to perfectly replicate the mold surface.

Increasing the melting temperature improves the feeding effect, but causes the plastic molecular chains on the surface to become misaligned, leading to the formation of a weld line as depicted in Fig.

Fig. 2 copy of the welding line

The two resin streams at the welding point do not mix because they advance while semi-curing in the jet stream.

However, if the temperature is low, the surface layer will become thicker, the texture will become more apparent, and the strength will be reduced due to the weak adhesive force between the two.

2. Welding line hazards

The welding line mainly has two problems.

Firstly, there is a structural problem. Parts are more susceptible to breakage or deformation in the welding line, especially when the quality of the welding line is poor. This weakness is a more serious problem in areas where parts are under stress.

Secondly, there may be visible defects on the surface of the parts. The welding line can cause lines, grooves or color changes on the surface of the parts. If the weld line is located on the surface of a non-critical part (e.g. the bottom), this may not be a problem.

3. Factors influencing the welding line

(1) Temperature

When two resin streams meet, they fuse. The extent of melting is more prominent when the temperature of the resin streams is lower.

On the other hand, if the temperature of the two resin streams is high, the adhesive force between them will increase, resulting in less obvious fusion.

(2) Pressure

At the melting point, the two molten resins are compressed together, and the level of adhesion depends on the amount of pressure applied.

Lower holding pressure results in more pronounced fusion but weaker adhesion. As the healing process continues, transferring pressure becomes increasingly challenging.

Furthermore, if the size of the gate aisle is reduced and the position of the gate is poor, the appearance and strength of the fusion will deteriorate.

( 3 ) Angle

When two flows meet in front of each other, the fusion line is more noticeable when the angle between them is smaller. On the other hand, when the angle is greater, the fusion line is less evident.

In Moldflow, the melt line forms when the melt polymerization angle is less than 135°, and no melt line forms when the angle is greater than 135°.

Although the fusion line is not visible to the naked eye, it is still acceptable.

( 4 ) Exhaust

Melting refers to the point where the resin meets and melts, which can also be the end point of the flow.

If there is inadequate provision of an exhaust port at this location to release gas, the melt quality and strength will deteriorate.

(5) Filling speed

If the filling rate is too slow, the melt flow front may not reach the filling end, and the further the melt is from the port, the more likely it is to freeze. This can result in a poor quality welding line.

Likewise, if the flow length is too long, the melt front temperature may decrease significantly when the weld line is formed at the end. This can also lead to a poor quality welding line.

4. Welding line solution

First, increase the temperature

To achieve better fusion of the two streams at the front, increase the melting temperature when it is low, but be careful not to exceed the material's degradation temperature.

Likewise, it is recommended to increase the mold temperature when it is low to improve the fusion of the material flow front.

The frozen layer in the melt is formed when the temperature is below the material's conversion temperature.

By increasing the mold temperature above the conversion temperature, the melt line problem can be fundamentally solved.

Technically, hot and cold processes, as well as electromagnetic heating, can achieve the aforementioned effects, although at a higher cost than ordinary molds.

Figure 3 shows the welding line effect of high-gloss molds, with the left side representing common molds and the right side representing high-gloss molds.

The mold temperature was increased to over 150°C using hot and cold processes, while the material conversion temperature was around 145°C.

Fig.3 Comparison of welding lines

Second, for insufficient filling end pressure

If the final filling pressure is low, increasing the holding pressure can improve the melting between the two melting fronts. This ensures that the material flow front with the highest temperature is at the cavity wall, where these areas receive maximum holding pressure to activate the shear thinning property of the plastic.

Third, the angle is too small

Adjust the product wall thickness or gate position to increase the melt confluence angle.

Fourth, for trapped gas

Injecting exhaust gas into the filling end can improve the fusion of the front ends of the two castings. However, it is important to ensure that the position of the exhaust is correct, as incorrect positioning of the exhaust will not effectively remove exhaust gases.

Fifth, the filling rate is too slow

It is important to utilize the shear thinning property of the plastic. Increasing the filling rate will increase the temperature of the material flow front, increase the shear thinning effect, and ultimately improve the bond line strength.

When the filling distance is very long, it should be noted that the filling distance should not exceed a certain limit (L/T = length to wall thickness, which should be less than 250:1).

If L/T exceeds 250:1, it is generally considered thin-walled molding. In this case, the flow length ratio can be reduced or a new gate can be added. However, this can lead to improper positioning of a new weld line port.

5. Welding line evaluation standard

In Moldflow, a welding line is formed when the molten polymerization angle is less than 135°, and no welding line is formed when the angle is greater than 135°.

The following is a summary of the experience shared by one company:

A visible weld line occurs when the welding line confluence angle is less than 75°, but is not visible when the angle is greater than 75°, as shown in Fig.

Furthermore, all companies can develop suitable industry standards for their own products based on their requirements for appearance, structural characteristics and material types.

Fig. 4 welding line angle and depth

The forming conditions determine the quality of the welding or fusion line, and the strength of the welding line is influenced by the forming temperature and the pressure applied to the welding before the parts freeze.

The pressure during the formation of the welding line is zero.

Typically, the melting temperature during welding line formation is at least 20°C above the injection temperature to produce a high-quality weld.

6. Welding line resistance analysis

If you want to evaluate the impact of welding line resistance on the product structure and predict the welding surface resistance reduction coefficient, you can perform welding line resistance analysis.

Before carrying out the analysis, it is necessary to test the welding line resistance property of the material.

Using the welding line strength property, you can perform Moldflow flow pressure analysis and then import the welding line results into ANSYS or ABAQUS for further analysis and predict the impact of the welding line on the strength of the structure. product.

Detailed information about line resistance analysis will be shared in future articles, so there won't be much of an introduction here.

7. Summary

The formation of welding lines is closely related to the structure, mold design, process and material of the product.

In the case of holes or multiple ports, it is difficult to avoid the welding line, but it can be mitigated through the dilution process.

However, in some cases, a high light mode is required to completely eliminate the welding line.

It is important to understand the impact of welding lines on the structural strength of the product, and the welding line strength can be analyzed and predicted.