Circuit breaker

A low voltage circuit breaker, also known as an automatic switch or pneumatic switch, is used for infrequent on-off control in low voltage distribution circuits. It can automatically disconnect a faulty circuit in the event of a short circuit, overload or undervoltage and serves as a control and protection device.

There are several types of circuit breakers, including DW frame, DZ plastic shell, DS DC fast, DWX and DWZ current limiting circuit breakers. Each type is differentiated based on intended use and structural characteristics.

The DW frame circuit breaker is mainly used to protect distribution lines, while the DZ plastic housing circuit breaker can be used for protection and control of distribution lines, as well as for motors, lighting and electrothermal circuits.

This article will give a brief overview of the structure, working principle, usage and selection method of molded case circuit breaker as an example.

Circuit breaker structure and operation

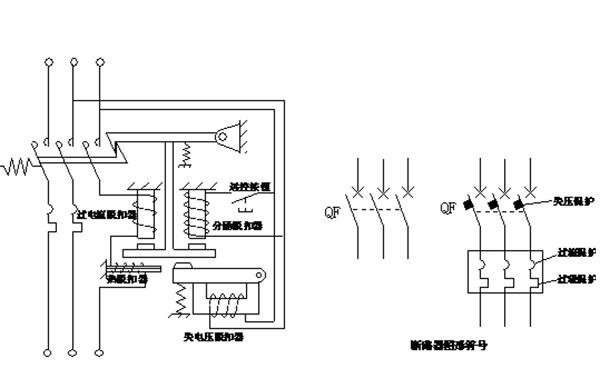

The circuit breaker is mainly composed of three main components: contacts, an arc extinguishing system and various releases, including overcurrent, loss of voltage (undervoltage), thermal, shunt and free releases.

The schematic diagram in Figure 1-8 illustrates the operating principle of the circuit breaker, including its graphic symbols.

The operating mechanism can manually or electrically close the circuit breaker switch. Once the contacts are closed, the free firing mechanism keeps them in the closed position.

The overcurrent relay serves to protect the line against short circuits and overcurrents. If the current in the line exceeds the set value, the overcurrent release generates an electromagnetic force, causing the hook to trip and the moving contact to quickly disconnect under spring tension. This action enables the short-circuit trigger tripping function.

Fig. 1-8 schematic diagram and graphic symbols of circuit breaker working principle

The thermal relay is used for line overload protection and operates on the same principle as a thermal relay.

Voltage loss (undervoltage) release provides protection against voltage loss.

As illustrated in Figure 1-8, the voltage loss relay coil is connected directly to the power supply and is in the “pull in” state, allowing normal circuit breaker closure.

In the event of a power failure or low voltage, the attraction force of the voltage loss release becomes weaker than the reaction force of the spring, causing the spring to push the moving iron core upward and trip the hook, thus disarming the circuit breaker.

The shunt trigger is used for remote triggering and is activated by pressing a remote button, which powers the trigger and generates electromagnetic force to trip.

Proper circuit breaker protection should be selected based on specific needs, and this information can also be indicated on the graphic symbol as shown in Figure 1-8.

The graphic symbol of the circuit breaker displays three protection modes: loss of voltage, overload and overcurrent.

Low voltage circuit breaker selection principle

When selecting a low voltage circuit breaker, the following factors must be considered:

- Circuit Breaker Type Selection: The circuit breaker should be selected based on the application and protection requirements.

- For general use, a plastic shell type can be selected.

- For large short circuit currents, a current limiting type must be selected.

- For high current ratings or selective protection requirements, a frame type must be chosen.

- For DC circuits containing semiconductor devices, a DC fast circuit breaker must be used.

- Nominal voltage and current: The nominal voltage and current of the circuit breaker must be equal to or greater than the normal working voltage and current of the line and equipment.

- Closing and breaking capacity: The limit closing and breaking capacity of the circuit breaker must be equal to or greater than the maximum short-circuit current of the circuit.

