1. Main uses and characteristics of CNC turret punch

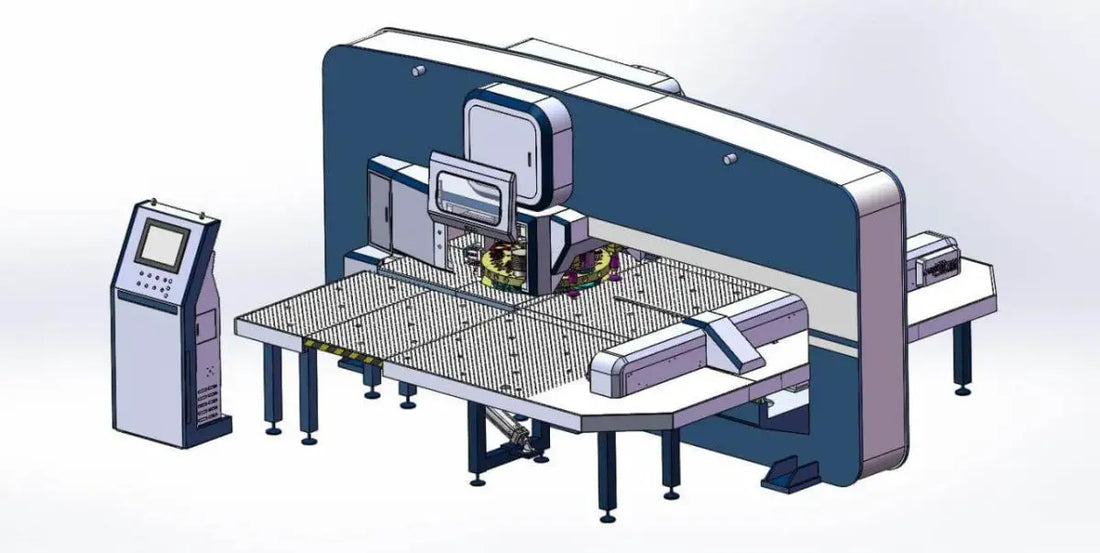

The CNC turret punch is a highly efficient and precise sheet metal processing equipment controlled by a CNC system. It is one of the most practical integrated machines that combines electrical and hydraulic components in pressure processing equipment.

The CNC turret punch can automatically perform a variety of complex and shallow deep drawing molding processes in a single operation. Plates can be precisely positioned in the X and Y directions through automatic programming, and molds in the rotary table mold library can be automatically selected for processing based on requirements.

Small punching dies can also be used to create large round, square, waist and curved contour holes of various shapes through step punching. Special processing techniques such as louvering, shallow stretching, counterbores, flange holes, reinforcements and embossing can also be carried out.

2. Use CNC turret punch requirements

1. Operating environment

To extend the service life of the CNC turret punching machine, it is generally recommended to maintain a moderate ambient temperature. Avoid exposing the machine to direct sunlight or other sources of thermal radiation. It is also important to place the machine in an environment free from excessive moisture, dust or corrosive gases.

Also, keep the CNC turret punching machine away from electromagnetic and high-frequency equipment such as hydrogen arc welding machines and electric welding machines.

2. Power Requirements

Special power lines are typically used to supply power to the CNC turret punching machine. To minimize fluctuations and high-order harmonics in the power grid, three-phase AC voltage stabilization devices are generally installed to reduce the impact of power supply quality and electrical interference.

The starting end of the power supply must be properly grounded. The CNC turret punching machine must be connected to a three-phase five-wire power system, with the neutral line (N) and ground (PE) kept strictly separated. It is also important to ensure that protective earthing is installed correctly.

3. Operating procedures

In the operation and management of the CNC turret punching machine, it is important to establish practical and effective operating procedures. This may include regular lubrication and maintenance, reasonable use and the implementation of a standardized change system.

Following these operating procedures is a critical step in ensuring safe operation of your CNC machine tool. Experience has shown that many failures can be avoided by following established operating procedures.

4. Personnel Requirements

The CNC turret punch operator must undergo special training and qualifications before operating the equipment to prevent damage to the machine tool and ensure personal safety.

There have been numerous examples of the consequences of untrained operators, which should serve as a reminder of the importance of proper training.

Personnel operating the equipment must be experienced, qualified and familiar with the condition of the equipment to ensure its stable operation.

5. Routine maintenance

Carrying out daily maintenance on the CNC punch can help maintain its good condition and extend its useful life. This routine maintenance can also identify and resolve potential problems before they cause significant damage or loss.

6. Dynamic storage of numerical control equipment

After purchasing the CNC turret punch, it is important to make the most of it, especially in the first year of operation, to identify any weak points that could cause problems. These problems must be resolved within the warranty period.

When not in use, it is recommended to turn on the CNC turret regularly, preferably once a week, to reduce the humidity inside the machine by utilizing its own heat. This will prevent moisture from affecting the electronics and detect any insufficient battery power alarms in a timely manner, preventing the loss of system-defined parameters.

