The need for straightening

Due to external forces or heating, steel can undergo various deformations. Raw materials such as steel sheets and steel profiles may present deformations such as irregularities, bending, twisting, curling, etc. This makes it a challenge to ensure the quality of marking, numbering, lofting, and part manufacturing and assembly.

Therefore, before the marking, numbering, lofting and forming processes, raw materials with excessive deformations must be corrected.

Reasons for deformation of raw materials

Deformation caused by residual stress of steel

During the steel rolling process, residual stresses can be generated, causing the steel to become deformed. For example, if the roller adjustment mechanism is faulty, the gap between the rollers may become inconsistent when rolling a steel plate. This leads to inconsistent extension of the steel along the rolling direction.

The part with a smaller gap experiences greater extension, while the part with a larger gap experiences less extension, which results in compressive stress in the larger extension part and tensile stress in the smaller extension part.

When steel cools rapidly or for other reasons, this stress remains in the steel and forms residual stress. When subjected to shear, thermal cutting or other factors, residual stress is partially released, causing the steel to become deformed.

Deformation caused by steel processing

In the process of steel processing, the steel may become deformed due to external forces or uneven heating. For example, shearing, gas cutting, or welding of steel plates can result in deformation of the steel due to stresses and variations in heating and cooling.

Deformation of steel due to improper transportation and storage

The raw materials used in cold working of sheet metal are long and large steel sheets and steel profiles. Improper lifting, transportation and storage can cause steel to bend, twist and deform locally due to its own weight.

In short

There are several causes of steel deformation. If the deviation of the steel exceeds the acceptable range, it must be corrected by straightening.

Straightening principle

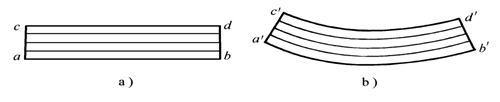

Assuming that the steel is composed of multiple fibers arranged in layers in the thickness direction, when the steel is straight, the length of each fiber layer is equal. However, when steel is bent, the length of each fiber layer becomes unequal.

As shown in the figure, when the steel is straight, the lengths of “ab” and “cd” are equal. However, when steel is bent, the length of “c/d” becomes shorter while the length of “a/b” becomes longer.

Straightening involves using external force or heat to extend the shorter fibers of the steel or shorten the longer fibers. This makes the fibers of each piece equal in length, thus eliminating any uneven bending, twisting, or deformation in the steel or workpiece.

Figure 1

Straightening methods

There are several methods of straightening steel, which can be classified into manual, mechanical and flame straightening, depending on the source and type of external force used.

Common tools for manual straightening – hand hammer

How to use the hand hammer:

Operational requirements:

- Acquire proficiency in the use of hand hammers through appropriate training.

- Be sure to clean any oil residue from the surface and handle of the hammer before using it to prevent slipping and injury to people.

- Check that the handle is securely fastened to avoid accidents resulting from the hammer head detaching.

Hammer

The hammer is an essential tool in cold working of sheet metal, it comes in various shapes and serves different purposes.

(1) Flat head hammer:

It is mainly used to reach flat surfaces and also to reach deeper recesses and edge corners, as shown in Figure 2-a.

(2) Piercing hammer:

It is mainly used to directly strike arc-shaped components, but it can also function as a prying tool and shim, as shown in Figure 2-b.

(3) Bow hammer:

It is mainly used to mold and produce arc-shaped parts, such as refurbishing or preparing small car axle covers, as shown in Figure 2-c.

(4) Intermediate hammer:

The intermediate hammer is used to avoid direct hammering on the part, as shown in Figure 2-d.

Fig.2 Hammer

(5) Flat head plastic hammer:

It is mainly used for trimming corners of boxes and other parts, as shown in Figure 2-e.

(6) Cross Penetrating Hammer:

It is mainly used to eliminate small holes on the surface of the part, as shown in Figure 2-f.

(7) Other types of hammers:

Depending on the specific needs of the hammering process, the hammer head can be of various shapes, such as rubber, wooden or copper hammers, as shown in Figure 2-g.

Fig.2 Hammer

Correct use of the hand hammer is shown in Figure 3.

Fig.3 Correct use of the manual hammer

1. Manual straightening process

Manual straightening is performed with tools such as a hammer, flat plate, anvil or bench vise. Common manual straightening methods include the extension method, twisting method, bending method and stretching method.

Extension method

The extension method is mainly used when the middle of the sheet is convex and the edges are wavy or warped, as shown in Figure 4.

Figure 4 Stretching method for straightening thin metal plates

Twist method

The twisting method is used to correct the distortion of the strips. In operation, the strips are clamped in a bench vise and twisted back to their original shape with a wrench, as shown in Figure 5.

Fig.5 Twisting the straightening strip

Bending method

The bending method is used to straighten various bent bars and strips that bend in the width direction.

Stretching method

The lengthening method is used to correct a variety of thin strands, shown in Figure 6.

Fig.6 Stretch straightening of straight materials

Straightening the protruding surface:

- Place the convex face of the plate on the platform, holding the plate in your left hand and the hammer in your right hand.