- Undervoltage release: The rated voltage of the undervoltage release must be equal to the rated line voltage.

- Overcurrent release: The rated current of the overcurrent release must be equal to or greater than the maximum line load current.

Controller

The Controller is a manually operated device that directly controls high currents (ranging from 10A to 600A) in the main circuit. Some common types of controllers include the KT-type cam controller, the KG-type drum controller, and the KP-type plane controller.

The functions and operating principles of these controllers are generally similar. Taking Cam Controller as an example, it is a large-scale manual controller mainly used to control the starting, stopping, speed regulation, switching and braking of small to medium-sized wound asynchronous motors in lifting equipment. It is also suitable for other applications that have similar requirements.

The Cam Controller consists of contacts, a rotating shaft, a cam, a lever, a handle, an arc extinguishing cap and a positioning mechanism. The structural principle diagram and graphic symbols of Cam Controller are shown in Figure 1-9.

The Cam Controller has multiple groups of contacts that are controlled by multiple cams, allowing simultaneous control of multiple contacts in complex circuits. Because there are many contacts on the Cam Controller, each connection in each position is different and cannot be represented by normal open and closed contacts.

Figure 1-9 (a) shows the schematic diagram of a 1-pole, 12-position Cam controller. The graphic symbol in Figure 1-9 (b) indicates that there are 12 positions for this contact, and the small black dot in the figure represents that the position contact is connected. As can be seen from the schematic diagram, when the crank is turned to positions 2, 3, 4 and 10, the contact is connected by the cam.

Figure 1-9 (c) shows a 5-pole, 12-position Cam Controller, which is composed of five 1-pole, 12-position Cam Controllers. Figure 1-9 (d) shows the graphic symbol of a 4-pole, 5-bit Cam Controller, indicating that there are 4 contacts, each with 5 positions. The small black dot in the figure represents that the contact is connected in this position. For example, when the crank is turned to position 1 on the right, contacts 2 and 4 are connected.

The Cam Controller has a large contact capacity and arc extinguishing device, as it can directly control the motor. Its advantages include a simple control circuit, few switching elements and easy maintenance. However, it also has some disadvantages, such as its large size, cumbersome operation, and inability to be controlled remotely.

Some of the Cam controllers currently in use include the KT10, KTJL4, KTJL5, and KTJL6 series.

Fig. 1-9 Structural principle diagram and graphic symbols of cam controller

Contactor

Contactors are commonly used to control motors, electric heating equipment, electric welding machines, capacitor banks, and other electrical devices. They can cycle AC and DC main circuits on and off frequently to allow remote automatic control.

Contactors have a protection function against low voltage release and are widely used in automatic control circuits of electrical drives. There are two types of contactors: AC Contactors and DC Contactors. The following description focuses on AC contactors.

Figure 1-10 shows the structural diagram and graphic symbols of the AC contactor.

AC Contactor Components

Electromagnetic Mechanism

The Electromagnetic Mechanism is composed of a coil, a moving core (armature) and a static core.

Contact system

The contact system of an AC contactor consists of a main contact and an auxiliary contact.

The main contact is used to open and break the primary circuit and usually has three or four pairs of normally open contacts.

The auxiliary contact serves to control the circuit and acts as an interlock or electrical control. It generally has two pairs of normally open contacts and two pairs of normally closed contacts.

Arc Extinguishing Device

All contactors with a capacity greater than 10A have an arc extinguishing device.

For small capacity contactors, double bridge contacts are often employed to assist in extinguishing the arc.

For large-capacity contactors, a longitudinal seam arc quenching cover and a grid arc quenching structure are often used.

Other Parties

The other parts include a reaction spring, a buffer spring, a contact pressure spring, a transmission mechanism, and a casing, among others.

The contactor is marked with a terminal number, with the coils designated as A1 and A2. Main contacts 1, 3 and 5 are connected to the power side, while 2, 4 and 6 are connected to the load side.

