A prototyping project is designed to create and model a physical form to test alternative approaches and validate the design. Prototyping in systems analysis and design is repeated many times before creating the final product. We can say, or Wayken can say, that almost every new product needs its prototype examples before being presented to the public.

What is a prototype project?

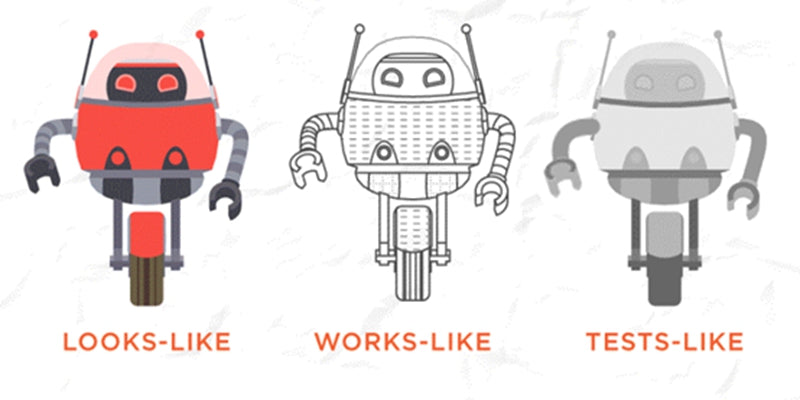

Model prototyping is a system development method in which a prototype is built, tested, and then revised as necessary until an acceptable prototype is achieved from which the complete system or product can now be developed. Although the types of prototyping in different prototyping phases may vary in terms of material, scale and technological applications, evolutionary prototyping can significantly promote the emergence of the new product.

Prototyping techniques can generally be divided into three types: rapid prototyping, CNC machining, and rapid tooling. Due to their unique advantages, each technique is best suited to different situations. They can generally be thought of as three project management steps for prototyping projects.

Three Key Steps to Guide Prototyping Projects

Step 1: Rapid Prototyping

In the early stages of prototyping projects, rapid prototyping through 3D printing is a quick, easy, and cost-effective way to transform design ideas from prototypes into real objects. Prototype models through 3D printing can be used to initially create prototypes to present an object similar to the design. In general, prototype models created through 3D printing are often intended for short-term presentations. For example, designers need the prototype model to present to focus groups and make their design more convincing.

Opting for 3D printing makes sense if developers need:

- A low-cost plastic prototype model;

- Parts with very complex geometry;

- A processing time of 2 to 5 days;

- Special material

Step 2: CNC machining

CNC machining can produce high-precision parts with excellent physical properties directly from a CAD file. Developers undertake editing projects when they need a prototype model of their new design, not only for aesthetic presentation but also for functional testing. Manufacturers like Wayken have 20 years of experience providing CNC prototyping services and are equipped with 3-axis and 5-axis machines. They can provide a combined machining solution for prototyping projects to obtain high-precision parts and save costs.

As a general rule, parts with relatively simple geometry that can be manufactured with limited effort using a subtractive process should generally be CNC machined, especially in the production of metal parts.

CNC offers greater dimensional accuracy and produces parts with better mechanical properties than 3D printing, which can help developers test the functions of their designs. Processing time is usually 2 weeks on short processing times.

Step 3: Quick Tools

In most molds, rapid tooling often serves as a bridge between prototype and production, which in injection molding can be the last step before series production. Speed tools consist of aluminum or carbon steel, a mold base, and hand-loading inserts.

It is suitable when traditional injection molding is prohibitively expensive or unnecessary for the part or volume required. It is therefore a perfect way to minimize costs when a small batch is needed for market testing or when large quantities are not needed in the future.

Wayken offers two rapid tooling injection molding service options – one is better suited for those requiring smaller volumes of parts, often associated with prototyping, and the other is suited for those requiring larger volumes of parts, common in production of small quantities.

On the other hand, the prototype model produced by 3D printing has disadvantages such as limited choice of materials, low strength and poor weather resistance.

This is an aluminum housing prototype design with precision CNC machining. In this case, these aluminum parts with good properties and high precision in functional tests can be used as the final version. Almost all common metals such as aluminum, steel and brass can be processed with CNC tools. There is little difference in machined metal parts between prototypes and formal products.

In addition to CNC machining, the ribs and through hole were machined by wire EDM. Wayken is capable of combining 3- or 5-axis CNC milling with additional processes such as EDM and wire EDM. We can carry out efficient and precise aluminum CNC machining process, especially for typical aluminum surface machining.

Project Management Prototype Examples

-

Example 1: 3D printing prototyping project with SLA

This is a prototype car model used in project presentations, on a reduced scale in relation to the original design. It looks like a new product. Imagine a situation where the designer is in front of a focus group and wants to convince them of the notable advantages of his design over other designs. When he holds a prototype model in hand, he can directly show the audience his design and make it understandable, which gives the audience a deep impression of his talk.

The prototype of the car is made of photosensitive resin, originally beige, and is then finished with glossy paint in some areas and screen printing on the letters and logo. By the way, most of the post-processing of prototypes is carried out manually, which results in relatively high labor costs.

-

Example two: Prototyping project made from CNC machined aluminum

This is an aluminum housing prototype design with precision CNC machining. In this case, these aluminum parts with good properties and high precision in functional tests can be used as the final version. Almost all common metals such as aluminum, steel and brass can be processed with CNC tools. There is little difference in machined metal parts between prototypes and formal products.

In addition to CNC machining, the ribs and through hole were machined by wire EDM. Wayken is capable of combining 3- or 5-axis CNC milling with additional processes such as EDM and wire EDM. We can carry out efficient and precise aluminum CNC machining process, especially for typical aluminum surface machining.

-

Example Three: Prototyping Design for Rapid Injection Molding with Rapid Tooling

This is a prototype design for a car lighting frame. 100 plastic parts could also have been produced using other, more economical manufacturing methods, such as vacuum casting. The reason for choosing fast tooling was that the developer wanted parts that could withstand industrial testing and had properties good enough and close to those of the final products. Furthermore, rapid tooling parts can be produced in a short time and at a relatively low cost compared to traditional molds.

At Wayken, for all rapid injection molding projects, we create the DFM before tooling and provide it to customers to understand the risk analysis and modify the CAD files according to the suggestions. Before parts are produced, we send samples to customers to confirm the quality and start production until the quality is recognized by customers.

If you want to know more about Wayken's prototyping projects, you can contact me at (email protected). I welcome all questions about prototyping projects, not just quotes.