Each machine requires a power source to perform certain tasks. The electric motor is mainly used as a power source for industrial machines. In addition to the electric motor, other main engines such as steam turbine, hydraulic turbine, wind mill, etc. are also used in some specific applications. The mechanical power transmission system recovers the mechanical power from these main engines and subsequently supplies it to the machine unit. It can also change the rotation direction and change the rotation speed to better meet the requirements.

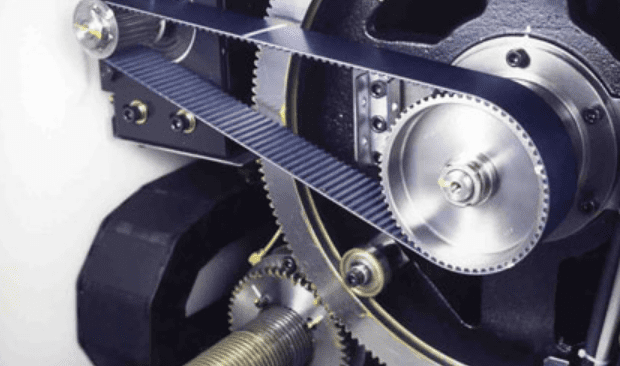

A transmission system includes four types of transmissions (gear transmission, belt transmission, chain transmission and rope transmission) and some elements (pulley, sprocket, shaft, key, coupling, brake, clutch, etc.). Each unit has some advantages over others and is suitable for specific applications.

These four mechanical drives can be classified in different ways. Based on the means of power transmission, such drives can be classified as friction drive and plug-in drive . In friction drives, power is transmitted through the friction force between two coupled parts, as is the case with belt drives and rope drives. In clutch drive, power is transmitted by successive engagements and disengagements, as is the case with chain drive and gear drive. Another criterion for classifying mechanical drives is the presence or absence of flexible elements. A flexible drive consists of a flexible element intermediate between the motor and the driven shafts, as in the case of belt, chain and cable drives. Therefore, a hard drive does not contain any intermediate elements. Here two rigid bodies remain in direct contact, for example the gear.

Another criterion for classifying mechanical drives is whether they can provide a constant speed ratio. A positive drive is free from slip, creep and polygonal effect and can therefore provide a constant speed ratio. Only gear transmission satisfies this condition; while three other units are non-positive units. Therefore, gear transmission is a positive clutch type transmission used to transmit motion, torque and power between the engine and driven shafts, preferably over a short distance. Since it is a hard drive, it can transmit great power without noticeable problems. On the other hand, belt drive is a friction drive specifically suited for transmitting power over medium to long distances. Below are various differences between gear drive and belt drive in table format.

Table: Differences between the 2 types of transmission

| Gear transmission | Belt transmission |

|---|---|

| Gear drive is a type of plug-in drive. | Belt drive is a type of friction drive. |

| In gear drive, the motor and driven shafts are connected by rigid links. There is no intermediate flexible element between the two axes. | In belt drive, the motor and driven shafts are connected by an intermediate flexible element (belt). |

| It is a positive impulse; therefore, the speed ratio remains constant. | It is a non-positive impulse, as slips and slides occur frequently. |

| The transmission cannot protect the system against impacts and overloads. | The insertion of the belt drive helps protect the system against impacts and overloads. |

| It is unable to isolate the drive shaft from vibrations in the driven shaft. | The intermediate flexible element can absorb vibrations and thus protect the crankshaft. |

| It can transmit large torque and power. | Belt drive is not preferred to transmit high torque and power. |

| High speed reduction can be achieved easily. | It cannot provide a strong reduction in speed. |

| It is suitable for transmitting energy and movement over short distances. | It is suitable for transmitting power and movement over medium to large distances. |

| The motor and driven shafts rotate in opposite directions. To achieve rotation in the same direction, an additional gear is required. | Drive and drive shafts can be rotated in the same or opposite direction using a flat or closed belt system. |

| The transmission cannot tolerate small amounts of angular or positional misalignment. | A small amount of angular or positional misalignment is not a problem with a belt drive. |

| The transmission requires complete lubrication. Their initial and maintenance costs are also higher. | Lubrication is rarely required in belt transmission. Additionally, your initial and maintenance costs are lower. |

| Here line contact occurs between two corresponding gears, resulting in low friction and low power loss. Therefore, it provides high efficiency. | Here contact occurs between the belt and the pulley. Therefore, the power loss is more due to high friction, which also results in lower efficiency. |

| Gear performance is not affected by small changes in atmospheric temperature. | The length of the belt increases with increase in temperature and therefore undesirable slippage occurs. |

Clutch drive and friction drive: in mechanical transmissions, the transmission of movement and power between two shafts can occur through friction or coupling. In belt transmission and rope transmission, the frictional force between the pulley and the belt or rope is used to drive the driven shaft. Therefore, these are classified as friction. Here the power transmission capacity is based on the friction characteristics of the contact surfaces. On the other hand, in gear transmission and chain transmission, subsequent engagement and disengagement help to drive the driven shaft. Therefore, they are called engagement drives. Here the frictional force does not play any direct role in power transmission.

