Cutting material:

This refers to the process of cutting a rectangular piece using a cutting machine. Numerical control (NC) cutting machines are often used for net size cutting, especially when processing parts with lower demands. Most process engineers use cutting machines to reduce processing costs.

CNC punch:

This refers to using a CNC punch press for drilling. The process involves first scheduling, calculating material usage and discharge, and then processing multiple parts at once.

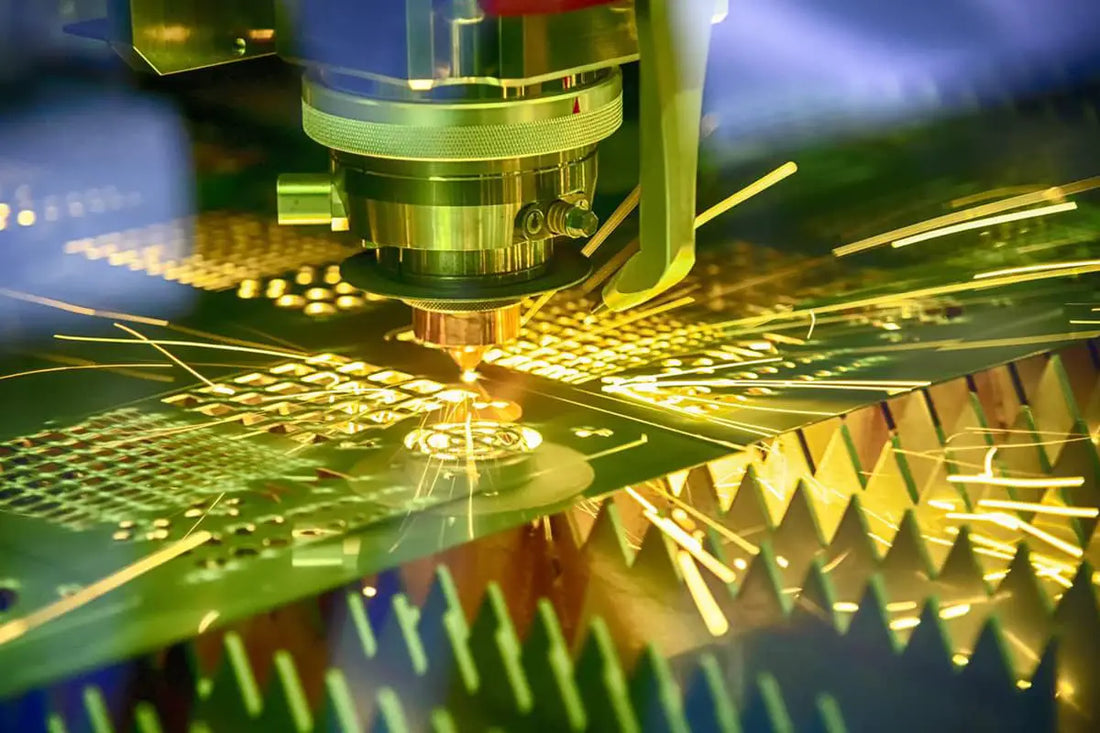

Laser cut:

It refers to the process of cutting a part using a laser. Although the processing cost is high, process engineers should use this technique sparingly.

Cutter suppression:

This refers to the process of using an electric cutting machine with a grinding wheel for cutting. This method is used for processing parts with lower demands, mainly for processing steel profiles. However, there are certain processing safety risks involved, so process engineers should use this suppression method with caution.

Sawing Material:

It refers to the process of cutting material using a saw. It is a low-requirement process, mainly used for cutting steel profiles.

Suppression:

Refers to the process of molding a product using a mold on a common punch or other punching equipment.

Drilling:

This refers to the process of making holes in a workpiece using a common punch and die.

Flexion:

This refers to the process of forming a part using a press brake. It involves using a CNC bending machine and corresponding bending dies to complete the bending process. Before production, there must be a commissioning and inspection step, and if there are special needs, process engineers must explain them first.

Foldable Drilling:

It refers to the process of bending small parts and simple parts using special molds on a common punching machine.

