1. Cone bearing principle

Cylindrical and conical parts can be created by rotating their generatrix, the line that forms the shape, 360 degrees around the center line of rotation within the same plane.

In the case of a cylindrical part, the generatrix is parallel to the center line of rotation, while for a conical part, the generatrix is inclined to the center line of rotation.

The principle of three-point bending is used to roll cylindrical and conical parts.

There are three steps in the lamination process:

1st step:

To start the roll bending process, feed the workpiece into the work roller of the roll bending machine. The roll bending machine consists of three rolls for a three-roll bending machine or four rolls for a four-roll bending machine.

For a three-roll press brake, one roller is located above the workpiece and is called the upper roller, while two rollers located under the workpiece are known as the lower rollers.

In a four-roll press brake, there are three rolls located under the workpiece, with one in the same vertical plane as the top roll, known as the middle bottom roll, and the other two on either side of the top roll, called the top roll. side rollers.

The upper roller of the roller bender can bend the workpiece with any two rollers of the side roller and the middle and lower rollers. This article only covers the symmetrical arrangement of two lower rollers or side rollers and upper rollers.

2nd step:

The second step in the roll bending process is to feed the work roll in a three-point bending motion. In some cases, the top roller is used to press the feed down, while the bottom or side roller moves up.

For descriptive purposes, based on the principle of relative motion, the workpiece and the lower or side roller are considered stationary and the upper roller is pressed downward. When rolling a cylindrical part, the upper roller is parallel to the lower roller while pressing down. When rolling a tapered part, the upper roller is tilted relative to the lower roller during the pressing process.

As the reduction increases, the curvature of the generatrix and its surroundings become greater.

3rd step:

The third step in the roll bending process involves rotating the workpiece through the rotary motion of the work roll. Meanwhile, the reduction of the upper roller is kept constant, making each generatrix of the part have the same curvature or curvature distribution and become a circular cylinder or conical cylinder.

There are many methods for rolling the cone with the plate rolling machine, each suitable for different workpieces and with its own unique characteristics. Regardless of the method used, it is important to ensure that the generatrix of the part coincides with that of the upper roll during the rolling process.

The tapered cylinder is a fan-shaped steel plate wound on the cylindrical work roll plate bender. It is important to ensure that the generatrix of the part coincides with that of the upper roll during the rolling process.

The movement of the fan-shaped steel plate between the work rolls can be considered as a combined movement of the uniform movement of each generatrix point of the workpiece in the direction perpendicular to the axis of the work roll (the rotary movement of the main transmission device of the workpiece). cylindrical work roller can achieve this movement) and the rotation of the workpiece around a vertical line passing through a given point on the generatrix.

To make the large head go faster or the small head slower, an additional moment is applied to the fan-shaped steel plate to overcome the friction between the workpiece and the work roller. This is the key to rolling the cone.

The rotational movement of the part around a vertical line passing through this point on its own generatrix requires the smallest moment.

2. Cone rolling method

Depending on whether the axial roller (block) is used during the rolling process, it can be categorized as axial roller method or non-axial roller method.

There are the following types of non-thrust roller methods:

1) Partition marking method:

To perform this method, draw several generatrices on the fan surface of the workpiece. Then align each generatrix of the workpiece with the generatrix of the upper roller and roll the workpiece on both sides of each generatrix using the generatrix partition.

Although simple, this is an approximate and discontinuous method with low efficiency.

The rotation of the fan-shaped steel plate around the plumb line, which passes through a specific point on its generatrix, is achieved through manual alignment of the generatrix.

2) Cone roller method:

The cone roll method is used for parts with three tapered rolls. The taper of the tapered roller is determined by the workpiece, and there is no slippage between the workpiece and the roller surface.

There are active rollers with tapered rollers (usually top rollers) and passive rollers with segmented sleeves. The workpiece, roll sleeve and roll core slide against each other. As the number of rolls increases, the slip between the part and the sleeve decreases.

The movement of a fan-shaped steel plate is carried out directly through a conical roller. The tapered roller method is the most efficient and economical method, suitable for single variety and mass production.

3) Clamping roller method:

Generally, the clamping roller method is used with a four-roll press brake. To implement this method, tilt the lower roller, clamp the large end of the workpiece with the upper and lower rollers, and adjust the tilt amount and clamping force of the lower roller to suit different workpieces.

The rotational movement of a fan-shaped steel plate around a vertical line that passes through a certain point of its generatrix is carried out by friction between the clamping roller and the surface of the part. Although this method is simple, it requires experience, and when the cone is large or the part is thick, it is often used in combination with thrust rolling.

The non-thrust roller method has the advantage that the plate edge of the workpiece does not contact the thrust roller, and the beveled edge can be made first and then rolled. The integrity of the beveled edge affects the welding quality. The thrust roller method may damage the beveled edge of the workpiece, especially for parts with larger or thicker tapers.