Presence of an intermediate flexible element: in gear transmission, two corresponding gears come into direct contact through teeth. There is no intermediate link between two gears. That's why it is also called a hard drive. On the other hand, there is a flexible intermediate link in three other mechanical transmissions. For example, in belt transmission, the belt itself is a flexible connection between two pulleys. This flexible element can absorb vibrations generated on the driven shaft; and therefore can protect the crankshaft. This intermediate link also provides long-distance power transmission without unnecessarily increasing the weight of the system.

Positive drive: A positive drive is capable of providing a constant speed ratio during operation. These transmissions are free from slipping, sliding, polygonal effect, losses, etc. A gear transmission is a positive transmission. On the other hand, friction drives (belt and rope drives) are affected by slipping and sliding. Although chain drive is non-slip, it may not provide a constant speed ratio due to the polygon effect. So these are non-positive impulses. The V-belt and rib tend to eliminate slippage; however, they may not necessarily provide a constant speed ratio, especially when the temperature of the work environment varies substantially.

Vibration Damping: One of the advantages of the flexible drive system is its inherent ability to absorb vibrations. The intermediate flexible element can isolate the main engine from any vibration generated in the machine unit. In belt drive, the belt can dampen vibration and thus protect the electric motor. However, in gear drive, this flexible connection does not exist and therefore vibrations can be transmitted from the machine drive to the main motor, which can be dangerous in some cases.

High Power Transmission: In high power transmission gears, two rigid bodies come into contact to transmit torque from the driving gear to the driven gear. The transmission capacity mainly depends on the gear size, tooth size and gear material. In general, gear transmission can be used from low-load applications (such as toys, watches, etc.) to heavy-duty applications (such as gearboxes, marine transmission, etc.). In belt drive, the transmission capacity depends on the friction characteristics between the belt and the pulley, as well as the initial tension given to the belt. As the belt automatically gradually increases in length, slippage occurs frequently. Not preferred for heavy load transmission, especially in high speed applications.

Sharp reduction in speed: o The tangential speed (measured in m/s) of any axially symmetric body is proportional to the rotational speed (measured in rpm) and the diameter of that body. For all mechanical drives, the tangential speed of two corresponding parts must be the same. Therefore, by changing the diameter of the driver and driven elements, it is possible to vary the rotation speed. For example, by increasing the diameter of the drive pulley while keeping the drive pulley unchanged, it is possible to obtain a low rotation speed. Gear transmission can provide very high speed reduction, starting from 1:1 to 1:100 in one step. Belt drive, being a friction drive, is not suitable for high speed reduction. It is preferred for reduction from 1:1 to 1:4.

Distance between the engine and the driven shafts: In gear transmission, the teeth of two corresponding gears come into direct contact for transmission of force. There is no intermediate link here. To transmit energy over long distances it is necessary to use loose gears, which consume a lot of space and increase the weight of the system. In this scenario, neutral gear can also be used, but the power loss and system weight increase. Therefore, gear transmission is preferred for transmitting power over short distances. On the other hand, in belt drive, two pulleys are connected by an intermediate flexible belt. Belt length may vary based on the center distance between the pulleys. Therefore, it can be advantageously employed for short to long distance power transmission. The V-belt is preferred for short distances, while the flat belt (open or crossed) is suitable for long distances.

Direction of rotation: If the driving gear rotates clockwise, the driven gear will rotate counterclockwise or vice versa. To achieve rotation in the same direction, an intermediate gear must be used, which complicates the design and increases power loss. In belt drive, the motor and driven shafts can be rotated in the same or opposite direction simply by using the belt drive open or closed. However, only the flat strip offers this opportunity; The V-belt is always kept in open configuration.

Correcting error: Minor angular and positional inaccuracies may occur randomly when attaching the gear or pulley to the shaft. Although different types of gears can transmit power in various angular positions, it is necessary to fix two corresponding gears with corresponding shafts while maintaining high precision. Any misalignment will cause vibration, noise and rapid tooth wear. A larger error in gear setting can also affect the speed ratio. On the other hand, belt drive can tolerate small misalignments; however, it cannot transmit power between two non-parallel shafts.

Lubrication: As two rigid bodies remain in continuous contact, lubrication is highly desired in gear transmission. In most high-speed or heavy-duty applications, gear transmission requires complete lubrication, where the gears (fully or partially) are immersed in lubricating oil. This lubricating oil reduces friction, eliminates generated heat and also removes wear debris. Lubricating oil cost as another considerable factor for gear transmission. Belt drive requires occasional lubrication. In fact, greater lubrication than desired will increase slippage and, therefore, energy waste will be greater.

Efficiency: Although the gear drive is rigid, the contact is line contact (higher torque). Landslides or other relevant power loss phenomena are not associated with it. Furthermore, it is always kept under full lubrication. Therefore, gear drive offers high efficiency, generally above 99%. On the other hand, the belt drive is a friction drive and has surface contact between the pulley and the belt (lower torque). Power loss due to friction leads to a reduction in belt drive efficiency (approximately 92 – 96%).

Impact of atmospheric temperature: o Gear transmission is not affected by small changes in atmospheric temperature and other factors such as humidity. Lubricating oil, which has a high heat capacity, tends to mitigate the effects of this variation. As the belt remains open to the atmosphere, a small variation in environmental conditions can degrade performance. Belt length increases with temperature. Therefore, slip increases with increasing tempering.