Manufacturers in the air movement and ventilation industry require reliable information and reliable metal fabrication to serve a diverse clientele. Precision CNC machining services are essential to producing functional ventilation designs and meeting the critical demands of this industry.

As ISO standards and consumer expectations continue to evolve, industrial HVAC systems must adhere to metal fabrication regulations to ensure safety and comfort. In both residential and commercial environments, such as homes or hospitals, efficient air circulation is crucial. Imprecisely manufactured metals can compromise the design and potentially endanger occupants.

Here's what you need to know to avoid all of this. Additionally, we will discuss the practical uses of metal fabrication for ventilation, explore the most common fabrication techniques , and review the benefits of CNC machining for the industrial HVAC industry.

Metal Fabrication, Air Movement and Ventilation: Making the Connection

An HVAC system is designed to regulate a structure's heating and cooling settings. It consists of several parts, many of which are made of metal. Specific materials help maintain temperature and protect system components, making the role of the metal fabricator crucial in producing the parts needed for each system.

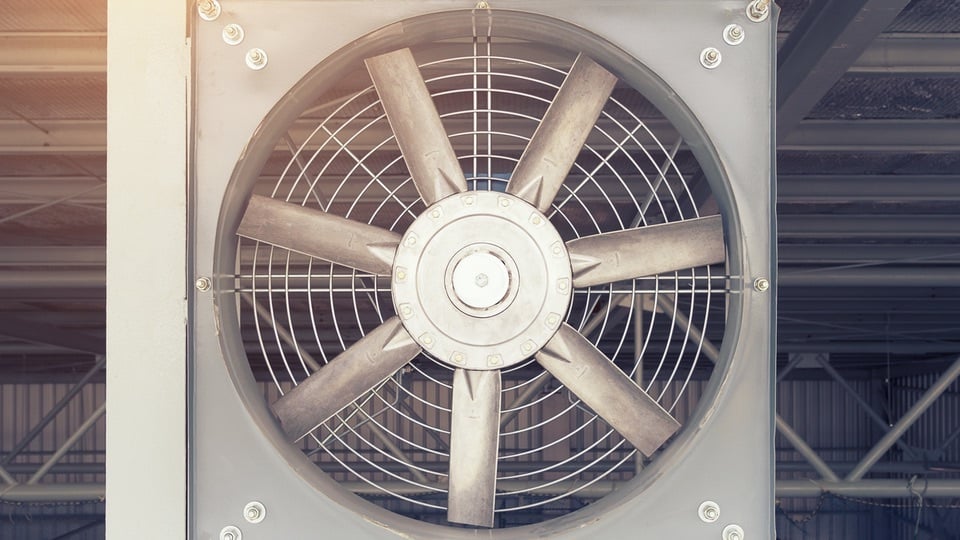

Metal fabrication is critical in creating components needed for residential and industrial HVAC system installations. CNC facilities can manufacture a variety of components, including exhaust fans, panels, fan domes, and ductwork. Air movement, ventilation and sheet metal manufacturing are closely interconnected. Precision metal fabrication ensures a tight fit and consistent insulation, which are vital to passing inspections.

DID YOU KNOW: Precise CNC machining for ventilation components contributes to reducing noise levels and reducing energy waste.

Practical Uses for Metal Fabrication for Ventilation

Manufacturing experts can create a wide variety of air-moving and ventilation components using various materials and techniques. Their catalog typically features these sought-after parts:

- Access ports

- Ceiling boxes

- Floor boxes and registers

- Caps from China

- Elbows

- End caps

- Exhaust fans

- Damping sleeves

- Duct sealants

- Duct Booster Fans

- Flexible ducts

- Flashing

- Fan Panels

- Multiple meters

- hanger straps

- Reducers

- Return air diffusers

- Supply of air diffusers

- Industrial Fans

- Fan domes

- Plenaries

- Pancake candles

- Saddle taps

- Start collars

- Straight boots

- Stackhead boots

- Vent Covers

- Wyes

For a complete list of available industrial HVAC parts, contact your CNC design team.

Metal Techniques and Tools Used in Industrial HVACs

A reliable fabrication shop consistently aligns material and technique to produce functional metal parts for industrial HVAC systems. This is crucial because heat transfer properties can vary depending on the material used, as different materials have varying heat transfer properties. System designs must incorporate components that operate effectively based on their specific applications.

Fortunately, sheet metal fabrication is a relatively well-established process in the air ventilation industry, which has developed standardized practices over time. As a result, HVAC engineers typically utilize similar materials and tooling techniques across multiple projects.

HVAC Metals List

Metal HVAC manufacturers use these materials to produce precision ventilation parts at fast speeds while complying with ISO standards:

- Aluminum: Lightweight and rust-resistant, aluminum is commonly used in ducts, grilles and diffusers due to its excellent heat transfer properties and ease of manufacturing.

- Copper: With its superior thermal conductivity, copper is often used in heat exchangers, refrigeration lines, and cooling coils.

- Stainless steel: Another popular material for its corrosion resistance, stainless steel is often used in areas with high humidity or corrosive environments, such as laboratories or hospitals.

- Galvanized Steel: Known for its corrosion resistance and durability, galvanized steel is widely used in ductwork and other HVAC components.

By using the appropriate materials, metal HVAC fabricators ensure the durability and efficiency of the systems they create. This attention to detail ultimately results in better performance, greater energy savings and a more comfortable environment for end users.

Ventilation Tool Techniques

Industrial ventilation and air movement systems rely on precise manufacturing techniques to make the most of material properties. These are some of the most common tooling techniques used in metal HVAC fabrication:

- Cutting: This process involves dividing large sheets of metal into smaller pieces or custom shapes.

- Prototyping: This step involves creating bespoke components for innovative designs and prototypes.

- Forming: This technique includes bending metals at specific angles.

- Shearing: This method involves cutting long, straight lines into sheet metal to create parts for assembly.

- Punching: This process creates holes in specific locations for aesthetic and functional purposes.

- Stamping: This method forms indentations or recesses in metal parts without piercing the material.

- Rolling: This technique shapes sheet metal and other materials into rounded or curved components.

- Assembly: This step involves joining the formed parts together using methods such as riveting or welding.

Working with a sheet metal fabrication shop offers benefits like rapid prototyping, laser cutting services, and micromachining. It also allows you to design innovative components, test their effectiveness and implement design changes without disrupting the production process.

Four Benefits of Using a Metal Fabricator for Industrial Ventilation

The air movement and ventilation industry benefits significantly from utilizing specialized metal fabrication to create system components. Here are the four main advantages:

#1. Optimized airflow

High-quality metal fabricators build components that promote unobstructed airflow. Their precision designs and machining minimize blockages caused by debris and other potential obstructions.

#two. Consistent Temperature

Regulation Superior metal manufacturing contributes to better control over heat transfer. This results in more stable temperature management in well-sealed HVAC systems.

#3. Extended system lifespan

The use of premium materials and precise manufacturing techniques ensure greater durability, leading to long-term cost savings for businesses and industries.

#4. Compliance with building codes

Expertly manufactured HVAC components adhere to ISO manufacturing standards, making them ready for installation immediately after production and ensuring compliance with building codes.

Develop industrial HVAC systems designed to last with high-quality metal fabrication and premium materials. Reduce production costs, reduce noise production and ensure maximum efficiency with best tooling techniques and a hands-on approach.