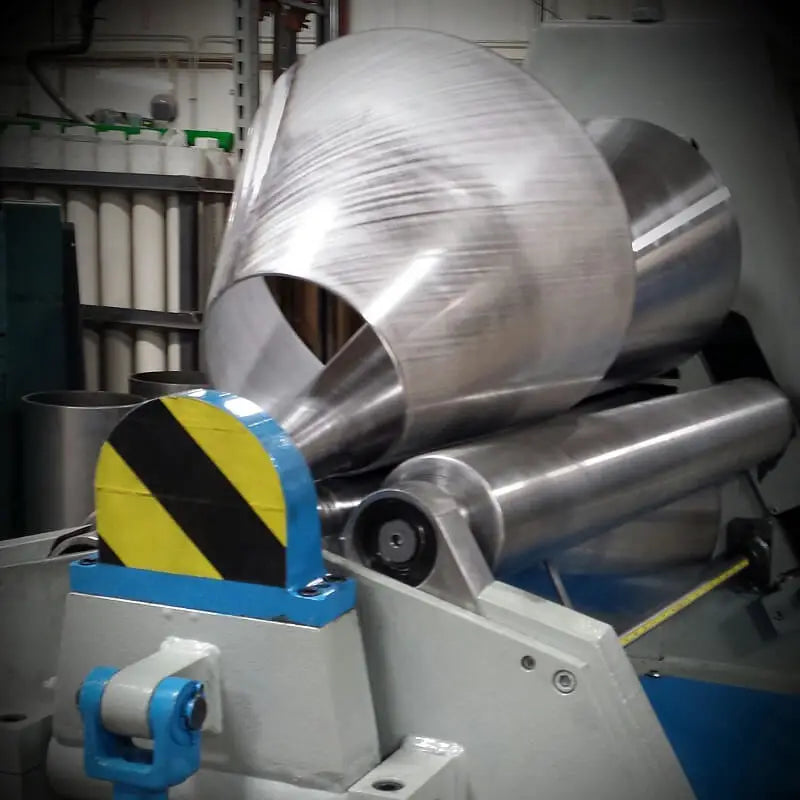

However, creating a beveled edge on a circular part after rolling is very challenging. To make the beveled edge first and then roll the cone, the following winding device is designed on a three-roll plate bending machine with a 70×3500 active roller as the upper roller of the cylinder and cone.

A tapered sleeve consisting of three sections is designed for the upper roller of the wind turbine tower based on the taper of the tower. The tapered sleeve is firmly connected to the upper roller with a key. The conical sleeve has an average thickness of 35 mm and is quenched and tempered. It is dynamically coordinated with the upper roller.

The surfaces of the two lower rollers are tempered, and a small clamping roller driven by an oil cylinder can be placed in the space between the two lower rollers. The clamping roller must clamp the workpiece and the upper roller to prevent the workpiece from sliding with the upper roller. The actual result of the lamination is a 26 mm thick Q345 part. Due to the small taper of the workpiece, a better effect can be achieved without a clamping roller. If the top roller is also hardened, it will be easier to remove and install the tapered sleeve. This is a combination of the tapered roller method and the clamping roller method.

Because the lower roller is cylindrical and the upper roller is covered by a roller sleeve, the structure is simple and the cost is low. There are several types of thrust roller methods:

1) A thrust roller is placed on the upper roller on the overturning side:

The thrust roller is installed in the transition section between the upper roller body and the upper roller tipping side bearing through thrust and radial bearings.

A portion of the thrust roller is inserted into the tipping frame to limit the rotation of the thrust roller with the upper roller.

The thrust roller is generally in contact with the small edge of the workpiece end plate, and the rotational movement of the fan-shaped steel plate around the plumb line passing through a certain point on its own generatrix is carried out by the friction force between the thrust roller and the edge of the workpiece plate.

This method is suitable for workpieces with smaller plate thickness, larger taper and smaller head thrust roller.

2) A thrust roller is placed on the lower roller on the overturning side:

The thrust roller is placed on the two lower roller bearing blocks on the tipping side and is directly fixedly connected to the upper part of the lower roller bearing seat.

The working principle is the same as the first method, which is suitable for parts with a larger cone and smaller head axial roller, and the plate thickness is greater than that of the first method.

3) A thrust roller is arranged on the frame on the facing side:

The thrust roller is installed on the frame on the facing side of the four-roll bending machine with screws, and the upper plane of the thrust roller is slightly higher than the lower generatrix of the upper roller.

4) A thrust roller is arranged on the tipping structure:

Thrust rollers are installed on both sides of the upper roller and the tipping frame, with short sliding keys placed between the tipping frame and the machine frame.

5) A thrust roller is placed on the machine base:

The thrust roller frame is installed on the base with a pin, and the thrust roller is installed on both sides of the roller.

The thrust roller frame can rotate around the pin axis, and the thrust roller can be raised and lowered within the thrust roller frame.

