CNC machining has established itself in the manufacturing industry as one of the most versatile and reliable methods of producing parts and products. This process allows the production of a wide range of materials, including metals, plastics and composites.

Although CNC machining is versatile and productive, knowledge of the design process and machine operation is still important if you want to produce high-quality products. That's why in this CNC machining project guide we'll discuss everything you need to know about CNC machining projects and guidelines. So keep reading.

Basic rules when designing for CNC machining

Here are some basic rules to keep in mind when designing CNC machining.

- Design parts for easy machining with large diameter tools as this allows for faster processing and ensures you don't need special tools.

- The depth of the cavities should not be more than four times their width, as this makes processing somewhat difficult.

- When designing, take into account the main direction allowed by your machine, as well as the standard number of axes to avoid complications.

- When editing text, do not use sizes smaller than 20 points to avoid errors in the recorded text.

Design Limitations for CNC Machining

It is true that CNC machining is versatile and not all projects are possible. In other words, there are restrictions and limitations you need to be aware of to ensure smooth editing. The two main limitations of CNC design are:

Tool geometry

Most CNC cutting tools have a limited cutting length. They are also available in cylindrical shapes and geometries. When removing materials from a part, these cutting tools transfer their cylindrical geometry to the part. For this reason, the inside corners of a part always have a radius, regardless of the size of the cutting tool.

Access to the tool

Tool access becomes a major problem when working on a part with a significant depth-to-width ratio. This problem is due to the fact that CNC machines cut by placing the cutting tools on the part from above.

In other words, it would be difficult to machine a part that is not accessible from above. The only exception to this rule occurs with counterbore machining for CNC machined parts.

This tool access problem can be solved by aligning the features of your part or component in one of the six cardinal directions. Additionally, tool access is no longer limited by the use of five-axis CNC machining with excellent part holding capabilities.

CNC machining design guidelines

In the world of CNC machining, there are no universally accepted standards. This is mainly because the industry and the machines used are constantly evolving. However, some best practices and recommendations can help ensure the quality of your design remains excellent. These recommendations include:

1. Inner edges

The vertical corner radius must be at least one-third of the depth of the cavity when creating internal edges. You can use a diameter tool with the recommended cavity depth when using the specified corner radii.

Corner radii slightly larger than the recommended value allow you to cut along an arc rather than a 90-degree angle, producing a better quality surface finish. If you need a 90 degree angle, it is recommended to use a T-bone undercut instead of reducing the corner radius.

2. Holes

To drill holes, machinists may use drills or end mills. It's best to use standard drill sizes, measured in metric or imperial units, as a guide when determining the diameter of the holes in your project.

Technically, any dimension greater than one millimeter is possible. Machine operators use reamers and drilling tools to drill holes that must be within precise tolerances. For holes that require high precision and are smaller than 20 millimeters, it is best to use a standard diameter.

When designing parts for CNC machining, four times the nominal diameter is the maximum suggested depth for each hole, but 40 times is feasible. The nominal diameter is generally 10 times the aspect ratio.

3. Topics

The minimum thread size used in developing CNC machined parts is M2, but generally M6 or higher is ideal. Machinists can limit the risk of thread breakage by using CNC threading machines to cut threads up to size M6.

The minimum thread length should be 1.5 times the nominal diameter, while the recommended length is three times the normal length. For any thread smaller than M6, you must add an unthreaded length to the bottom of the hole that is 1.5 times the nominal diameter. For threads larger than M6, it is best to thread the entire length of the hole.

4. Cavities and pockets

Because end mills have a limit on cutting length, the industry recommended cavity depth for each design is four times its width. A lower depth/width ratio would result in greater chip evacuation, tool deflection and vibration.

Does your CNC project require greater depths? One way to solve this challenge is to use a variable cavity depth and a special tool.

5. Small or raised text

You may need to label parts with part numbers or company names. Adding text looks really cool on custom CNC designs, but it's time-consuming. Electrochemical etching or laser marking are generally better.

Best practices for designing parts with CNC machining

Adhering to best practices and knowing the fundamentals of CNC machining help ensure the high quality of parts or products. With that in mind, here are some best practices to keep in mind when designing parts for CNC machining, depending on the type of machining.

1. Design for CNC milling

CNC milling is a machining technique that uses round cutters to quickly remove material from the raw material and create the desired shape. Milling machines are available in different designs, from 3 to 12 axes.

1.1 Commonly available cutting tools

When developing your CNC part design ideas, consider the many tools commonly used for CNC milling, such as: B. End mills. Costs and delivery time would be significantly reduced if it were possible to produce the required features and geometries using common tools.

When creating your design, also consider standard tool sizes, as a design with a radius smaller than the standard would result in design complications and costs.

1.2 Avoid sharp internal corners

It is impossible to get sharp corners with a milling tool. The reason is that the cutting tool used here is round. To use a CNC mill, your corners must have larger radii than the mill used to create them. Ideally, the diameter of the cutting tool is twice the radius it creates.

Fillets are also needed when a sloped or beveled surface meets a vertical wall or sharp edge. Unless the surface is flat and perpendicular to the tool, a square or ball cutter will always leave material between the wall and the surface below.

1.3 Avoid deep and narrow slots

Long tools often vibrate and bend, resulting in poor surface finish. Therefore, the final cutting depth of an end mill should be no more than 15 times its diameter when cutting plastic, 10 times its diameter when cutting aluminum, and 5 times its diameter when cutting steel.

For example, a groove cut in a steel part machined with a 0.5″ end mill and 0.55″ wide should be no deeper than 2.75″. As the internal radius of the fillet, previous point, also depends on the tool diameter, in this case all internal radii must be greater than 0.25″.