- Start striking around the edge of the sheet and gradually approach the center of the convex surface of the drum, as shown in Figure 4.

- Once the sheet is mostly corrected, use a wooden mallet to make final adjustments and ensure even distribution across the entire sheet.

Edge Warp Straightening:

- Place the corrugated sheet on the platform, holding it in your left hand and the hammer in your right hand.

- Start by striking in the middle of the sheet and gradually work your way outwards, as shown in Figure 7.

- Once the sheet is mostly corrected, use a wooden mallet for final adjustments to ensure even distribution across the sheet.

Figure 7

Diagonal Warp Straightening

Step 1: Place the warped sheet on the platform and hold the sheet with your left hand and the hammer with your right hand.

Step 2: Start tapping along the undeformed diagonal line and then extend to both sides to stretch and straighten the sheet, as shown in Figure 8.

Step 3: After the sheet is almost fixed, use a wooden mallet to make a final adjustment to ensure that the entire fabric is evenly stretched.

Patting and Pushing Sheet Metal Straightening

As shown in Figure 9, use a plug (iron) to hit the plate in order to shorten the protruding part and stretch the tensioned part under pressure, achieving the objective of straightening.

Fig.8 Diagonal warping straightening

Fig.9 Patting and pushing straightening of sheet metal

Straightening deformed convex curvatures

As illustrated in Figure 10, the hammer must be aligned with the center of the upper iron to begin with, and then the straightening process is carried out with the hammer.

Fig.10 Convex curve deformation straightening

The hand holding the hammer should not grip too tightly, but rather rely on the wrist for strength. The percussion speed should be around 100 blows per minute.

Concave surface widening straightening

As illustrated in Figure 11, the jack should be positioned slightly above the hammering point, which is the raised part of the uneven surface.

Fig.11 Straightening of concave surface flare

This allows the plate to be subjected to a force between the head of the iron and the tip of the hammer.

Large Concavity Straightening

As shown in Figure 12, first the central part of the concavity is heated to a hot pink state using a torch, and then the bottom side of the central part is lifted using a top iron, resetting the original concavity.

Then, the hammer and top iron are used together to gradually level the raised part, restoring the original geometric shape.

Figure 12 Large concavity straightening

Straightening of Highly Curved Surfaces

As illustrated in Figure 13, when straightening parts with a large surface curvature (such as a high convex surface) such as a fender, they can be first heated with a flame, then lifted with a top iron, and finally flattened with a hammer. to achieve the original shape.

Figure 13 Straightening high curvature surfaces

Straightening small dents

① As shown in Figure 14, the tip of a pick is used to flatten the depression from the inside out.

Fig.14 Straightening small dents

②As shown in Figure 15, a climbing rod is used to reach into the narrow space and force the depression flat.

This method is generally used to pry door recesses, rear fenders, and other body panels closed.

Fig.15 Use a crowbar to remove the depression

③As shown in Figure 16, the depression is flattened with a depression extractor.

Fig.16 Use a puller to flatten the depression

It is mainly used for closed body panels or wrinkles that are inaccessible from behind.

④ The pull rod is used to level the depression, as shown in Figure 17, the protrusion is lowered by tapping and pulling, and the depression is raised.

Fig.17 Use a pull rod to level the depression

Twisted Flat Steel Straightening

Step 1: Hold the steel flat in the bench vise.

Step 2: Hold the other end of the flat steel with a tenor wrench, force the twisted flat steel in the opposite direction of the twist, as shown in Figure 18.

Fig.18 Use a bench vise to correct distortions

Step 3: After the distortion is basically eliminated, peening is used to correct it.

Step 4∶ When punching, the flat steel tilts, the flat part rests on the platform, and the twisted and warped part extends beyond the platform, as shown in Figure 19.

Figure 19

Step 5∶Use a hammer to hit the part that is slightly bent upwards off the platform, the distance between the striking point and the platform is about twice the thickness of the plate, and move the flat steel to the platform while hitting .

Step 6: Rotate 180° and repeat the same hammering until corrected.

Deformation and straightening of steel angles (Figure 20)

Fig.20 Deformation of the steel angle

Step 1: Place the outer bending angle steel and inner bending angle steel on the cylindrical iron node or platform with holes.

Step 2: Bend the angle outward, pierce the edges of both sides at right angles, pierce from the edge, as shown in Figure 21 (a).

For the internal bending angle, it is necessary to tap the roots on both sides at right angles, as shown in Figure 21 (b).

Fig.21 Straightening steel angles

Step 3: Clamp one end of the twisted angle in a bench vise.

Step 4: Hold the right angle side of the other end of the angle steel with a wrench and force the angle steel to twist in the opposite direction and slightly exceed the normal state of the angle steel, as shown in Figure 22.

Fig.22 Angle steel distortion straightening

Step 5: Repeat several times to basically eliminate the distortion of the angle steel.

Round Steel Deformation Straightening

As shown in Figure 23, the round steel is mainly bent and deformed, and straightening only needs to place the round steel on the platform so that the protrusions are upward.