Forming:

Refers to the process of deforming a part using a mold on a common punch or other equipment.

Drilling:

Refers to the process of forming round hole flanges on a workpiece using a die in a common punch or other equipment. Careful specifications about opening and quantity should be added when manufacturing, and the common punch can be equipped with a special die to increase the threading thickness.

Drilling:

Refers to the process of drilling using a drill. When it is not convenient to use a CNC punch or an ordinary punch, drilling can be used to process small quantities manually. The process involves drawing a line and positioning the drilling point. Process engineers should use this method sparingly.

Plate drilling:

This refers to the process of drilling a plate using multiple punches and then conducting batch drilling using a positioning method.

Playing:

Refers to the process of processing internal threads on a workpiece.

Broaching:

This refers to the process of machining a small hole into a larger hole using a drill or milling cutter.

Countersink:

This refers to the process of machining a tapered hole in a workpiece to fit a connecting piece, such as a countersunk head screw. This is done using a drill with an appropriate drill head (90 or 120 degrees) and requires an actual matching method using a countersunk screw. Producers must ensure that the surface of countersunk head screws and the surface of the part holes are level.

Pressure riveting:

The process of attaching nuts, bolts, or rivet nuts to a workpiece using a punch press or hydraulic press. The direction of pressure riveting should normally be toward the flash to ensure smooth loading. Otherwise, the producer must report it immediately.

Pink Riveting:

It refers to the process of first pressing the workpiece into a hole and then using a punch or hydraulic press to firmly attach the rivet nut to the workpiece.

Pull the rivet nut:

It refers to a process similar to riveting, using a shot to firmly connect rivet nuts (POP) and other connectors to the workpiece.

Pull Riveting:

The process of joining two or more workpieces together using a riveting gun.

Riveting:

The process of connecting two or more part faces using rivets. If the head is riveted, the workpiece must first be countersunk.

Perforated Convex Hull:

The process of forming a convex shape in a punch or hydraulic die press.

Punch Tear:

Also known as “punch bridging,” it refers to the process of creating a bridge-like shape in a punch or hydraulic press.

Perforation Printing:

The process of using a mold to imprint words, symbols, or other markings on an artifact.

Cutting angle:

It refers to the process of using a mold to remove the angle of a part in a punch press or hydraulic press.

Drilling Mesh Hole:

A hole drilled in a workpiece using a template on a regular or CNC punch.

Leveling:

Refers to the process of creating a level of form.

Drilling:

The process of using a drill bit to make a hole in a part on a drill or milling machine.

Chamfer:

The process of smoothing the sharp corners of a workpiece using a mold, file, grinder, etc.

Calibration:

It refers to the process of using machines to level a part before and after processing.

Return screw teeth:

The process of repairing a screw thread in a part that has advanced teeth.

Paste protective film:

The process of protecting the surface of a workpiece using a thin film that can protect the surface.

Tearing off the protective film:

Refers to the process of removing the surface protective film.

Review form:

The process of adjusting a processed part.

Thermal shrinkage:

The process of shrinking plastic from a part using heating equipment such as a heat gun or oven.

Marking:

It refers to the process of attaching a label to the designated location on the workpiece.

Design:

It refers to the process of using a wire drawing machine and a sand belt to process the surface of the workpiece.

Polishing:

It refers to the process of smoothing the surface of the part using polishing equipment.

Heat treatment:

A process to improve the hardness of the part through special treatment.

Deburring:

It refers to the process of smoothing the edges of the workpiece using a grinder, file or other tools during sheet metal processing.

Argon spot welding:

Refers to the use of an argon welding machine for spot welding, which is applied in processes with high welding quality. Normal welding spacing is about 30 to 50 mm.

Complete argon welding:

It refers to the use of argon welding machine for full-length welding, which is mainly applied in processes that require high quality and should not show any deformation after full-length welding.

Touch welding:

Also known as “spot welding”, it refers to the process of welding the part face to face with a touch welding machine.