1.4 Construction with the largest possible internal radius

A larger cutter means more material removed per unit of time, which reduces machining time and costs. Always use the maximum allowable internal radii when designing. If possible, avoid radii smaller than 0.8 mm.

Also, make your fillets a little larger than the radius of the end mill. For example, use a radius of 0.130 inch (3.3 mm) instead of 0.125 inch (3.175 mm). The cutter follows a smoother path and gives the surface a finer polish.

2. Design for CNC turning

CNC turning is a machining process that uses a lathe to produce parts with axial symmetry and cylindrical geometry. In this process, the workpiece is held in a rotating chuck while the cutting tool cuts it into the desired shape. This machining process results in better surface quality and tighter tolerances.

Here are some tips for creating a project for CNC cutting with a lathe.

2.2 Avoid sharp internal and external corners

When designing for CNC machining, it is important to avoid sharp corners both inside and out. Adding a radius to the inside corner is one way to ensure that the tool does not pass over a larger surface. Another way to avoid sharp inside corners is to slightly bevel a steep sidewall. Because fewer processes are required, it can be easier to machine contours with a single turning tool.

2.3 Avoid long and thin pieces

Avoid using long, finely turned parts as they are more likely to turn unevenly and rattle in the tool. When making a long piece, try to leave room at the end free for a pilot drill and use a tip to keep the piece turning straight. Additionally, a general guideline is a length-to-diameter ratio of 8:1 or less.

2.4 Avoid thin walls

Similar to milling, removing excessive material can cause unnecessary stress on the part. Very thin walls also reduce stiffness. However, thin walls make it difficult to maintain tight tolerances. For this reason, it is best to keep the wall thickness of the turned sections in your project above 0.02 inches for CNC machining.

2.5 Resource symmetry

Any feature added to a rotating part must generally be symmetrical about the axis of rotation. Adding geometry or features that are not rotationally symmetric requires more complicated editing and configuration steps. Steps, cones, chamfers and curves are great features for turning.

Sometimes it is necessary to add features to a turned part that are not rotationally symmetrical, which may require a different operation. You can maintain a little symmetry even if necessary.

3. Drilling draft

This term refers to processes in which holes are drilled into workpieces. The tools used in this process have a conical tip that allows them to penetrate deeply into the material during machining.

Consider the following suggestions when creating a design for CNC drilling.

3.1 Suitable hole depth

Never drill more than 12 times the nearest drill diameter. This is because drills this long or longer lose rigidity, are no longer able to maintain tight tolerances, and break more easily. If you need to dig deeper, you should also increase the diameter of the hole.

However, if a deep hole is absolutely necessary, another alternative is to drill on both sides of the part. Keep in mind that the manufacturing process takes longer and costs more because a second processing facility is required.

3.2 Avoid partial holes

As there is a high probability of the tip migrating, partial holes should be avoided. However, if only a portion of the hole is needed, hold the drill shaft into the material so that the piece can accommodate most of the hole.

3.3 Keep the drilling axis perpendicular to the surface

The drilling axis must be perpendicular to the surface to prevent the tip from deflecting. A shallow, flat-bottomed pocket milled into the surface of a round object usually allows the bit to enter perpendicular to the surface of the part. The best way to solve this problem is with a pilot hole, although this choice becomes more necessary in programming the CNC machine than in designing the CNC part.

3.4 Avoid drilling cavities

Make sure there are no voids present in the part when planning hole locations in your CNC project ideas. The hole can easily intersect the cavity if necessary, as long as the central axis of the hole does so.

Get your CNC machining design parts with WayKen

Who are we? We are a CNC machining design and manufacturing company with years of experience designing and manufacturing products and parts for various industries. Our CNC workshop has a line of 3 to 5 axis CNC machines and a team of professional designers, engineers and machinists ready to work on your project, regardless of complexity.

Common questions

What is CNC design?

CNC stands for computer-aided numerical control. It is a manufacturing process in which a machine is equipped with control codes to cut a part into the desired shape.

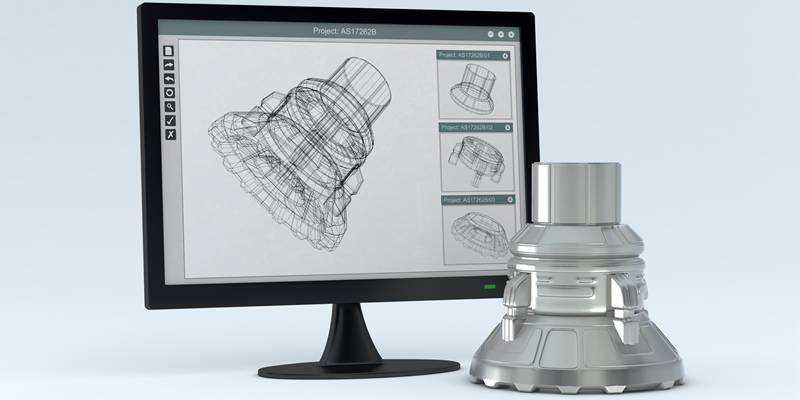

What software is used to design CNC parts?

The design software used for CNC design is called CAD (Computer Aided Design). This software creates the design, which is then transferred to CAM (Computer Aided Manufacturing). CAM then converts the design into G code, the language understood by CNC machines.

What criteria are used to design CNC machine tools?

Speed, rigidity, load capacity and tool life are the four main factors you need to consider when designing CNC machine tools. CNC machines with linear guides are typically faster, but are ideal for lighter applications.