3. CNC turret punch maintenance

(1) Maintain a clean and orderly environment around the machine tool. Regularly clean the surface of the machine tool to remove oil stains and keep the bench free of debris. Clean moving surfaces such as lead screws and guide rails once a week. Immediately remove debris from around the turntable to prevent scratches, material build-up and collisions.

(2) Properly lubricate the machine tool and make sure all lubrication lines are unobstructed. Regularly inspect the centralized lubrication device and hydraulic station to ensure that the oil level is adequate and the oil quality is good. Drain the air compressor and water distributor equipped on the machine tool daily, and check the oil level of the oil mist to ensure sufficient lubrication for the air piping.

(3) Regularly inspect the molds to avoid damage due to wear of the die opening or guide key.

(4) Do not press the “emergency stop” button unnecessarily, especially when using the rotary die.

(5) Do not manually pull the rotary die synchronous belt to avoid misalignment of the C axis.

(6) Check the electrical panel components for dust, especially those with cooling fans, and clean them at least once a month. Keep the electrical control cabinet dry and clean.

(7) Check hydraulic and pneumatic components for oil and air leaks.

Daily maintenance and upkeep:

- Tower punching machine equipment must not be exposed to rain, collisions or severe vibrations during transportation, installation and use.

- Pay attention to the timely removal of turret press drilling debris and corrosive dust:

2.1 Immediately remove waste from the waste cart located at the bottom center of the main unit. Avoid accumulation of waste above ground to avoid interference with the movement of related components.

2.2 Regularly clean the corrosive dust on the guide rails of moving parts and transmission parts (such as ball screws) to prevent damage to the surfaces of the parts. - Tower punching machine maintenance:

3.1 After the equipment has operated for 500 hours, retighten all connecting fasteners (screws, nuts, etc.) and check them regularly afterwards.

3.2 Before each shift, inspect the hydraulic station and check the sensitivity of the electrical limit switches. Make sure there is no debris in moving parts and material chutes. - Turret punch press rust prevention:

4.1 Apply a layer of oil film to exposed smooth surfaces (such as guide rails and ball screw surfaces) for lubrication and rust prevention.

4.2 When the equipment is not used for a long period, coat metal surfaces with anti-rust grease. - Strictly and meticulously lubricate the turret punch: see the lubrication section for details.

- Turret punching machine lubrication instructions:

6.1 Oil cups are present in the flange covers of the ball screw nuts and linear sliders; apply oil once a month.

6.2 The bearings of each drive shaft and ball screw are lubricated during machine assembly. Lithium-based grease must be added during major overhauls or intermediate maintenance (with a use interval of no more than three years).

6.3 Before starting the machine, check whether the oil level is normal, whether the filter indicator is within the green zone, whether the connection is firm and whether there are any loose or abnormal components.

6.4 During machine operation, constantly monitor pressure, temperature, noise, hydraulic oil quality and system leaks. The oil temperature should be in the range of 35-55°C and should not exceed 60°C.

6.5 Regularly inspect and replace components as necessary:

– 6.5.1 Inspect oil filters, air filters and connection fasteners monthly to check that they function correctly.

– 6.5.2 After using new oil for 400-500 hours, collect a sample for testing. Replace the oil with qualified oil every 3,000-4,000 hours, and test the new oil after 1,000 hours of use.

– 6.5.3 In addition to constantly monitoring pressure changes in the accumulator (using as a reference the sudden change in pressure gauge readings when the pump stops), check the nitrogen gas pressure inside the accumulator monthly.

– 6.5.4 Inspect components such as oil pumps and valves every six months to ensure normal performance.

4. Typical fault analysis and troubleshooting of CNC turret punch

1. Strip failure

The punch may not retract from the sheet when the die rises, or the die may rise with the sheet, due to lack of material return force or inadequate timing during continuous stamping.

Reasons:

- Spring fatigue

- Inadequate time during stamping

- Upper cutting edge wear due to melting

- Inadequate release

- Poor mold lubrication

- Lower cutting edge wear

Measurements:

- Replace the spring

- Adjust step length

- Avoid melting and burning of the upper mold and rotate or change the punch material

- Choose the mold with proper clearance based on the board thickness and material to ensure proper alignment during blanking

- Clean the mold regularly and maintain adequate lubrication

- Regularly sharpen the lower die and maintain a small arc at the right angle of the blade.

2. Waste recovery failure

During the punching process, the upper die removes the blank from the lower die after the hole is punched.

Reasons:

- There is oil on the upper surface of the plate or the lower surface of the die, causing the residue to stick to the punch, resulting in its lifting;

- The mold (or sheet) is magnetic;

- High stamping speed and fast return stroke create an air cushion effect;

- The previously removed residual material is trapped in the lower die, creating an airtight cavity, and the residual material returns;

- Incorrect mold height;

- Opaque mold;

- Large die backlash value;

- Aluminum sheet or stainless steel sheet with film;

- Aged or damaged unloader bar.

Measurements:

- Remove oil stains on the surface of the plate and replace the rubber column at the end of the punch in a timely manner;

- Completely demagnetize the matrix after grinding;

- Adequately reduce the number of stampings;

- Increase the modulus accordingly, typically to 1 mm or more;

- Check the vacuum system if a vacuum suction device is available;

- Keep the edge of the mold sharp by sharpening it in a timely manner;

- Choose the bottom mold with adequate clearance;

- Use the bottom mold to prevent residue from jumping out.