The auxiliary contact is represented by two digits, where the first digit represents the sequence number of the auxiliary contact, and the last digit (3 and 4) represents the normally open contact, while 1 and 2 represent the normally closed contact.

The contactor control principle is simple.

When the coil is supplied with the rated voltage, an electromagnetic force is generated that overcomes the spring reaction force, causing the moving iron core to move downwards.

The downward movement of the moving iron core drives the insulating connecting rod and movable contact downward, thus closing the normally open contact and disconnecting the normally closed contact.

When the coil loses power or the voltage drops below the release voltage, the electromagnetic force becomes weaker than the spring reaction force, causing the normally open contact to disconnect and the normally closed contact to close.

Main technical parameters and types of contactors

Rated voltage

The rated voltage of a contactor refers to the rated voltage of its main contact.

On AC systems, the nominal voltage can vary from 220V to 1140V in special circumstances, with common ratings being 380V and 660V. In DC systems, the most common nominal voltages are 110V, 220V and 440V.

Nominal chain

The rated current of a contactor refers to the maximum current that its main contact can withstand while operating under specified conditions, such as rated voltage, service category, and operating frequency.

Currently, commonly used current ratings range from 10A to 800A.

Nominal voltage of the suction coil

AC 36V, 127V, 220V and 380V, DC 24V, 48V, 220V and 440V.

Mechanical life and electrical life

Contactors are frequently used electrical devices and must have a long mechanical and electrical lifespan, which is an important indicator of product quality.

Rated Operating Frequency

The rated operating frequency of a contactor refers to the maximum number of operations allowed per hour, typically 300 operations per hour, 600 operations per hour, or 1,200 operations per hour.

Share value

The action value refers to the input voltage and the release voltage of the contactor.

It is specified that the contactor must pull reliably when the input voltage is greater than 85% of the rated coil voltage, and the release voltage must not be greater than 70% of the rated coil voltage.

Common AC Contactors

There are several common types of AC contactors, including cjl0, cjl2, cj10x, cj20, cjxl, CJX2, 3TB and 3td series.

Contactor selection

(1) Choose the appropriate type of contactor based on the load characteristics.

(2) The rated voltage must be equal to or greater than the operating voltage of the main circuit.

(3) The rated current must be equal to or greater than the rated current of the controlled circuit.

(4) The engine load should be adjusted as necessary based on its mode of operation.

(5) The rated voltage and frequency of the coil must correspond to the selected voltage and frequency of the control circuit.

Beginner

A starter is a complete set of low voltage control devices used for the starting and stopping control of a three-phase asynchronous motor.

The QJ type decompression starter employs an autotransformer to step down the voltage and is used for infrequent decompression starting control of a three-phase squirrel cage asynchronous motor.

The QX starter, on the other hand, is a delta star step-down starter.

Control circuits for various starters vary depending on engine model and capacity.

Master device

The master electrical appliance is a device used to control the switch contacts in a control circuit, allowing it to perform necessary control tasks.

This device is widely used and comes in a variety of formats, including buttons, limit switches, proximity switches, universal transfer switches, master controllers, selector switches, and foot switches.

Button

The button is a widely used control device with simple structure and easy operation.

Common button structure, types and models

The button consists of a button cover, a return spring, a contact bridge and a housing. Its structure is represented in Figure 1.20, along with its graphic symbol.

The contacts on the button are bridge contacts with rated current less than 5A.

Contacts are further classified into normally open contacts (dynamic breaking contacts) and normally closed contacts (dynamic closing contacts).

Buttons can be categorized based on their shape and mode of operation into flat buttons and emergency stop buttons.

The emergency stop button, also known as the mushroom button, is shown in Figure 1-20 (c).

Furthermore, buttons come in various types such as key buttons, knobs, pull buttons, universal lever types, illuminated types, and more.

