Our company has developed a new high-strength nanocement fireproof safety box as part of our scientific and technological achievement transformation project, meeting the needs of our customers.

The safety box consists of an inner container and an outer shell, both folded from cold-rolled steel plates. However, due to the interference between the press brake and the parts, the conventional bending die cannot be used.

The challenge is to find a solution that allows the press brake to bend the U-shaped parts smoothly, without any interference. This is the key to solving the process problem.

1. Parts process analysis

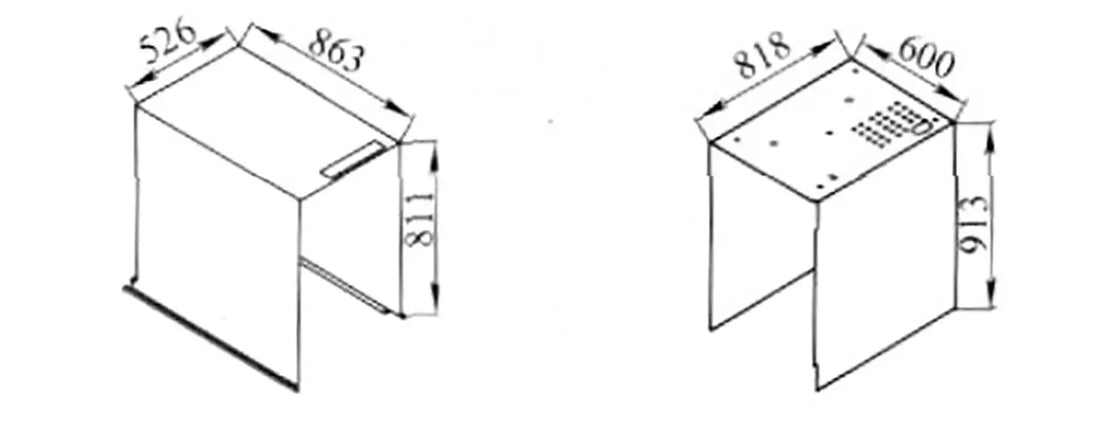

As depicted in Figures 1 and 2, the diagrams respectively show the inner container and the outer casing of the safety box.

Fig. 1 Inner container Fig. 2 Outer lining

The part is manufactured from 3 mm thick cold-rolled steel sheet and requires bending in a press brake. During the bending simulation of the part model, it was found that one of the faces of the part interfered with the machine panel.

After further analysis, it was determined that the aspect ratio of the part was too large, reaching 1.54 and 1.52 respectively, which is significantly greater than the 1:1 aspect ratio. Normally, when bending U-shaped parts using a bending die, the maximum length/width ratio should not exceed 1:1. If the ratio is greater, the long side of the part will interfere with the bending machine, as shown in Figure 3.

Fig. 3 Interference phenomenon on the long side of the part

Related: V and U Shaped Bending Strength Calculator

2. Existing press brake machine structure

We analyzed the bending machine and bending die and found the following:

The front panel of the press brake has a complex and bulky structure, with a thickness of approximately 80mm and is fixed in place. During the bending process, the press brake worktable and the bending die move up and down together.

It was determined that it would be impractical and impossible to modify the bending machine to accommodate the processing of these parts.

However, making appropriate improvements to the bending die design can effectively solve the problem without changing the structure of the bending machine. This approach would allow twice the result with half the effort, allowing for the successful bending of U-shaped parts.

As shown in Figure 4, the conventional bending die has a symmetric structure with an angle of 45°, left-right orientation.

Fig. 4 The common bending matrix

The trajectory of the die is equivalent to the diagonal of a square. The maximum length-to-width ratio of the U-shaped part that can be bent by the die is 1:1. If this ratio is exceeded, one side of the part will conflict with the press brake, preventing successful processing of the part.

3. Solution is interference between the parts and the bending machine

Analysis of the parts process and the structure of the press brake machine's cutting die revealed that the cause of the interference is the high length-to-width ratio of the U-shaped parts, which exceeds the bending capacity of the press brake machine's cutting die.

To solve this problem, we boldly move away from the traditional symmetric structure of the common bending matrix.

We adopt an asymmetric left-right structure as a solution.

In plan view, the U-shaped part is considered a rectangle (see Figure 5). Point A was moved 40 mm (equivalent to half the thickness of the press brake panel which is 80 mm) to point B. The diagonal line between points B and C divides the right angle into two parts, 30° and 60° respectively.

Based on these findings, we designed the upper and lower bending die as shown in Figure 6. The long side of the U-shaped part now avoids the bending machine panel, thus expanding the processing range of the bending machine.

Fig. 5 The plane figure

Fig. 6 The upper and lower bending die

4. Bending die improvement

To solve the interference problems between the parts and the press brake, we made improvements to two different press brakes.

The first improvement was made to the common bending machine. The process involved using the original bending die as a reference, attaching the lower die as a base, and then attaching the newly designed asymmetric lower die over it. Finally, the upper matrix was replaced directly, as shown in Figure 7.

Fig. 7 Improvement on the common bending machine

The second improvement was made to the CNC bending machine. The process involved adding an adjustable lower die bracket that attaches to the base of the press brake. The upper die was then replaced directly, as shown in Figure 8.

Fig. 8 Improvement in the CNC bending machine

The adjustment process for this asymmetric matrix is different from the symmetric adjustment process for the ordinary matrix.

For the common die, only the thickness of the bent parts needs to be adjusted using the tip points of the upper and lower dies as reference.

However, for the asymmetric die, the spacing between the upper and lower dies should be used as the adjustment standard instead of aligning the tip points of the upper and lower dies.

The adjustment process requires first equalizing the spacing between the upper and lower dies on both sides and then adjusting the thickness of the bent parts.

This modification to the original bending die offers lower manufacturing costs, a shorter production cycle and easier operation, resulting in twice the output with half the effort.

5. Conclusion

With the improvement of the bending tool, the problem of interference of U-shaped parts during the bending process has been solved, and the processing capacity of the press brake has been increased.

The operation is simple and easy to use.

For different U-shaped parts, the left and right angles of the bending tool can also be rearranged to solve the interference problem, making it highly valuable for wider use and promotion.