1 . Introduction

The use of copper by humans dates back to 10,000 years ago. An artifact – a copper ear plug – dating back to 8,700 years ago was discovered in northern Iraq, and bronze pieces existed in China more than 4,000 years ago, during the Xia Yu era.

The application of copper as a conductor has lasted more than 200 years, since the discovery and application of electricity at the end of the 18th century.

Aluminum, a relatively young metal, was known as “silver gold” in the mid-19th century, more precious than gold, until 1886, when the American scientist Hall independently developed the aluminum electrolytic method, paving the way for the production industrial.

The use of aluminum as a conductor began in 1896, when British Sir William Crookes erected the world's first overhead aluminum stranded wire in Bolton.

In 1910, Hupp of the Aluminum Association of America invented steel-core aluminum braided wire, erected over Niagara Falls. Since then, overhead high-voltage transmission lines have been gradually replaced by steel-core aluminum stranded wires.

Additionally, Western industrialized countries began using aluminum conductors to replace copper conductors as distribution wires in 1910.

Currently, around 14% of aluminum produced worldwide is used as electrical material, with the United States being the leader in the use of aluminum in electrical wires, reaching around 35%.

The amount of aluminum used by China's electrical departments accounts for about one-third of the total aluminum consumption, mainly used for high-voltage transmission, while the proportion of aluminum conductors used in distribution is less than 5%. The use of copper or aluminum as conductors is influenced by historical, national and resource conditions.

In the 1950s, with the price of copper rapidly increasing, the global wire and cable industry proposed replacing copper with aluminum. To achieve the same electrical performance, the cross-sectional area of the aluminum conductor needs to be two levels larger or increase by 50% compared to the copper conductor.

In the 1960s and 1970s, for the same reasons, a proposal was made to replace copper with aluminum. From 2005 to today, the proposal to replace copper with aluminum has been presented again.

With the progress of technology, this time the replacement of copper with aluminum mainly refers to the replacement of copper with aluminum alloy. What is the prospect of replacing copper with aluminum? We need to understand more about the properties of aluminum, copper and aluminum alloys.

2. Comparison of Copper and Aluminum

2.1 Performance comparison of aluminum and copper (20°C)

| Performance | Aluminum | Aluminum | Copper | Copper | |

| Annealed (0) | Difficult (H8) | Annealed | Hard | ||

| Atomic weight | 26.98 | 63.54 | |||

| Density/kgm -3 | 2700 | 8890 | |||

| Resistivity/nΩ·m | 27.8 | 28.3 | 17.24 | 17.77 | |

| Conductivity/%IACS | 62 | 61 | 100 | 97 | |

| Temperature coefficient of resistance/(nΩ·m)·K -1 | 0.1 | 0.1 | 0.09825 | 0.09525 | |

| Tensile strength/MPa | 80-110 | 150-200 | 200-270 | 350470 | |

| Young's Modulus/GPa | 63 | 63 | 120 | 120 | |

| Linear Expansion Coefficient/×10-6K -1 | 23 | 23 | 17 | 17 | |

| Specific Heat Capacity | /J(kg·K) -1 | 900 | 392 | ||

| /J(℃·cm3) -1 | 2.38 | 3.42 | |||

| Thermal Conductivity/W·(m·K) | 231 | 436 | |||

| Thermal Resistance/K·W -1 | 0.491 | 0.259 | |||

| Mercury electrode potential/V | -0.75 | -0.22 | |||

| Brinell hardness | 25 | 45 | 60 | 120 | |

| Melting point/℃ | 600 | 1083 | |||

| Heat of fusion/ × 10 5 J·kg -1 | 3,906 | 2,142 | |||

Note: Data comes from the second edition of the “Aluminum Alloy and Its Processing Handbook”.

2.2 Application of Copper-Aluminium Conductors in Power Cables

From the point of view of cable production standards, all power cable manufacturing follows GB12706.1-2008 “Extruded insulated power cables and accessories with rated voltages from 1kV (Um=1.2kV) to 35kV (Um=40 .5kV): Part 1: Cables with Nominal Voltages of 1kV (Um=1.2kV) and 3kV (Um=3.6kV)”, where the cable conductors are produced in accordance with GB/T3956-2008.

GB/T3956-2008 “Cable Conductors” has explicit regulations allowing the use of the first or second type of metal-coated or non-metal-coated annealed copper conductors, aluminum or aluminum alloy conductors.