3. Rotary table displacement failure

When the CRT sounds an alarm indicating that the T-pin is not in place or that the pin is missing, the rotary table experiences vibrations.

Cause:

After a period of use, the rotary table positioning pin may dislodge from the positioning hole due to chain deformation or other factors. This may result in misalignment of the upper and lower rotary tables or just one of the rotary tables.

Regardless of the situation, the adjustment process remains the same.

Adjustment method:

- Turn on the machine.

- Put the machine in manual mode.

- Press the “Pin Out” button to release the positioning pin.

- Loosen the bolts securing the driveshaft sprocket end cover, allowing the driveshaft and sprocket to rotate relative to each other.

- Manually move the rotary table to align the positioning pin with the positioning hole on the rotary table.

- Press the “Pin In” and “Pin Out” buttons repeatedly to verify that the pin is aligned with the rotary table. Once the adjustment is made, secure the pin.

- Before making any adjustments, check the chain tightness. If the chain is loose, tighten it before aligning the positioning pin.

- When both sides of the chain reach a similar tension, secure the sprocket clamping sleeve.

- Finally, go back to automatic mode.

4. Hydraulic system failure

In the case of a 1050 alarm, the punch is not at top dead center and the X-axis, Y-axis and T-axis are unable to function. This occurs on the VT-500 model with a FANUC Oi-P CNC system and a Rexroth hydraulic system.

Upon encountering this fault, a review of the technical maintenance data only reveals that the main hydraulic pump is not activated, without any additional warnings. However, the oil pump has been functioning normally.

The hydraulic system has a known problem with high oil temperature, and the 4WRSE servo valve temperature is also high.

It is possible that the servo valve is defective. However, because the valve is difficult to inspect without disassembling it, it is challenging to determine its condition.

Troubleshooting steps:

- Check that the voltage at both ends of power supply A and B of the intermediate servo valve is 24V, and check that the servo valve plug is securely connected and that the operation light and power light on the HNC control card are lit normally.

- When the oil pump is turned on, the punch should move a few millimeters and the oil pressure should vary within the set values.

- Make sure the data bus plug between the HNC control card and the CNC system is connected correctly. If necessary, open the plug and inspect the wiring.

- Check the top dead center PTE signal by entering the self-diagnosis function (corresponding SYSTEM/PMC/PMCDGN/STATUS/X8, X8.2 input must be 1).

- Check that the HNC100 signal voltage between wire numbers 411 and 100 is DC24V, and between wire numbers 612 and 100, the voltage should also be DC24V.

- If no problems are found after the above inspection, please use Win-ped5.05 software to connect to the HNC control card for further diagnosis and check various parameters.

- If no problems are detected, the servo valve may have a mechanical failure and you can replace the valve for testing. If the problem is resolved, the failure will be considered damage to the servovalve.

- If the issue cannot be resolved after following these steps, it is recommended that you contact the manufacturer for assistance.

5. Faults related to punch vibration

(1) During the stamping process, if the pressure stops, the system will automatically restart and can work normally again.

This failure occurs repeatedly during the stamping process without any warning warning, making it difficult to determine the cause under normal conditions.

In most cases, this failure is related to vibration.

If the three-phase voltage is stable, it is usually because there has been an instantaneous short circuit to the DC24V voltage of a valve or induction switch, causing a voltage drop and resulting in the system restarting.

Due to the rapid stamping of the CNC punch, high-frequency vibration can easily cause damage to the DC24V power line of each valve and induction switch, or cause loose wiring, leading to a short circuit between phases. This problem was frequently encountered during maintenance.

To resolve this issue, maintenance personnel must carefully inspect each component, focusing on the signal lines near the tower.

(2) During the continuous stamping process, it generally stops for about 2 seconds and then continues to work without fault alarm.

This failure is mainly related to vibration, and the probability of occurring increases with the thickness of the punching plate, that is, the greater the vibration, the greater the probability of failure.

After careful observation, it was found that the instrument pointer on the pressure gauge attached to the bed exceeded the set minimum value for air pressure due to the vibration amplitude, causing an instantaneous air pressure alarm and a stop. The solution was to remove the air pressure gauge from the base of the puncture and resolve the failure.

5. Conclusion

Achieving high efficiency and good results with a CNC turret punch depends on the quality of the operators and maintenance personnel, who must have a high sense of responsibility and strong professional ethics.

The operator must have an in-depth understanding of the machine's performance, operate and maintain it in accordance with regulations, and prioritize maintenance, especially cleaning and lubrication.

Maintenance personnel should not only focus on analyzing problems and accumulating experience, but also be dedicated to learning, with a strong aptitude for learning and critical thinking.

When examining the appearance of a failure, they must analyze the possible causes of the problem to quickly identify and resolve the root cause.

They must approach their work with care and consideration, avoiding hasty conclusions and unnecessary replacement of components.

In conclusion, good maintenance is an effective way to prevent failures and is the best approach. Instead of wasting time on repairs, it's better to prioritize preventative maintenance.