In 2005, our company acquired a world-class automatic forging production line (Figure 1) from Germany. This production line is capable of high-speed forging and has a capacity of 3,500 tons.

Fig. 1 panorama of 3500t automatic high speed forging production line

The maximum design production rate is 25 pieces per minute.

Feeding, heating, forging and post-heating treatment are all automatically controlled.

The closed forging process is adopted, which involves five steps to obtain the forging conformation: pre-return, upsetting, pre-forging, final forging and punching.

As illustrated in Figure 2, the mold cooling system uses automatic spray technology. The cooling medium is a mixture of water and release agent in a specific proportion.

Fig. 2 Automatic spray cooling and lubrication

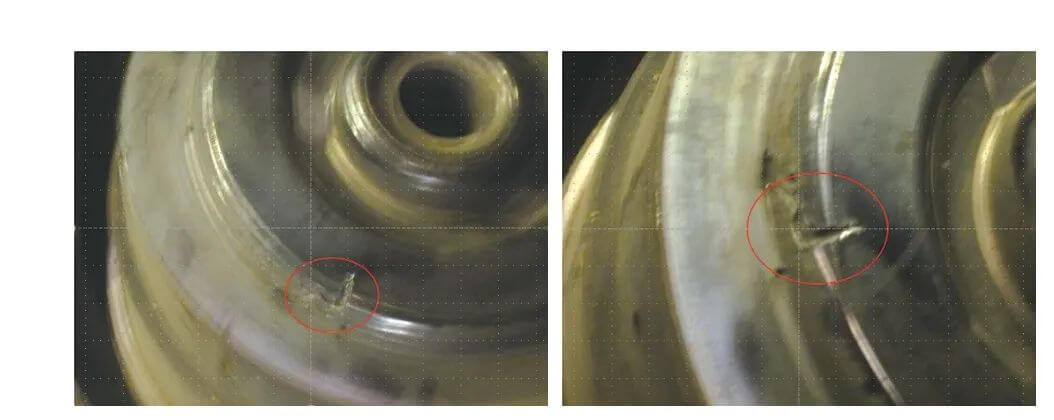

During actual production, it has been observed that certain forging varieties do not reach their normal die life, with the primary form of failure being die breakage (see Fig. 3).

On average, around 1,500 parts are affected by cracks, resulting in approximately 2,500 scrap molds. In more serious cases, around 300 pieces show cracks, leading to the disposal of approximately 1,200 molds.

Fig. 3 position and shape of the mold crack (crack in red circle)

Finding the cause of the failure

The first step involved retrieving the physical and chemical inspection records, as well as the physical and chemical inspection records of the heat treatment of the matrix steel. The hardness of the failed matrix was also checked and no obvious abnormalities were found.

Secondly, careful observation of the shape, size and depth of the crack in the failure mold was carried out in the field. It was discovered that the height of the crack appeared to have been formed gradually by cutting with high-temperature, high-pressure gas.

The third step was to assemble the upper and lower dies of the final forging and pre-forged hot blanks using CAD (as shown in Fig. 4).

Although an enclosed space with a height of about 1.9 mm was present, with an exhaust hole, it was found that die cracking was apparent during actual production. Therefore, it was necessary to analyze this issue carefully using deformation simulation software.

Fig. 4 CAD drawing of upper and lower final forging dies and assembly of hot preforged parts