Tensile strength and electrical conductivity of electrical aluminum

| Status | σb/MPa | Maximum Resistivity (Ω·mm 2 /m) | Conductivity (minimum) / %IACS |

| 1350-0 | 58.3~98 | 0.027899 | 61.8 |

| 1350-H12 or H22 | 82.3~117.6 | 0.028035 | 61.5 |

| 1350-H14 or 24 | 102.9~137.2 | 0.028080 | 61.4 |

| 1350-H16 or 26 | 117.6~150.9 | 0.028126 | 61.3 |

| 1350-H19 | 161.7~198.9 | 0.028172 | 61.2 |

Note: Data comes from the second edition of the “Aluminum Alloy and Its Processing Handbook”.

2.3 Problems with aluminum conductors in power cable applications

In the sixties and seventies, the global price of copper soared. Due to political factors, copper was regulated as a strategic material and, in the domestic market, aluminum was widely used as the main conductive material for transmission cables.

The policy of “replacing copper with aluminum” has become a common technical policy in the electrical industry, with the use of copper conductor cables requiring reporting applications.

Consequently, all main lines and branches of civil buildings used pure aluminum cables. The disadvantages of pure aluminum conductors (AA1350) are mainly reflected in the following aspects:

(1) Poor mechanical strength, easily broken,

(2) Prone to deformation, requiring frequent tightening of screws,

(3) Easily overheats under overloads, posing a safety hazard,

(4) The problem of transition bonding between copper and aluminum is not well addressed.

These issues are not only faced domestically, but are also prevalent in the global cable industry. However, with the improvement of international relations and the implementation of China's reform and opening-up, we have managed to import a large amount of copper resources from abroad, and the price difference between copper and aluminum has become insignificant, leading to a gradual elimination of the trend of “aluminum replacing copper” in the domestic market.

At the same time, foreign countries have actively developed new aluminum alloy conductors to solve the connection problems between conductors and alloy terminals.

Eventually, the United States and Europe extensively used aluminum alloy conductors in distribution lines.

According to the American National Electrical Code (5) NEC330.14: “Solid conductors with a cross section of 8, 10, 12AWG (equivalent to household sizes of 8.37 mm2, 5.26 mm2, 3.332 mm2) shall be made of AA8000 series electrical materials quality aluminum alloy materials.

Stranded conductors from 8AWG (8.37mm2 household size equivalent) to 1000kcmil (506.7mm2 household size equivalent), labeled Type RHH, RHW, XHHW, THW, THHW, THWN, THHN, Type SE Style service entrance U and SE Style R, shall be made of AA-8000 series electrical grade aluminum alloy conductive materials.”

3. Aluminum alloy conductors

3.1 The Development of Aluminum Alloy Conductors

The rapid development of aluminum alloys used as conductors was triggered by the significant increase in copper prices during the 1960s and 1970s. Within the Aluminum Association alloy designations, the main types of aluminum alloys used as conductors include the series AA1000 (pure aluminum), the AA6000 series and the AA8000 series.

AA1000 series is mainly used for high voltage overhead lines. AA6000 Al-Mg-Si (aluminum-magnesium-silicon alloy) series is mainly employed for high voltage overhead lines and aluminum busbars; Both types of conductors exist in a hard state, with connections achieved primarily through welding.

AA8000 series Al-Mg-Cu-Fe (aluminum-magnesium-copper-iron alloy) represents the true soft aluminum alloy used in distribution lines. The AA8000 series of aluminum alloys obtained numerous patents during the 1960s and 1970s.

| League name | US patent number | |

| ANSI-H35.1 | UN | |

| 8017 | A98017 | …… |

| 8030 | A98030 | 3711339 |

| 8076 | A98076 | 3697260 |

| 8130 | A98130 | …… |

| 8176 | A98176 | RE28419 |

| RE30465 | ||

| 8177 | A98177 | …… |

3.2 The main chemical components of AA8000 series conductors are as follows:

| aluminum alloy | Percentage of chemical composition based on quality | |||||||||

| ANSI | UN | Aluminum | Silicon | Iron | Copper | Magnesium | Zinc | Boron | Others (Total) |

