Construction machines rely heavily on hydraulic cylinders and these cylinders, in turn, rely on seals.

A common type of seal used in hydraulic cylinders is the O-ring, also known as an oil seal, which prevents oil from leaking or flowing.

In this article, we have compiled a list of various types and shapes of commonly used seal rings for hydraulic cylinders.

Fig. 1 Sealing rings.

Commonly used sealing rings in hydraulic cylinders include: dust seals, cylinder rod seals, shock absorber seals, guide support seals, end cap seals and piston seals.

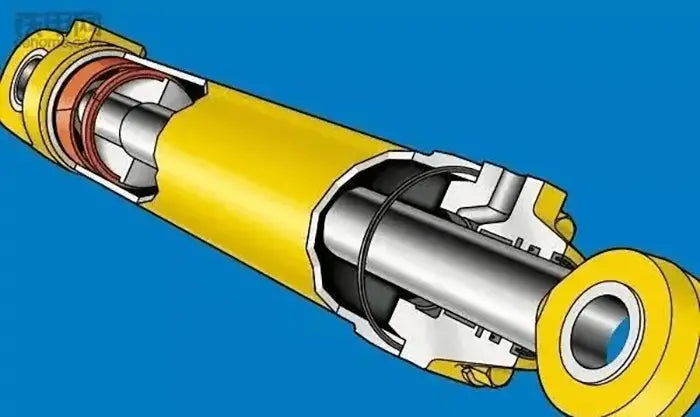

Fig. 2 The position of the different sealing rings.

Basics of Hydraulic Cylinder Seals

In my experience with hydraulic cylinder seals, there are a few important aspects that are important to understand. First, hydraulic cylinder seals are essential components in hydraulic systems. Its main function is to seal the openings between the different parts, preventing fluid leaks and maintaining pressure. Seals can be divided into two main categories: static seals and dynamic seals. I will examine each of these categories and discuss their basic properties.

Static Seals

Static seals are used where there is no relative movement between mating surfaces, such as in flange connections, access covers, or doors. They are designed to prevent fluid leakage and maintain pressure. Some common types of static seals include:

- O-rings: These are the most used static seals, mainly due to their versatility and ease of installation. Made from elastomeric materials, O-rings can be used in a wide range of applications.

- Gaskets: Gaskets are generally flat and can be made from a variety of materials, including rubber, metal, or composite materials. They are used to seal flanges and other static interfaces.

- Metal seals: These seals are made of metal, usually aluminum, copper or steel, and are used in high temperature or high pressure applications.

Dynamic Stamps

Dynamic seals, on the other hand, are used where there is relative movement between mating surfaces, such as in pistons or rods. They need to be more durable and wear resistant compared to static seals as they are subject to constant movement and friction. There are several types of dynamic seals, including:

- Piston Seals: As the name suggests, these seals are used in pistons to prevent fluid leakage between the piston and the cylinder bore. The most common type of piston seal is the U-shaped seal, which features a U-shaped cross section.

- Rod Seals: Rod seals are used to seal the rod-cylinder interface, preventing fluid from leaking along the rod and allowing it to move freely in and out of the cylinder. Wiper seals are a type of stem seal that also helps remove debris or contaminants from the stem surface, keeping the system clean.

- Rotary Seals: These seals are used in applications with rotating components such as motors or pumps. They are designed to maintain sealing even during continuous rotation and can be found in radial and axial forms depending on the application.

Overall, hydraulic cylinder seals are extremely diverse, with several types tailored for specific applications. Understanding the basic principles and differences between static and dynamic seals is crucial to ensuring the smooth operation and longevity of your hydraulic system. The correct seal type depends largely on factors such as application, operating conditions and design constraints.

Types of Hydraulic Cylinder Seals

1. Dust Ring

The dust seal is located on the outside of the hydraulic cylinder end cap and serves to prevent external debris from entering the cylinder.

Based on the installation method, dust seals can be classified into two types: snap-in and press-in.

Fig. 3 Basic shape of the snap-on dust ring.

The most commonly used dust ring is the snap-in type. As the name implies, it fits into the groove on the inner wall of the end cap and is used in less harsh environmental conditions. The material used for the snap-on dust ring is generally polyurethane and comes in different structures such as H-type double lip structure and K sections. Despite the variations, its basic design remains the same.

Fig. 4 Some variants of the snap-on dust ring.

Pressed type dust ring is used in harsh and high stress environments. Unlike the snap-in type, it is not inserted into the groove, but is reinforced with a layer of metal to increase its strength and then inserted into the end cover of the hydraulic cylinder. There are different types of pressure dust rings such as single lips and double lips.

Fig. 5 Press the dust ring and some variants.

2.C cylinder rod seal ring

The cylinder rod seal ring, also known as the U-cup, is the main seal of the piston rod and is installed inside the end cap of the hydraulic cylinder to prevent hydraulic oil leakage. The cylinder rod sealing ring is made of polyurethane or nitrile rubber.

In some cases, it needs to be used in conjunction with a support ring (retaining ring) to prevent the seal ring from extrusion deformation under pressure. There are many variations of cylinder rod seal rings available.

Fig. 6 Common cylinder rod seal ring types.

Fig. 7 Some variants of cylinder rod sealing rings.

3. Damper sealing ring

As an auxiliary sealing ring for the piston rod, the damper sealing ring serves to protect the piston rod in the event of a sudden increase in system pressure. There are three main types of plug seals, including:

Type A: A one-piece seal made of polyurethane.

Type B and Type C: Two-piece seals designed to prevent extrusion and can withstand higher pressures.

Fig. 8 Common types of damper seal ring.

4. Guide support ring

The guide support ring is located on the end cap and piston of a hydraulic cylinder. It performs several functions, including supporting the rod and piston, guiding the linear movement of the piston, and preventing metal-to-metal contact.

The guide support ring can be made of materials such as plastic or bronze coated with polytetrafluoroethylene.

Fig. 9 Guide support ring used in the end cover of the hydraulic cylinder and piston.

5. End cap sealing ring

The end cap sealing ring is designed to seal the joint between the cylinder end cap and the cylinder wall. It acts as a static seal, effectively preventing any hydraulic oil leakage through the gap between the end cap and the wall.

The end cap seal ring typically consists of an NBR seal ring and a support ring, also known as a retaining ring.

Fig. 10 End cover sealing ring.

6. Piston seal ring

The piston seal ring serves to separate the two chambers within a hydraulic cylinder and is considered the main sealing component.

Typically, the piston seal ring is two pieces, with an outer ring made of PTFE or nylon and an inner ring made of NBR. There are several variations of the piston seal ring, including versions made from bronze coated with polytetrafluoroethylene.

In single-acting oil cylinders, a polyurethane U-cup can also be used as a piston seal ring.

Fig. 11 Common piston seal ring types.