Figure 1-20 schematic diagram of the button structure and graphic symbols

The contact action mode on the buttons can be divided into two types: direct action and micro action.

The buttons shown in Figure 1-20 are direct action types, and the speed of contact action is related to the speed at which the button is pressed.

The transformation speed of the contact action of an inching button is fast and is not related to the speed at which the button is pressed. The principle of action is represented in Figure 1-21.

The moving contact in the button consists of a deformed reed. When the curved reed is pressed down and falls below the flat reed, it quickly deforms and bounces the contact of the flat reed upwards, resulting in instantaneous contact action.

A small micro button is also known as a micro switch.

Micro switches can be used in various relays and limit switches such as time relays, pressure relays and limit switches.

Fig. 1-21 Diagram of the principle of action of the inching button

The buttons normally reset and lock automatically.

The most commonly used button is the flat reset button, shown in Figure 1.20 (a).

The button is designed to be flush with the housing to prevent accidental touching of foreign objects.

Button color

The red button is designated for functions such as “stop”, “shut down” and “emergency”.

Green buttons are preferred for “start” or “on” functions, but black, white, or gray buttons are also acceptable.

If a button has a dual purpose, such as “start” and “stop” or “on” and “off”, it should not be red or green, but black, white or gray.

For buttons that activate when pressed and deactivate when released (e.g., “advanced” buttons), black, white, gray, or green buttons are acceptable, with black buttons being the preferred option.

The blue, black, white, or gray buttons must be used for one-time reset functions.

The red buttons should be reserved for those with functions such as “reset”, “stop” and “power off”.

The light button should not be used as an “emergency” button.

Button selection principle

(1) Choose the appropriate control knob based on the application, such as open type, waterproof type, anti-corrosion type, etc.

(2) Based on the intended use, select the appropriate button type, such as key type, emergency type, lamp type, etc.

(3) Determine the number of buttons required for the control circuit, including options such as single button, double button, three buttons, and multiple buttons.

(4) Select the color of buttons and indicator lights based on requirements to indicate working status and conditions.

Table 1-1 provides the meaning of button color.

| Color | Meaning | An example |

|---|---|---|

| Red | Dealing with accidents | Emergency stop |

| Extinguish combustion | ||

| Stop or “turn off” | Normal shutdown | |

| Stop one or more engines | ||

| Local shutdown of the unit | ||

| Turn off a reset switch with “stop” or “off” function | ||

| Green | Start or “turn on” | Normal start |

| Start one or more engines | ||

| Device local home | ||

| Switch on a switching device (put it into operation) | ||

| Yellow | To participate in | Prevent accidents |

| The parameter suppresses the abnormal state | ||

| Avoid unwanted changes (accidents) | ||

| Blue | Any specified intent not included in the color above | All meanings not included in red, yellow and green: blue can be used |

| Black, gray, white | No specific intention | Any function other than the single-function “stop” or “off” button |

Travel switch

A travel switch, also known as a limit switch, has several types. It can be classified into direct action type, micro movement type and rotary type based on its form of movement, and into contact type and non-contact type based on the nature of contact.

Travel switch with contact is simply called travel switch. Its operating principle is similar to that of a button, except that it is activated by the contact action of the moving parts of the production machines, instead of being pressed manually. This switch is used to control the direction, speed, stroke size or position of production machinery and its structure can take many forms.

The principle of action diagram and graphic symbols of various types of travel switch operation are shown in Figure 1-22. The main parameters of a displacement switch include its type, action displacement, working voltage and contact current capacity.

Currently, popular brands of home travel switches include lxk3, 3se3, lxl9, LXW and LX series. Commonly used toggle switches are LX19, LXW5, lxk3, lx32 and lx33 series.

Contactless travel switch

Contactless travel switch, also known as proximity switch, serves as a replacement for traditional contact travel switch and provides travel control and limit protection.

In addition to its use in displacement control, it can also be used in various applications, such as high frequency counting, speed measurement, liquid level control, part size detection and automatic connection to machining programs.

