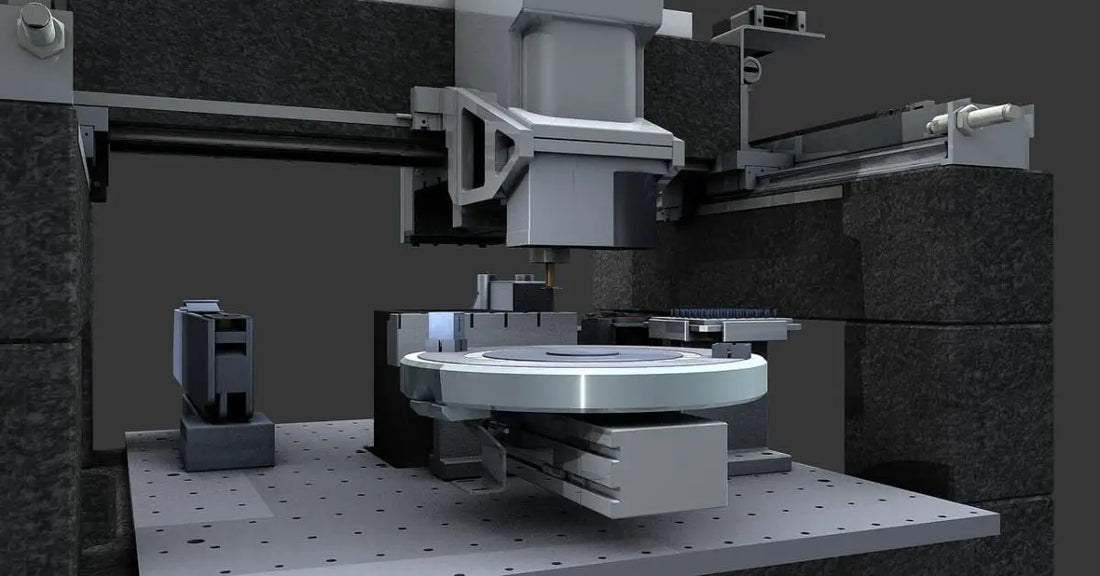

As we know, CNC machine tools are advanced and high-tech products that evolved between the 1970s and 1990s and cannot be interchangeable. Failure phenomena are unique and different, particularly with large and heavy CNC machine tools, which are expensive, cost several million dollars each, and require extensive installation and adjustment time, ranging from a few months to more than a year.

Large-scale CNC machine tools have thousands of components, and the failure of any one of them can result in abnormal machine tool behavior and problems with wire and tube connections. Even a small oversight can cause problems. Additionally, these large, heavy-duty CNC machine tools are bulky and are often used in non-temperature controlled environments, making them vulnerable to environmental impacts that can cause failure.

As a result, the issue of “challenging maintenance” of CNC machine tools is brought to the fore. With so many CNC machine tools imported and manufactured in China, how can we promptly identify potential faults and dangers and resolve them in a timely manner? How can we repair these expensive equipment?

In my opinion, first of all, we must have a strong sense of responsibility and the determination to overcome difficulties. Secondly, we must strive to master numerical control technology and take advantage of my more than ten years of experience in repairing numerical control machine tools.

We should observe more, ask more questions, remember more, think more critically and practice more to gradually improve our technical level and maintenance ability to deal with complex situations and repair numerical control machine tools effectively.

1. See more

To observe further, we must:

Gain an understanding of the features and functions of various CNC systems and PLC programmable controllers.

Acquire knowledge of CNC system alarm and troubleshooting methods.

Learn the importance of setting parameters of NC and PLC machine tools.

Become proficient in the PLC programming language.

Gain an understanding of NC programming methods.

Familiarize yourself with how the control panel works and the details of each menu.

Understand the capabilities of the cutter's spindle and motor, as well as the characteristics of the driver, etc.

1. Read more NC data

But when there is a large amount of numerical control data, how do we make a choice?

The most important aspect is to emphasize crucial elements and provide clear context.

It is essential to understand the fundamental composition and structure of the CNC system and be proficient in the block diagram.

While the rest of the information can be reviewed, each component must be fully understood and given due importance.