Others (Total) |

| 8017 | A98017 | Residue | 0.10 | 0.55-0.8 | 0.10-0.20 | 0.01-0.05 | 0.05 | 0.04 | 0.03A | 0.10 |

| 8030 | A98030 | Residue | 0.10 | 0.30-0.8 | 0.15-0.30 | 0.05 | 0.05 | 0.001-0.04 | 0.03 | 0.10 |

| 8076 | A98076 | Residue | 0.10 | 0.6-0.9 | 0.04 | 0.08-0.22 | 0.05 | 0.04 | 0.03 | 0.10 |

| 8130 | A98130 | Residue | 0.15B | 0.40-1.0B | 0.05-0.15 | … | 0.10 | … | 0.03 | 0.10 |

| 8176 | A98176 | Residue | 0.03-0.15 | 0.40-1.0 | …… | … | 0.10 | … | 0.05°C | 0.15 |

| 8177 | A98177 | Residue | 0.10 | 0.25-0.45 | 0.04 | 0.04-0.12 | 0.05 | 0.04 | 0.03 | 0.10 |

A: The maximum lithium content is 0.03.

B: The maximum silicon and iron content is 1.0.

C: The maximum gallium content is 0.03.

Note: Data from the Aluminum Electrical Conductor Manual – Third Edition.

3.3 Comparison between AA8000 series conductors and pure aluminum conductors (AA1350).

The addition of copper, iron and magnesium elements plays a crucial role in the alloy:

Copper: Improves the stability of the alloy's electrical resistance at high temperatures.

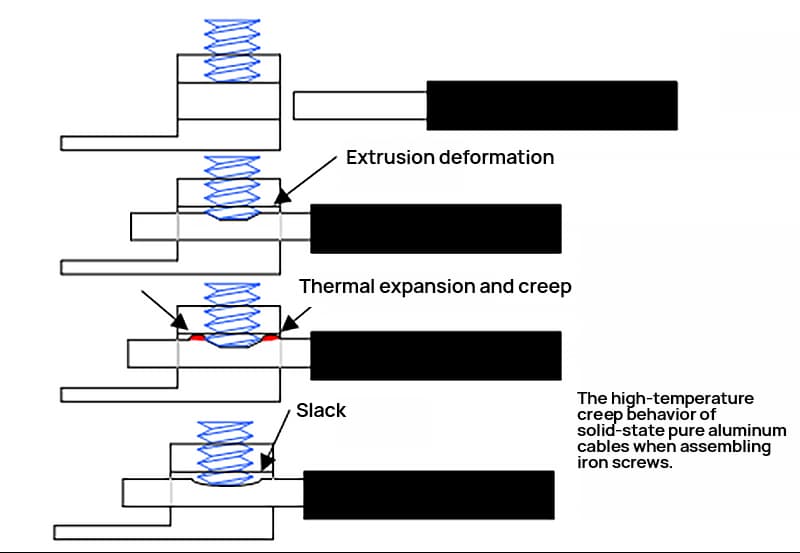

Iron: Increases creep strength and compressive strength by 280%, preventing problems caused by creep-induced loosening.

Magnesium: Under the same interface pressure, it can increase the contact points and provide greater tensile strength.

Performance of Aluminum Alloy for Soft Electrical Wires

| Brand or product name | σb/MPa | σ0.2/MPa | δ/% | Brand or product name/%IACS |

| 1350 | 74.5 | 27.5 | 32 | 63.5 |

| Triple E | 95 | 67.7 | 33 | 62.5 |

| Super-T | 95 | 67.6 | 33 | 62.5 |

| X8076 | 108.8 | 60.8 | 22 | 61.5 |

| Estabiloy | 113.8 | 53.9 | 20 | 61.8 |

| NiCo | 108.8 | 67.7 | 26 | 61.3 |

| X8130 | 102.0 | 60.8 | 21 | 62.1 |

Note: Data comes from the second edition of the “Aluminum Alloy and Its Processing Handbook”.

(1) Mechanical strength: As can be seen from the table, compared with the AA1350 pure aluminum conductor, the tensile strength of the AA8000 series conductor is about 150% of pure aluminum, and its yield strength is about 200 % pure aluminum.

(2) Creep resistance: From the 500-hour creep test, it is evident that the creep resistance of AA8000 series alloy is approximately 280% of that of AA1350 pure aluminum conductor, essentially reaching the same level as the copper.