Due to its contactless trigger, fast action speed, flexible sensing distance, stable and reliable signal, long service life, high repeated positioning accuracy and ability to work in harsh working environments, the Contactless Travel Switch is widely used in industries such as machine tools, textiles, printing and plastics.

There are two main types of contactless travel switches: active and passive. Most non-contact trip switches are active, consisting of a sensing element, amplification circuit, and output drive circuit, and typically operate on 5V to 24V DC current or 220V AC supply.

Figure 1-23 presents a structural block diagram of a three-wire active proximity switch.

Proximity switches can be classified into several types based on their working principle, including high-frequency oscillation, ultrasonic, capacitance, electromagnetic induction, permanent magnet, Hall element, and magnetic sensor types.

Each type of proximity switch has the ability to detect different objects. The capacitive proximity switch, for example, can detect solid, liquid or powdery objects. It is composed of a capacitive oscillator and an electronic circuit, with its capacitance located at the detection interface. When an object approaches, it causes a change in the capacitance value, leading to an output signal.

The Hall proximity switch, on the other hand, is designed to detect magnetic fields. It is commonly used with magnetic steel as the sensing body and has a sensitive internal magnetic device that is only sensitive to magnetic fields perpendicular to the end face of the sensor. When a magnetic pole (North or South) is facing the proximity switch, the switch output will be high or low level.

The ultrasonic proximity switch is ideal for detecting hard-to-reach objects. It is not affected by acoustic, electrical, optical or other factors and can detect solid, liquid or powdery objects as long as they can reflect ultrasonic waves. The switch is composed of a piezoelectric ceramic sensor, an electronic device for transmitting and receiving ultrasonic waves, and a program-controlled bridge switch to adjust the detection range.

High frequency oscillating proximity switch is used to detect various metals. It consists of a high-frequency oscillator, an integrated circuit or transistor amplifier, and an output. Its working principle is that when a metal object approaches the oscillator coil, it generates eddy currents that absorb energy from the oscillator, causing the oscillator to stop. The oscillation and stop signals are then shaped and amplified into switching signals, which form the output.

Proximity switches have various output formats, including two-wire, three-wire and four-wire, and their transistor outputs can be NPN or PNP. They come in different shapes, including square, round, grooved, and split.

Figure 1-24 illustrates the working principle of a three-wire NPN photoelectric proximity switch and the working diagram of a remote separation photoelectric switch.

The key features of a proximity switch include its type, action distance range, action frequency, response time, repetition accuracy, output type, operating voltage, and output contact capability.

The graphical representation of the proximity switch can be seen in Figure 1-25.

There are several types of proximity switches, including commonly used household switches such as LJ, 3sg and lxj18 series. Imported proximity switches are also widely used in China.

Contact travel switch selection

When selecting a contact shift switch, the following factors must be considered:

- The application and control object.

- The installation environment, such as open or protective type.

- The voltage and current of the control circuit.

- The appropriate shape of the head, based on the force transmission and travel relationship between the machine and the travel switch.

Proximity switch selection

- Operating frequency, reliability and accuracy.

- Inspection distance and installation dimensions.

- Contact form (with or without contact), number of contacts and exit form (NPN or PNP type).

- Power type (DC or AC) and voltage level.

Transfer Key

The transfer switch is a versatile electrical device with multiple gears, contacts and loop controls. It serves a variety of purposes, including line replacement, remote control, and ammeter and voltmeter measurement in control equipment. Furthermore, it can be used to control the starting, switching and speed regulation of small capacity motors.

The working principle of the Transfer Switch is similar to that of a Cam Controller, but the two are used in different applications. Cam Controller is mainly used to directly control electrical equipment such as motors in the main circuit, while Transfer Switch is mainly used in the control circuit to indirectly control electrical machines through relays and contactors.

There are two main types of transfer switches commonly used: the universal transfer switch and the combination switch. Both have similar structures and operating principles and may be interchangeable in some applications.