Since the internal circuit diagram of the CNC system is quite complex and the manufacturer may not provide it, there is no need to delve into its details.

For example, the NX-154 four-axis five-link blade processing machine uses the A-B10 system.

It is crucial to understand the role of each component, the function of each board, the purpose of the interface, the meaning of the LED lights, etc.

There are several types of CNC systems that are constantly being updated.

Different manufacturers and models often present significant variations.

It is important to understand their similarities and differences.

Typically, those familiar with Siemens CNC system maintenance may not be experts in AB system troubleshooting.

Therefore, it is necessary to continue learning and updating knowledge.

2. Read and understand the electrical diagram

Each electrical component such as contactor, relay, time relay, etc., and the inputs and outputs of the PLC must be clearly indicated in the electrical diagram.

For example, 1A1 represents the contactor that drives the 1M hydraulic pump motor.

The location of its normally open and normally closed contacts is normally indicated on the diagram.

Thus, the normally open or normally closed contact 1A1 can be marked with the hydraulic pump motor running.

The electrical diagram for large-scale CNC machine tools can be dozens or even hundreds of pages long, making it time-consuming to understand the function of each component.

You may not immediately understand the function of a component after reading it once or twice, so it's important to read it several times and take notes.

The 1M starting hydraulic pump motor must also clearly indicate which external output of the PLC triggers the action of the 1A1 contactor, making the context clear.

For certain block diagrams in the electrical circuit diagram, such as the driver for each axis, only one block diagram is provided.

However, as long as you understand the control condition (on-off condition), you can spend some time studying and examining the details.

It is important to note that electrical symbols vary between countries.

It is crucial to have a clear understanding of them.

For the comprehensive PLC instruction tables provided by the manufacturer, it is important to spend time reading and mastering its programming language, writing it down and translating it into Chinese based on your understanding.

This can significantly reduce the time needed to troubleshoot issues in the future.

If you familiarize yourself with the PLC wiring diagram and instruction table only after a fault has occurred, it will take a significant amount of time and may result in incorrect judgment.

3. Read more hydraulic and pneumatic diagrams and gain in-depth knowledge

For CNC machine tool mechanical, hydraulic, and pneumatic diagrams, it is important to understand their functions and context.

It is necessary to note in the drawing that, for example, the process of installing accessories and tools on the German COBURG CNC gantry milling machine is relatively complex.

The diagram must be detailed, such as which solenoid valve is responsible for locking the tool and which are the corresponding inputs and outputs of the PLC.

The electrical and mechanical actions must be clearly indicated in the figure, making it easier to understand at first glance.

At the same time, special attention must be paid to components that have a close relationship between the machine and electricity.

For example, the Italian CNC milling machine INNSE adopts electro-hydraulic proportional valve technology, and it is important to focus on understanding its function, especially its adjustment method and data.

In both static and dynamic scenarios, it is important to understand the proportional valve current and corresponding balancing pump pressure, as well as the integration of electricity, machinery, and electromechanics.

By mastering a wide range of skills, problem-solving ability greatly increases.

4. Improve your professional foreign language reading ability

If you are not proficient in foreign languages, especially English, it can be challenging to understand a large amount of foreign technical material.

Simply relying on translation is often not the ideal solution.

Reading technical materials in a foreign language can be difficult at first as there are many new terms to learn.

However, with continuous reading and memorization, it becomes easier as there are only a limited number of commonly used professional words.

A competent maintenance professional must have a basic command of language tools.

2. Ask more questions

1. Ask more foreign experts

If you have the opportunity to participate in training abroad or foreign experts come to your factory to install and debug machine tools, it is better to participate.

This is the ideal learning opportunity as you can gain a lot of first-hand information and machine tool debugging techniques and skills.

For example, after measuring the accuracy of each laser axis, learn how to correct it electrically, etc.

Ask lots of questions and be sure to clear up any misunderstandings.

With this experience you will gain a lot, including access to confidential internal information and user manuals.

After the machine tool is put into formal production, it is important to maintain close contact with relevant foreign experts.