3.4 Comparison of Aluminum Alloy and Copper Conductors

| Driver characteristics | Electrical Copper (Cu) | AA8000 Aluminum Alloy |

| Density (g/mm³) | 8.89 | 2.7 |

| Melting point (℃) | 1083 | 660 |

| Linear Expansion Coefficient | 17*10-6 | 23*10-6 |

| Electrical Resistivity (Ω*mm²/m) | 0.017241 | 0.0279 |

| Electrical Conductivity IACS% | 100 | 61.8 |

| Tensile strength (MPa) | 220-270 | 113.8 |

| Yield strength (MPa) | 60-80 | 53.9 |

| Elongation rate (%) | 30-45 | 30 |

Comparing AA8000 aluminum alloy conductors and copper conductors, we found that due to differences in resistivity, the International Annealed Copper Standard (IACS) values vary.

AA8000 aluminum alloy accounts for 61.8% of the value of copper. When we increase the cross-sectional area of the aluminum alloy conductor by two degrees or raise it to 150% of the cross-sectional area of the copper conductor, its electrical performance falls into line.

In terms of tensile strength, the aluminum alloy conductor is only half that of the copper conductor (113.8 vs. 220 MPa).

However, because the density of AA8000 aluminum alloy is only 30.4% of that of the copper conductor, even when the cross-sectional area of the aluminum alloy conductor is increased to 150% of that of the copper conductor, the weight of the conductor aluminum alloy is only 45% of copper conductor.

This situation provides the aluminum alloy conductor with certain advantages in terms of tensile strength compared to the copper conductor.

The yield strength of the AA8000 aluminum alloy conductor is close to that of the copper conductor, allowing the creep properties of the aluminum alloy conductor to approach those of the copper conductor.

In terms of elongation at break, aluminum alloy conductor and copper conductor are essentially the same.

Due to the different expansion coefficients of aluminum alloy conductor and copper conductor, they are not suitable for direct connection. We guarantee the reliability of your connection through the following methods.

3.5 Connection Reliability

The crimp-type copper and aluminum terminal and GB14315-2008 connecting tube standard for power cable conductors have been formally implemented.

In this standard, the copper-aluminum transition terminal has also been officially incorporated, providing a theoretical basis for connecting alloy cables to copper busbars and electrical equipment.

The main current methods for copper-aluminum transition are as follows:

1) Alloy cable + copper-aluminum transition terminal (the terminal connects directly to the copper bus).

2) Alloy cable + aluminum terminal (when the aluminum terminal and tinned copper busbar are connected, tighten the screws according to the torque values provided by the national standard and add a disk washer to maintain the effective connection of copper and aluminum during thermal expansion and contraction).

3) Alloy cable + aluminum terminal + bimetal washer (the aluminum part of the washer connects to the aluminum terminal and the copper part connects to the copper bus).

All of these connection methods require 1,000 thermal cycle tests in accordance with IEC61238-2008 or GB9327-2008, simulating 30 years of use to ensure the reliability of the cable connections.

Thermal cycling tests conducted by the Power Board of Georgia in the United States and the Shanghai Cable Research Institute show that alloy cable connections are safe and reliable. Data from experimental reports indicate that its reliability is even more stable than that of copper conductors.

4. Copper and aluminum resources

Overview of Copper and Aluminum Resources

According to data from the United States Geological Survey (USGS), the copper content in the earth's crust is less than 0.01%, while aluminum constitutes 7.73%.

Thus, the aluminum content is more than 1000 times greater than that of copper. Based on current consumption rates, with an average annual growth rate of 3%, global copper resources will last another 32 years.

However, considering the current scale of aluminum extraction (around 140 million tons/year), existing bauxite reserves can satisfy the needs of the global aluminum industry for almost 180 years.

5. Conclusion

Given the excellent electrical and mechanical properties of aluminum alloy conductors, they have improved the unreliability of aluminum connections, insufficient mechanical strength and propensity to creep.

These conductors are similar to copper in mechanical performance, and by increasing the cross-sectional area, they can achieve the same conductivity as copper, making them widely applicable in low voltage distribution systems.

The promotion of aluminum alloy conductors in the domestic market can help the country save a significant amount of copper resources, reduce dependence on foreign copper resources, save a substantial amount of foreign exchange, and also provide certain economic savings to users, making installation easier for installers.

With so many advantages, it is reasonable to believe that the application of aluminum alloy conductors in low voltage power cables will become widely accepted. The trend towards replacing aluminum with copper could potentially trigger a transformation in the cable industry.