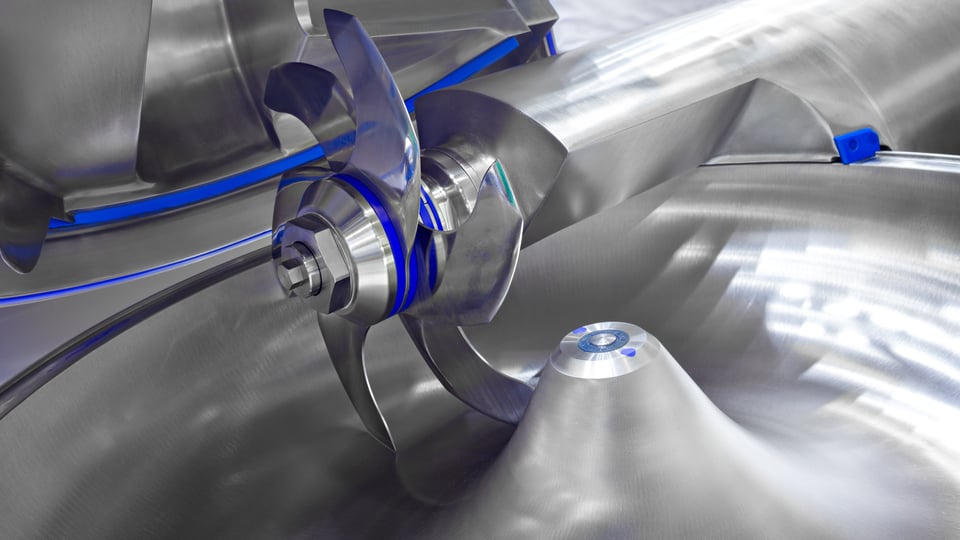

The food and beverage industry relies heavily on high-quality sheet metal manufacturing to produce safe and standardized products. Some food processing facilities require consistent laser cutting services and high-quality stainless steel to provide premium end products. Engineered metals are a key component in everything from food storage equipment and reusable containers to tables and prep utensils.

Without efficient metal manufacturing processes, many popular restaurants may have difficulty meeting consumer demands. Likewise, grocery stores, gas stations and other businesses may face challenges such as failure to comply with industry regulations, which could lead to fines and penalties. The use of stainless steel, rapid prototyping and precision CNC machining is indispensable in today's food and beverage industry.

Are you curious about how machine and parts manufacturing helps support global food production and distribution? This article will explore the various benefits of high precision manufacturing for food processing.

Benefits of Metal Fabrication for Food Production

Equipment used in food processing must maintain sterile conditions, with some components requiring an airtight design. Additionally, food producers and distributors require storage containers robust enough to withstand transportation in various climates. The materials of choice in much of the food and beverage industry are aluminum and stainless steel, both of which must be precisely manufactured to meet certain specifications.

Manufacturing processes allow engineers to develop more durable storage solutions and better food preparation equipment. This not only increases productivity, but also reduces waste and minimizes production costs, making it an invaluable part of the food and beverage industry. Here are some more advantages to consider:

Cost-effective product prototypes

Rapid prototyping (RP) and additive manufacturing (3D printing) allow teams to innovate without compromising quality or extending delivery times. These methodologies can expose design flaws prior to mass manufacturing and distribution, ensuring compliance with rigorous standards in the food and beverage industry. With custom machining and a variety of metal fabrication techniques, producers can bring revolutionary food products to new and existing markets.

DID YOU KNOW? Rapid prototyping can be used to test and evaluate a variety of design concepts before selecting the ideal solution.

Improved product inventories

Companies in the food and beverage industry strive tirelessly to offer products that taste great and stay fresh. However, traditional metal fabrication techniques are not always sufficient to meet regulatory requirements. Combining rapid prototyping with custom machining not only encourages innovation, but also ensures adherence to strict guidelines.

DID YOU KNOW? Supermarkets, which store large stocks of edible products, make up the majority of the food and beverage market.

Satisfied consumers

Consumers in the food and beverage industry will not compromise on quality. They insist on freshness, convenience and value for money. However, advanced metal fabrication services can come with a substantial price tag. Custom machining for food-grade components is indispensable in managing the global economic implications of food production and distribution. This allows manufacturers to meet or even exceed industry expectations without exceeding their budgets.

Improved production quality

Creating better products equals generating higher revenue – a fundamental principle of supply and demand. It is not necessary to increase the prices of your products to increase profitability. Exceptional engineering and manufacturing of metals specifically for food processing can yield a multitude of benefits. This includes earning consumer trust, ensuring retail outlets are eager to stock your products, and helping your business avoid problems like product recalls, liabilities, and legal disputes.

As a member of the food and beverage industry, your fundamental responsibility is to provide safe, convenient and competitively priced products. Using high-precision metal fabrication techniques is an effective way to fulfill this duty. Using advanced methods in metal manufacturing can promote innovation while keeping costs under control.

What can the food and beverage industry do with better manufacturing designs?

Machinery and equipment manufacturing plays an important role in helping producers maintain healthier inventories and exceed market expectations. Techniques such as laser cutting can precisely machine highly durable stainless steel, ensuring impressive precision and consistent quality. This process allows you to prepare, treat and coat food processing products, ensuring that your food grade items not only look attractive but also perform optimally.

Speak with a machinery and equipment manufacturing expert to get detailed information and create a manufacturing strategy that meets your goals. The choice of which will manufacture machines and parts significantly influences the quality of the final product.

The food and beverage industry is responsible for a substantial portion of the world's consumable products. As a result, food manufacturers and processing plants are subject to rigorous industry standards to safeguard public health and safety. Manufacturing high-quality machines and parts plays a key role in ensuring compliance with these standardized methodologies, offering precision and speed.

Concluding

The food and beverage industry, as it seeks to meet increasing demands for the quality and safety of consumable products, crucially depends on innovation and precision in metal manufacturing. The use of high-quality sheet metal and laser cutting techniques ensures the production of equipment and tools that not only meet, but often exceed, stringent regulatory standards. Precision manufacturing of these components ensures that containers, tables and preparation utensils are capable of keeping food safe and uncontaminated during processing and storage.

Additionally, the ability to incorporate rapid prototyping and CNC machining allows for rapid adaptation to new designs and market requirements, minimizing waste and optimizing production efficiency. This capability not only drives innovation in the creation of new products but also solidifies consumer confidence in the integrity of the food and beverages offered.

Therefore, the integration of advanced metal manufacturing processes is vital not only to maintain the competitiveness and economic viability of companies in the sector, but also to ensure that food safety standards are strictly observed. By investing in cutting-edge manufacturing technologies, the food and beverage industry can continue to deliver products that meet consumers' quality and safety expectations, while remaining at the forefront of technological innovation.