Via fax and email, it is important to seek guidance on how to resolve challenging machine tool failures and obtain specialty replacement parts.

It is also important to maintain a good relationship with CNC system agents, such as Siemens and FANUC, asking questions and obtaining timely information and relevant spare parts for the CNC system.

In addition, we can take advantage of opportunities to participate in specialized courses on the CNC system.

2. The entire fault request process

When a failure occurs, it is important to thoroughly ask the operator about the entire process that led to the failure.

Failure to collect accurate field data can result in incorrect judgments and complicate the problem.

Therefore, it is necessary to ask detailed questions to understand the entire failure process, including the beginning, middle and end, the alarm number generated, the components that were in use, the changes made and the external environment.

Based on a thorough investigation of the scene and a thorough understanding of first-hand materials, it is crucial to accurately list the failure issues, effectively resolve the issues that have already been identified, and then analyze and resolve the remaining issues.

Experienced and qualified operators are familiar with machine tool operation, processing procedures and common problems.

Close collaboration with them is very beneficial for quick problem resolution.

3. Ask other maintenance personnel more

When other maintenance personnel are repairing a machine tool and you are not there, when they return it is important to ask questions about the recent repair. Ask about their troubleshooting process and how they resolved the issue.

This is a valuable learning opportunity. You can learn the correct troubleshooting techniques and methods from others, especially experienced maintenance personnel, and improve your knowledge and skills.

3. Remember more

1. Relevant parameters must be recorded

It is important to focus on recording various relevant parameters after machine tool adjustment, such as NC machine tool parameters, PLC machine tool parameters and PLC programs (which can be stored on disk), as well as current, voltage, speed, and other data from the spindle and each tool's power motor.

Furthermore, it is necessary to record the state (on or off) of relays, contactors, etc. on the electrical panel during initialization and formal processing, as well as the state (lit, dark, flashing) of all PLC inputs and outputs. LED lights up or if the status of PLC IB (input bit) and QB (output bit) on the screen is 0 or 1, for example, IB1=:00000001, meaning I1.0=1 and I1.1-1.7=0 .

This record is extremely useful for future analysis and judgment of failures.

For example, if Z-axis motor current relay action occurs on a German Schiess CNC vertical lathe, these records will be beneficial.

By quickly checking the PLC state (0 or 1) of the Z-axis motor during normal operation and comparing it with the abnormal state, the cause of the failure was easily identified.

One of the comparison relays was found to be in an incorrect state.

With the adjustment, the fault was resolved promptly.

2. Record hydraulic and pneumatic status

Likewise, it is important to record the readings of various pressure gauges and barometers, as well as the suction and disconnection status of solenoid valves during normal and non-normal hydraulic and pneumatic processing. This information is extremely useful for tuning and fault judgment.

For example, the static pressure of an American Ingersoll open head CNC mill uses dual film technology and has more than 100 pressure measurement points.

The pressure level directly impacts the normal operation of machine tool functions, making it crucial to record static and dynamic pressure.

3. Carry a notebook with you

It is important to keep a record of failures that occur every day, along with the process of how they were resolved. The human mind can easily forget things over time, so having a written record is extremely beneficial.

It has been observed that some faults in CNC machine tools are frequently recurring and are always the same faults. By reviewing how they have been resolved in the past, these failures can be quickly resolved in a matter of minutes.

It is recommended to keep a “CNC machine tool operation diary” and a “CNC machine tool troubleshooting log book”. These two materials must be well documented.

This creates a complete history file of the CNC machine tool.

4. Think more

1. Think more and broaden your horizons

Sometimes it can be difficult to diagnose a repair problem as there may not be a clear analysis available.

I remember a situation where the Y axis of a Coburg gantry milling machine stopped unexpectedly during operation and the screen displayed several dirt alarms on the 1361Y axis grid. Despite cleaning the ruler and the grid head, the machine remained off.

It took several days to identify the root cause, which was eventually determined to be a problem with the wire connecting the Y-axis grid head and the EXE amplifier. Over time, the serpentine tube became bent, causing one of the position feedback lines to break, resulting in the machine stopping.