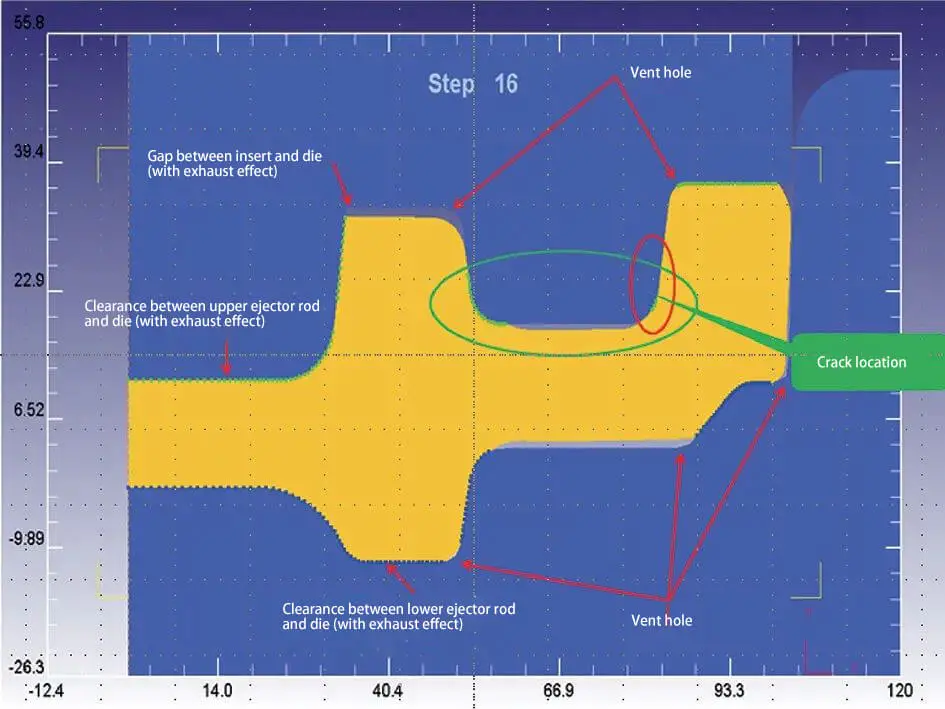

Fourth, using Deformation simulation and careful observation, it was noted that during the final forging forming simulation, in step 16, the arcs on both sides of the upper radii of the final forging die first make contact with the pre-forming blank. hot forged. This results in the formation of an independent confined space between the two nearest exhaust ports on the left and right, as shown in Fig.

Fig. 5 Failure mold deformation simulation (independent confined space in green circle)

After carrying out deformation simulation analysis on several abnormal crack dies, it was found that an independent confined space is formed during the forging process between the hot blank and the two nearest exhaust holes on the left and right of the dies. Superior and inferior. This phenomenon is represented in Figure 6, Figure 7 and Figure 8.

Fig. 6 deformation simulation of failure mold II (independent confined space in green circle)

Fig. 7 Simulation of three deformations of the failed mold (independent confined space in the green circle)

Fig. 8 Deformation simulation of four failed molds (independent confined space in green circle)

The fifth step involves detailed analysis of the information presented above.

The production characteristics of the 3500t automatic high speed forging production line determine that when the slider reaches the top dead center, the spray system will quickly extend to the upper and lower molds of the five steps and apply a significant amount of agent release agent and water mixture over them for about a second.

The timely application of a large amount of coolant (i.e., the release agent and water mixture) serves two important purposes. Firstly, it ensures fast and stable demolding and ejection of hot forged parts, and secondly, it helps maintain the working temperature of the die within a specific low temperature range. This is crucial to prevent the matrix from being damaged due to severe wear or deformation caused by a sudden increase in temperature in a short period of time.

In summary, the timely application of a significant amount of coolant is a crucial measure to ensure the smooth operation of high-speed automatic forging and is absolutely essential.

During forging, the hot blank (which has a temperature of about 1150300 ℃) at high speed. This instantaneous contact can cause the refrigerant to convert into high-temperature, high-pressure gas. However, particularly in an independent confined space, the high temperature and high pressure gas cannot be discharged smoothly through the exhaust hole and eventually acts on the hot mold, causing shear damage.

improvement measures

Based on the results of the above analysis, improvement measures were formulated.

Initially, the previously failed Die I preforging die underwent experimental modifications. The radius surface of the upper final forging die now comes into contact first with the radius of the hot pre-forging blank when placed in the final forging cavity for forging. There is no independent confined space between the two closest exhaust ports on the left and right.

During forging, a large amount of high-temperature and high-pressure gas is generated, which can now be smoothly and timely discharged from the exhaust hole, the gap between the upper and lower ejector rods and the mold, and the gap between the division molds, as shown in Figure 9.

