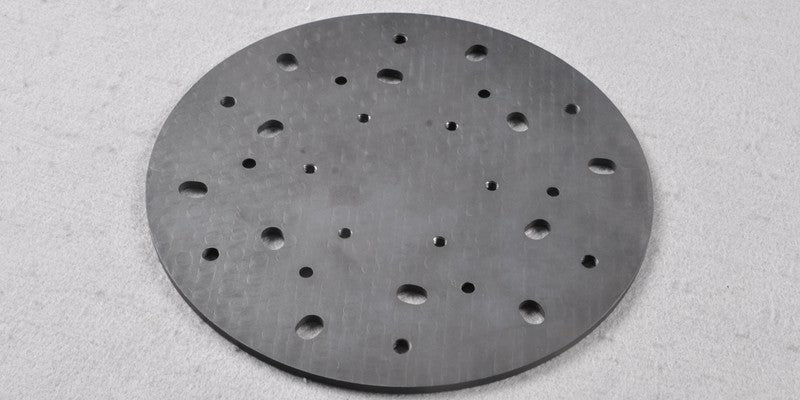

In mechanical and mechanical engineering, a hole is an opening or cavity that is drilled or drilled in a workpiece. Holes can have different shapes, sizes, depths and orientations, which play a crucial role in improving the functionality and performance of the finished product.

This article will discuss the different types of holes in machining and show you how to choose the best hole type for your project.

What does hole features mean when machining?

The general definition of a hole in machining refers to a three-dimensional opening or cavity that extends from the surface of a part to its interior. If you look at the products we use every day, you will see that almost all of them contain a hole, from our kitchen utensils to our cars. Therefore, it is one of the most important features in any manufacturing industry.

The holes are generally considered to be cylindrical in shape. However, there are numerous machining processes that can produce holes of various shapes, including square, rectangular, stepped, oval and tapered. Additionally, some machining techniques for creating holes include drilling, boring, reaming, threading, broaching, and laser drilling.

Hole Features

The design or 3D model of a part or product determines the required hole and its characteristics, thereby determining which machining operations and measuring tools are suitable for creating that specific hole.

Typically, a design includes the following characteristics of a hole;

- shape and size

- depth

- Hole location

- Hole Tolerances

- Surface Finish Requirements

- Chamfer the edges or bottom of the hole

Typical hole types

Holes are classified into different types in engineering and engineering industry depending on their specific functions and requirements. Each type of hole serves a specific purpose. Now let's talk briefly about each of these types of holes.

1. Simple hole

A simple hole is a simple feature used in manufacturing. It is a straight cylindrical hole with a circular cross-section that is drilled into a workpiece. The hole has a constant diameter and extends through the entire thickness of the material. Single holes are often used for spacing, positioning, or mounting purposes.

2. Through hole

A through hole extends completely through the material. It basically contains an opening on both sides of the material. These openings can be used to connect two pieces of material or to allow fluid to flow through the material. This design allows greater flexibility in the use of the material and can be found in several applications.

3. Blind hole

A blind hole, also known as a blind hole, is a cavity that does not go through the entire material. The hole is closed at the bottom and provides a recess for screws, fasteners, slots, dowels and other components.

Blind holes are often used in woodworking and metalworking to ensure a tight fit and to hide screws or parts for a better appearance. Using blind holes can also create complex shapes, which is important in industries where precision is required.

4. Tapered hole

A tapered hole is a hole whose diameter gradually changes from one end to the other. This type of hole can be used for different purposes. For example, tapered holes can be used to create an interference fit, a type of connection that holds two components together through pressure.

5. Threaded hole

A threaded hole is a threaded hole created by cutting threads into the material. The thread cutting process is used to create these threads. Threading is done with a special tool called a tap, which is used to cut threads in the material.

Threaded holes are often used to accept screws or nuts and provide a secure method of attachment. This method of fastening is often preferred over other methods due to its ease of use and reliability.

6. Countersunk Hole

A counterbore is a hole that is larger and deeper than an existing hole. A flat surface is created around the hole by drilling a cylindrical depression in a material. This flat-bottomed hole has a larger diameter at the top, providing a surface for the head of a screw or stud to rest on. This will prevent the screw or bolt from protruding above the surface.

Countersink bits are useful in metal and woodworking because they create a precise, flat surface. They can also be used to hide screw heads or nuts.

7. Lower

A counterbore is a cone-shaped hole created by drilling a material. This is done to ensure that the head of a screw or stud is flush with the surface of the material. This ensures that the surface is flat and that no part of the screw or stud protrudes. This is particularly important in applications where there is a risk of protruding parts causing damage or injury.

Depending on application needs, countersinks can be manufactured in various sizes and shapes and used with a variety of materials, including wood, metal and plastic.

8. Accountant exercises

Counter bits are an essential addition to any toolbox. They are used to create a recess for the head of a fastener so that it is flush with the surface of the material. This provides a more aesthetically pleasing finish and ensures that the fastener is securely in place.

Countersinks are used in many industries to create precise and secure fasteners, which are essential to safety and quality.

9. Drill the hole

A flat bottom hole is a flat bottom hole drilled in a material to create a flat surface for a washer or other component. This is an important technique that ensures even distribution of force and prevents damage.

These holes can create a flat surface around a hole for a screw or screw and improve the appearance of the product by providing a smooth surface.

Other types of hole

- through hole : A hole larger in diameter than the screw or screw it passes through, allowing the screw or screw to move freely.

- Drilled Hole : Refers to holes that are smoothed and calibrated with a reamer to obtain accurate diameter and surface.

- Overlapping Hole : A hole that overlaps another hole is often used in sheet metal manufacturing to join parts together.

- Broken hole : Discontinuous holes that have breaks or breaks in their shape.

Quick View: A Table for Hole Types

| Hole type | Purpose | form |

| Simple hole | For release, location or assembly purposes | Straight cylindrical hole with circular cross section |

| through orifice | Used to join two pieces of material together or to allow fluid to flow through the material. | Contains an opening on both sides of the material |

| blind hole | Ensures a perfect fit and hides any screws or parts for a better appearance | A cavity that does not extend through the entire material |

| Conical hole | Used to create a pressure fit | The diameter gradually changes from one end to the other |

| Threaded hole | To hold screws or nuts | The threaded hole created by cutting threads into the material |

| Countersunk hole | Used to create a flat surface around the hole | The hole that becomes larger and deeper than an existing hole |

| Sink | It ensures that the head of a screw or bolt can be flush with the surface of the material | The cone-shaped hole is created by drilling into a material |

| Counter drill | It creates a depression for the fastener head so that it is flush with the surface of the material. | They are created by expanding the existing hole with a suitable drill bit |

How to choose the right type of hole?

Choosing the right type for your machining or manufacturing projects depends entirely on the part's requirements, specifications, end use and material type. Following these steps will help you choose the right hole type for your project and ensure a successful outcome.

- Consider end use or purpose : Determine the purpose of the hole and the type of material you are working with. This will help you decide the size and shape of the hole.

- Determine the size and shape : Determine the size and shape of the hole depending on the purpose. The most common shapes are round, square and rectangular.

- Type of material : The type of material you are working with will determine the type of hole saw or drill bit you need.

- hole depth : Determine the required hole depth. This will help you choose the correct hole saw or drill length.

- Power Source : Choose the right power source for the job. For example, if you are drilling through thick or hard materials, you may need a more powerful drill.

Concluding

Holes play a crucial role in improving the functionality and performance of the finished product. However, choosing the wrong type of hole and poor quality machining can significantly affect the final result. Therefore, it is important to do thorough research and consult experts before making a decision.