At the time, we only focused on the static state of the machine and neglected its dynamic state. There was an open circuit alarm control circuit 1321, but we were unable to give it adequate attention.

To avoid similar problems in the future, it is important to keep a record of all alarms and faults that occur and carry out a comprehensive assessment, eliminating false possibilities and focusing on the most likely cause. By doing so, we can better predict potential failures and take steps to resolve them.

“At the end of the journey, there is a brighter destination waiting, but one must carefully consider to reach it.” Let's think deeper to find the solution.

2. Think more and know why

When troubleshooting, it can be frustrating when the root cause of a problem remains elusive, leading to persistent crashes.

I remember a case where the SL mainshaft of an Ingersoll rotor blade root canal mill suffered frequent “automatic shutdowns” after running for just two hours. An overseas expert attempted to resolve the problem by replacing the sequence card and appeared to be successful, but the problem reoccurred after a month.

Although replacing the sequence card standby card appeared to be a solution, the underlying cause was unclear. After careful inspection, we discovered that the reverse peak voltage of the optocoupler corresponding to the “start” command was abnormally high with the help of an oscilloscope. We were able to solve the problem by adding a ground wire, which significantly reduced the reverse peak voltage of the optocoupler.

Since then, the “auto-shutdown” failure has not occurred again, as the high reverse peak voltage was causing the optocoupler to gradually fail over time.

3. Think more and consider taking the lead

Spare parts for electrical machines and appliances must be carefully selected based on frequency of use, repeatability and expected service life. This is crucial to maintain continuous and normal operation of the machine tool.

In some cases, delay in replacement or difficulty in obtaining replacement parts may lead to their unavailability or high cost on the market. To resolve this, it is important to consider this in advance and plan accordingly.

For example, a photoelectric reader used in CNC machine tools in the early 1980s required a belt to read the processing program in loop mode and select the original data in spool mode. If the belt were to become unavailable, the entire machine tool would become inoperative, resulting in serious consequences. To overcome this problem, we collaborated with relevant units and after several tests, we adopted a floppy disk processor, ensuring continuous use of the machine tool.

It is important to think ahead, provide reasonable suggestions to leaders, and strive to improve the external environment of CNC machine tools by considering factors such as temperature, dust, humidity, etc. and air-conditioned cabinets, which can significantly reduce the failure rate of machine tools.

5. Practice more

1. Practice more, dare to do it and be good at it

Maintenance personnel must demonstrate a combination of boldness and caution in carrying out their duties. Simply talking about repairing CNC machine tools is not enough; they must take steps to carry out the repair effectively.

However, it is important not to act blindly without being familiar with the situation, as this could worsen the failure and result in a potentially dangerous accident.

In addition to being bold and cautious, maintenance personnel must also be skilled in practical tasks.

To begin, they should familiarize themselves with the machine tool control panel and understand the functions of each menu. This knowledge will allow them to operate the different models and systems with ease.

They must also take full advantage of the CNC machine tool's self-diagnosis technology to quickly detect and resolve faults.

Thanks to advances in numerical control technology, self-diagnostic capabilities are becoming increasingly sophisticated. For example, the A-B10 system has specialized diagnostic software that can be connected to a network for remote diagnosis.

2. Practice more, cultivate your practical ability and master experimental skills

Sometimes faults can appear ambiguous and it can be challenging to determine whether the problem is electrical or mechanical in nature.

For example, the Coburg gantry milling machine encountered such a fault, where regardless of whether the z-axis is being raised or lowered, the z-axis ram always moves downward and triggers an alarm.

We employ the “separation method” to solve the problem. This method completely isolated the electrical component control from the original circuit. We disconnected the DC motor wiring terminal from the z-axis and connected the DC power, which was derived from the 220V AC power supply through four-diode voltage regulation and rectification, to the two ends of the motor.

In doing so, we discovered that the electrical function changed the direction of rotation based on the conversion of polarity to DC power, effectively eliminating the electrical fault.

Upon further inspection, we discovered that the failure was actually caused by the mechanical friction plate slipping and the ram sagging.

There are several other methods such as “isolation method”, “replacement method”, “comparison method” and “percussion method” which can be used to locate and resolve faults effectively.