Fig.23 Deformation straightening of round steel

Use a suitable intermediate hammer to place the steel round bosses, and then tap the top of the intermediate hammer to correct.

Rectangular Frame Straightening

straightening method: A rectangular welded part is shown in Figure 24,

Fig.24 Straightening the rectangular frame

When frame sides AD and BC flex, the frame can be placed on the platform with the outer flange AD facing up. The two ends of side BC are damped and the elevated point E is tapped. If all four sides are slightly curved, the frame can be drilled outward or inward, respectively.

For small errors in size, the frame can be placed and the end of the longer side tapped to shorten the overall length.

If angles B and D are less than 90 degrees, the method shown in Figure 25 can be used to hammer point B to expand it.

Figure 25

2. Mechanical straightening process

Manual straightening is time-consuming and labor-intensive, making it only suitable for small parts. For larger pieces, specialized machines are used for straightening.

Mechanical straightening is carried out by means of a straightening machine that repeatedly bends the steel sheet several times, making the uneven fibers of the steel sheet tend to equality, and finally achieving the purpose of straightening.

(1) Mechanical smoothing of sheet metal parts

Operation requirements:

- Correct use of the leveling roller.

- Level deformed sheet metal parts according to requirements.

- Avoid placing your hands around the roller during operation.

Operation steps:

(1) Mechanical leveling of metal sheets:

Leveling method: As shown in Figure 26, adjust the gap between the rollers to match the thickness of the plate.

Please note that the straightening quality depends on the accuracy of the rollers.

Figure 26 Mechanical Sheet Metal Leveling

(2) Lamination of preformed parts

Rolling method: As shown in Figure 27, first replace the rollers below the workpiece with rollers that have a slightly smaller curvature than the rollers above the workpiece.

Then lift the lower roller using a quick release device and place the workpiece between the rollers. Adjust the lower roller pressure so that the workpiece can slide between the rollers under moderate pressure.

Figure 27 Lamination of preformed parts

Notes: Make sure the workpiece is fully rolled to avoid localized stretching. Use a template to continuously monitor the curvature of the workpiece. After rolling the sheet metal parts in one direction, the workpiece must be rotated 90 degrees. When repeating this process, the lamination lines will cross the original direction, as illustrated in Figure 28.

Figure 28

Lamination method for wavy wrinkles of flat rolled metal sheets:

As illustrated in Figure 29, the direction of movement of the metal plate during rolling should be diagonal to its original direction of movement. Maintain consistent pressure and move steadily to prevent new dimples from forming.

Figure 29

(4) Forming method for large metal sheets

Forming method: As shown in Figure 30, two people are required to hold the part while rolling large sheet metal parts according to the requirements of the part. Then the workpiece must be moved back and forth in the rolling mill as previously described.

Figure 30 Forming method of large sheet metal parts

3.F very bad straightening process

Flame straightening is a method of correcting steel deformation through local flame heating. The process takes advantage of the property of metallic materials to expand and contract with changes in temperature. By heating a specific area with a flame, the new deformation can be used to correct the original deformation.

1. Heating position, flame energy rate and straightening

The effectiveness of flame straightening mainly depends on the location of heating and the flame energy rate. Different heating positions can correct deformations in different directions. However, if the location is chosen incorrectly, it may not only not correct the deformation, but also make it more complex and severe.

two . Heating method

(1) Spot heating: The heated area is circular in shape with a certain diameter range, so it is called spot heating, as shown in Figure 31a.

(2) Linear heating: The heated area is linear within a specific range and is therefore called linear heating, as illustrated in Figure 31b.

(3) Triangular heating: The heating method where the heated area is triangular is called triangular heating, as shown in Figure 31c.

Fig.31 Heating method

3. Flame straightening operation

Flame straightening of convex center piece:

Step 1: Place the metal sheet on the platform and secure it with clips around the entire perimeter.

Step 2: Heat the convex area using spot heating, as shown in Figure 32(a). Alternatively, linear heating can also be used, as illustrated in Figure 32(b).

Step 3: Once straightened, use a hammer to tap the clips horizontally to loosen them and remove the sheet metal.

Fig.32 Flame straightening of the convex center piece

Flame straightening of corrugated edge parts:

Step 1: Fix the plate to the platform on three sides using clips, leaving the side with concentrated wavy deformation unfixed, as shown in Figure 33.

Step 2: Heat the plate in a linear fashion, starting from the flat area on both sides of the convexity and gradually moving up to the convexity, as indicated by the arrows in Figure 33.

Explanation:

The length of the heating line should be 1/3 to 1/2 of the width of the plate, and the distance between the heating lines should be adjusted based on the height of the bulge. Higher protrusions should be spaced less apart, typically 20 to 50 mm.

If the first heat results in irregularities, repeat the straightening process with a second heat, staggering the position of the heat line in relation to the first.

Figure 33 Flame straightening of parts that are wavy at the edges

1comment

Informações preciosas.Muitoobrigado.