The experimental improvement scheme for the failed Die I proved to be very successful during practical verification. The mold life has now reached 15,000 pieces and there have been no more mold failures.

Fig. 9 simulation of deformation of failed mold after improvement (there is no independent confined space in the green circle)

Based on successful experiences, we sequentially improve other problematic molds. This ensures that when a new hot forged blank reaches the problem stage, there will be no isolated confined space between the blank and the two closest exhaust holes on the left and right sides of the mold. You can find the detailed improvement method in Figures 10, 11 and 12.

Fig. 10 deformation simulation after improvement of failed mold II (there is no independent confined space in the green circle)

Fig. 11 Deformation simulation after improvement of failure mold III (there is no independent confined space in the green circle)

Fig. 12 deformation simulation after improvement of failed mold IV (there is no independent confined space in the green circle)

Improvement effect

The molds, namely I, II, III and IV, were improved individually and the results were highly effective. The average useful life of the molds increased to 15,000 pieces, with no occurrences of crack failures.

In addition to ensuring the appearance quality of forgings, significant cost savings (Table 1) can be observed through reduced die costs. Furthermore, by avoiding the need for subsequent repair of forged parts, unnecessary waste of labor and material resources is also avoided.

Table 1 Improved mold cost savings table

|

NO. |

Forging demand (10,000 pieces/month) |

Mold demand before improvement (piece/month) |

Mold demand after improvement (piece/month) |

Dies safe after improvement (piece/month) |

Cost saved after improvement (10,000 yuan/month) |

Monthly savings (10,000 yuan/month) |

Annual savings (10,000 yuan) |

|

Mold me |

3 |

12~20 |

3~4 |

10 |

4.5 |

18 |

216 |

|

Mold II |

|||||||

|

Mold III |

|||||||

|

Mold IV |

Improvement Summary

(1)To maintain the stable operation of the 3500t automatic high speed forging production line, a large amount of mist coolant must be sprayed. However, when the spray device malfunctions, such as air valve failure (resulting in lack of air for spraying the upper and lower mold) or water valve failure (upper mold spray valve does not spray, lower mold spraying spraying for a long time, or both upper and lower mold spraying for a long period), problems may arise.

In addition, failure of the release agent valve (upper mold spray release agent valve not spraying, lower spray release agent valve for a long time, or upper and lower mold spraying for a long time) may result in water or a mixture of water and release agent remaining in the lower concave of the warm white. This may cause the upper mold not to be lubricated and cooled in time, which causes a rapid increase in temperature. The mold is then more prone to being cut and damaged by high temperature and high pressure gas.

(2) When high temperature and high pressure gases act on a hot die, they may cause cutting damage. This raises the question of why hot forging is not cut, but only the die.

It was later discovered that hot forging, which has a working temperature of about 1150 ~ 1200 ℃, has extremely high plasticity, while the die, with a working temperature of about 200 ~ 300 ℃, does not have the same plasticity .

Both hot forgings and hot dies are subjected to high temperatures and high pressure gases, but the cut line on hot forgings will repair itself due to its high plasticity. On the other hand, the matrix must remain at a relatively low temperature to maintain its hardness, and cannot have any plasticity due to a sharp increase in temperature. As a result, even a small crack caused by high-temperature and high-pressure gas cutting cannot be repaired, and as the forging and forming work continues, the crack will slowly extend and eventually result in the dismantling of the mold.

(3) Practice has proven that this improvement is successful and the effect is very noticeable, which can be considered a cure for the problem.

After a long period of observation and verification, the 3500t automatic high-speed forging production line no longer has die crack failures.

The relevant designers of the forging process room of the hot forming group of the group company's materials physical and chemical center also recognized this improvement and updated drawings were issued.

Conclusion

The successful resolution of the die crack failure problem in the 3,500 ton high-speed automatic forging production line provides valuable information for the die design of the same production line.

After the improvement, the appearance quality of forged parts was improved and there was a significant reduction in die cost.