6) A thrust roller is arranged on the transmission side frame:

A large mounting plane is arranged on both sides of the upper roller on the transmission side frame.

The plane has optional internal threads, trapezoidal grooves, pin shafts, keys, etc. for attaching the thrust roller device, allowing the relative position and direction of the gear device relative to the work roller to be changed as required.

All of them are installed at the bottom of the frame. Generally, the workpiece does not interfere with it, and the thrust roller is close to the surface of the work roller.

This method can be used to roll parts with a larger cone and a smaller head thrust roll.

3. Methods for improving cone rolling capacity

Methods 2, 4, 5, and 6 utilize two thrust rollers located on either side of the upper roller.

During operation, the plate is placed against the two thrust rollers, with the feed-side thrust roller exerting torque on the workpiece and the discharge-side thrust roller guiding the workpiece.

Under the force of the thrust rollers, the workpiece will deviate from its original position.

Most of the time, the part is in contact with just one sprocket.

The feed-side thrust roller exerts torque on the workpiece, while the discharge-side thrust roller guides the workpiece. If the workpiece rotates too much around the center line, it will be blocked by the thrust roller on the discharge side.

The two thrust rollers work together to guide and apply rotating moment.

The guiding effect of two thrust rolls is better than that of one, and the rotational torque exerted by two thrust rolls on the workpiece is greater than that of one. However, the two thrust rollers are on either side of the upper roller.

When the workpiece small head thrust roller is small, it is not easy to block the workpiece. When two thrust rollers are used, the workpiece is better guided and can move up and down along its own axis. This results in less wear on the edge of the plate and a longer service life of the retaining wheel surface.

When two thrust rollers are used, the contact between the workpiece and the sprocket creates a more direct and efficient radial force, rather than relying on friction, so there is no need to consider the coefficient of friction.

The further the thrust roller is from the upper roller, the longer the power arm, which leads to greater rotating torque applied. This is illustrated in Figure 1 and Figure 2. The thickness of the rolled tapered tube also requires a larger thrust roller for the small end of the workpiece.

In method 6, there are support blocks at both ends of the thrust roller, making it a simply supported beam with large load capacity. In contrast, in method 5, the retaining wheel is a cantilever beam with a relatively small bearing capacity.

In method 5, the thrust roller is located at the base of the lathe and the workpiece and frame are less likely to interfere with each other.

We use Method 6 on a 55×3200 three-roll press brake to roll a part with a 30-degree half-cone angle.

To avoid interference between the workpiece and the wide frame, a 1 m high support with a large bottom and a small top was added between the thrust roller and the frame mounting plane, and the limiter wheel was inserted into the surface of the work roll along the axial direction.

Sometimes when the workpiece is flat and the thrust roller cannot reach it, the problem can be solved by first bending the workpiece or moving the thrust roller downward.

The disadvantage of the thrust roller method is damage to the edge of the plate at one end of the workpiece.

The thrust roller can rotate around its own axis and move up and down along its own axis, and its surface is tempered to reduce damage to the edge of the plate.

Increasing the distance between the thrust roller and the upper roller can not only reduce the force between the thrust roller and the workpiece, but also increase the force on the thick workpiece, which requires pre-bending the longer end of the plate if possible.

Friction and friction coefficient are very important factors in the cone rolling process.

In the case of the non-axial roller method, a better effect can be achieved without a clamping roller, which may be due to the different friction coefficient between the upper roller and the lower roller.

During rolling of a 40-50 mm thick high-strength steel tapered tube for a large-scale project on a 100 × 4000 three-roll plate rolling mill, all screws for mounting the sprocket to the frame on the side of Transmission were cut off and the project stopped.

According to our field analysis and experience, this may be caused by resonance.

It is suggested to add some lubricating oil between the workpiece and the passive roller to change the friction coefficient and vibration frequency.

This not only solves the problem, but also allows the lamination of thicker parts, as the lubricating oil also reduces the rotating load on the part around the plumb line that passes through a point in its generatrix.

It should be noted that the lubricating oil on the workpiece must be removed after winding to avoid affecting the welding quality.

4. Cone rolling force estimation

The amount of force each method requires for different parts depends on experience and rough calculation.

From the above analysis, it can be seen that there is only one thrust roller to apply the rotating moment to the workpiece, and the load cannot be evenly divided between the two thrust rolls.

The 70×3000 sheet rolling mill of a certain unit is used to roll 60×2000 blast furnace cones with method 6. Due to the insufficient strength of the connecting bolts between the upper and lower parts of the transmission side frame, the bolts broke during the rolling process, and the structure connection was improved to complete the rolling successfully.

In method 1, the axial roller mainly depends on the friction between the axial roller and the workpiece. The positive pressure on the axial roller is several times the friction force, and the workpiece is easily damaged during rolling.

Choose the appropriate method based on the workpiece size and different requirements.