3. Practice more and learn to use relevant instruments

There are several tools that can help in judging and checking specific circuits, such as an oscilloscope, multimeter, online circuit detector, short circuit detector, computer, programmer and more. These tools, particularly the PLC programmer and computer, can be especially helpful in these efforts.

Maintenance personnel must be proficient in using these tools and have the ability to enter and generate machine parameters, perform online testing of relevant states, and initiate system initialization.

This experience will greatly help in analyzing failures, especially complex failures, and will enable troubleshooting.

4. Practice more and make “small changes”

When a component such as a toggle switch, button or relay is damaged during normal operation and spare parts are not available, try to temporarily repair it using adhesives or other special methods to ensure that the machine tool can continue to operate until o replacement parts arrive.

For example, the German VDF CNC cart has five miniature pressure switches for attaching to the back of the second knife. If two of these switches are accidentally damaged and spare parts are not available, temporary repair methods must be used.

We used the “short circuit method” to make the pressure switch contact meet the PLC input requirements, allowing the machine to operate normally without any alarm.

Over time, poor machine positioning accuracy may result in a positioning alarm. In these cases, the machine parameters can be temporarily adjusted by increasing the “tolerance” zone, allowing normal operation.

Our years of maintenance experience have shown us that foreign-designed CNC machine tools, especially large ones, are not perfect and often have problems and defects. Through our studies and improvements in CNC machine tools, we have been able to resolve these issues and achieve positive results.

For example, the German VDF CNC cart was originally designed with two static pressure brackets that were always operational, and the static pressure pump ran continuously, consuming electricity and reducing the service life of the imported pump. By adding two switches, we were able to modify the PLC and control the operation of the two static pressure holders, extending the life of the imported pump and saving more than 20,000 kWh of electricity annually.

In another example, the original design of the Ingersoll impeller slot mill only allowed reverse milling with the main and auxiliary heads. However, when machining the impeller of the 20th stage of the high and intermediate pressure rotor, reverse milling was not possible due to the small distance between the impellers. We solved this problem by intelligently changing the bidirectional boundary wiring and adding it to the PLC program, allowing milling in the same direction. This doubled our work efficiency and allowed us to complete the rotor processing task 3 to 4 days in advance.

In conclusion, we must continue to explore the potential of CNC machine tools and fully utilize their capabilities to serve production.

5. Practice more and repair the board yourself

In general, the circuit board of a CNC machine tool is reliable and has a low failure rate. When performing a CNC machine tool check, it is not advisable to immediately suspect a problem with the board.

In the Siemens 850 system, alarms such as 41nc-cpu and 43plc-cpu may occur. These alarms are not necessarily indicative of a circuit board problem.

They can often be resolved through various methods such as repeated testing, removal procedures, NC initialization, PLC cold and hot starts, and others. If the cause is determined to be a problem with the circuit board, it must be repaired.

The circuit boards in this system can be expensive, often reaching thousands or tens of thousands of yuan, and obtaining replacement parts can be challenging for companies. Therefore, the quality of the CNC machine tool circuit board is critical. Any damage to the board may result in production stoppages as spare parts may not be readily available.

In some cases, a small fault on the circuit board may be the cause of an alarm. Careful inspection can often identify such problems as capacitor leaks, improper soldering, or short circuits. Complex faults can also be repaired with the help of instruments, given enough time.

However, some circuit boards, especially large-scale integrated circuits, can be difficult to repair, especially if the original device has no spare parts. In these cases, you may need to purchase replacement boards in advance or send them in for repair.

Self-healing circuit boards offer several benefits to businesses. It can save costs and provide a quick solution to urgent problems. Additionally, it can provide an opportunity to gain deeper knowledge and experience with electronic circuits, which can improve analytical judgment and practical skills.

Conclusion

While CNC machine tool failures can be complex and constantly evolving, taking a serious approach and cultivating a high-quality electromechanical integration maintenance team can help. By observing more, asking more questions, thinking more critically and gaining more hands-on experience, this team can accumulate knowledge and skills to repair, use and manage CNC machine tools effectively. With dedication and perseverance, trusting your own strengths becomes possible.