CO2 Protection Welder:

Refers to the use of a CO2 gas shielded welding machine for welding operations, which is applied to processes with common welding quality requirements. Normal welding spacing is about 30 to 50 mm.

Complete welder with CO2 protection:

Refers to the use of a carbon dioxide gas shielded welding machine for full-length welding operations, mainly applied in processes that require high quality and must not present any deformation after full-length welding.

Stud Welding:

Also called “seed welding,” it refers to the process of welding studs securely into the workpiece using a stud welding gun.

Welding Grinding:

It refers to the process of smoothing the workpiece using a grinder and a file. A portable electric grinder is used to polish the welded parts. For parts with high electroplating or spraying requirements, a special grinding wheel (sandpaper) with 120 grit must be used.

Pre-treatment:

It refers to the process of cleaning, degreasing and rust removal, as well as increasing the surface coating (such as phosphating film) and cleaning in electrolyte solution after processing sheet metal and before spray painting or powder spraying.

Scraping Ashes:

Refers to the process of repairing the surface of the part using atomic ash, such as welding seams or pits.

Blowing ash and grinding:

It refers to the process of polishing the surface of the workpiece using a grinder or sandpaper after scraping off the dust. It is a type of repair process that involves grinding the surface of the part with a pneumatic grinder, which is normal in filling processes.

Spray paint:

It refers to the process of uniformly spraying paint onto the surface of the workpiece using a specialized spray gun.

Pulverization:

Refers to the process of applying a coating to the surface of the workpiece using a spray gun or disc-type atomizer, which disperses the coating into a fine, uniform mist through pressure or centrifugal force.

Protection of spray-painted strands:

Refers to a type of rubber covering used to protect nuts, bolts and nut bars, as well as thin adhesive paper that is resistant to high temperatures.

Conductive spray protection:

It refers to protecting specific areas with high temperature adhesive paper. If such a requirement is necessary, process engineers must provide special instructions, which will be carried out by the assembly line.

Silk Printing:

It refers to the process of printing text or patterns onto the surface of a workpiece using special ink. The output must be free from defects such as adhesion, organic solvent resistance, chromatic aberration and font after passing a series of inspections.

Electrogalvanization:

The process of depositing a layer of metal on the surface of a part for protection or aesthetic purposes.

Electroplated Nickel:

The process of coating metal on the surface of a part for protection or aesthetic purposes.

Oxidation:

The process of forming an oxidation film on the surface of a part for protection or aesthetic purposes.

Sand blasting:

The process of treating the surface of a workpiece with a sandblaster.

Set:

It refers to the process of joining two or more workpieces together.

Packaging:

The process of protecting a workpiece and making it convenient for transportation.

Positive CNC drilling chart plan:

The surface requirement process figure should be shown as positive and the symmetry part should unify the burr direction. It should not be applied directly as a negative. Monitoring process engineers must improve the situation and report any similar problems in a timely manner during production.

The burr is up and the burr is down:

The amount withdrawn must be specified in the technical requirements.

Press-up riveting and Press-down riveting:

The number of drawings must be specified in the technical requirements.

Sinking into the hole up and sinking into the hole down:

The number of drawings must be specified in the technical requirements.

Schedule:

Refers to the programming software installed on the equipment by the manufacturer. The production order is processed using CAD drawing files on a special computer, and the edge must be formed after cutting, using the shortest possible punching time.

Well Tools:

Refers to a mold plate used for manual punch positioning. The process engineer must consider this in the product manufacturing process.

Welding Tools:

It refers to the technical requirements of welding dimension, angle, position, space size and other technical requirements. The process engineer must consider this in the product manufacturing process.

Conductive spray protection tools:

Refers to methods for splash protection over large areas, such as fixed installations on sheet iron. This is generally applied to workpieces with large quantity.

Mounting Tools/Gauge:

To ensure that the required size is installed correctly and accurately in the assembly, complete inspection of the size and screws must be performed using assembly tools and gauges such as 19 inch hole spacing.

Bending Inspection Tools:

For batch and complex parts, this must be considered by the process engineer in the product manufacturing process.