The transfer switch is further classified into three types based on its structure: common, open combination, and protective combination. According to its purpose, it is divided into two categories: main command control and engine control.

The graphic symbols used to represent the Transfer Switch are the same as those on the Cam Controller, as shown in Figure 1-26. The on/off state of the transfer switch contact is shown in Table 1-2.

The main specifications of a transfer switch include type, handle type, on/off state table for contacts, working voltage, number of contacts, and current capacity. They are explained in more detail in the product manual.

Commonly used transfer switches include LW2, LW5, LW6, LW8, LW9, LWL2, LWL6, VK, 3LB and Hz series.

The LW2 series is used to control the operation circuit of high voltage circuit breakers, while the LW5 and LW6 series are mainly used to control lines or motors in electrical drive systems. The LW6 series can also be installed in a double column configuration, where the columns are meshed with gears and operated by a single handle.

The switch can be equipped with a maximum of 60 pairs of contacts.

When selecting a transfer switch, it is important to consider the following factors:

- Rated voltage and operating current

- Handle type and placement

- Number of contacts and wiring diagram

- Panel type and marking.

Resistor

Resistance is a crucial electrical component found in various electrical products and can be classified into two types:

The first category is resistance components, used in electronic products with weak current. The second category is industrial resistance devices (commonly called resistors), which are used to regulate low-voltage, high-current AC and DC electrical lines, as well as control the starting, braking, and speed of motors.

The most commonly used resistors are plate resistors ZB and tube resistors ZG, which are used to regulate current in low voltage circuits. The ZX resistor, on the other hand, is mainly used for starting, braking, and speed control of AC and DC motors.

The main technical specifications of a resistor include rated voltage, heating power, resistance value, allowable current, heating time constant, resistance error and overall dimensions.

Figure 1-27 shows graphic symbols for resistors.

Rheostat

The function of a rheostat is similar to that of a resistor, but with one important difference: while the resistance of a resistor is fixed, the resistance of a rheostat can be adjusted continuously. In control circuits, the resistance value can be adjusted by connecting resistors in series or parallel or by selecting different resistance sections. The resistance value is only adjustable in steps.

Common types of rheostats include BC slide wire rheostats, which are used to regulate current and voltage in circuits and control or regulate electronic equipment and instruments. BL type excitation rheostats are used to regulate the excitation or speed of DC motors, BQ starting rheostats are used to start DC motors, BT rheostats are used to regulate the excitation or speed speed of DC motors and the BP frequency sensitive rheostats are used for starting. control of three-phase AC wound asynchronous motors.

The main technical parameters of rheostats are similar to those of resistors. The graphic symbols of the rheostats can be seen in Figure 1-27.

Voltage regulator

There are several types of voltage regulators. TD4 carbon resistance voltage regulator is used to adjust voltage automatically on small and medium-sized AC or DC generators.

Electromagnet

Electromagnets are widely used in various applications. Some of the commonly used types are MQ traction electromagnet, MW lifting electromagnet and MZ braking electromagnet.

The MQ traction electromagnet is used to control mechanical equipment and various automatic systems in low voltage AC circuits. MW lifting electromagnet is installed in lifting machines to attract magnetic materials such as steel. MZ single-phase and three-phase brake electromagnets are commonly used to form an electromagnetic brake.

The schematic diagram of the Tj2 AC electromagnetic brake, which is composed of a brake electromagnet, is shown in Figure 1-28. The electromagnetic brake and motor shaft are normally installed together and connected in parallel. When the electromagnetic brake coil and the motor coil are energized, the motor rotates. However, when there is a loss of power, the brake shoe firmly holds the brake wheel, stopping the engine with the help of a compression spring.

The graphic symbol of an electromagnet is the same as that of an electromagnetic brake and its text symbol is “YA”. Graphic symbols for electromagnetic brakes are shown in Figure 1-28.