European Standard Designation Systems for Steel Names

1. Designation and meaning of the names of structural steels

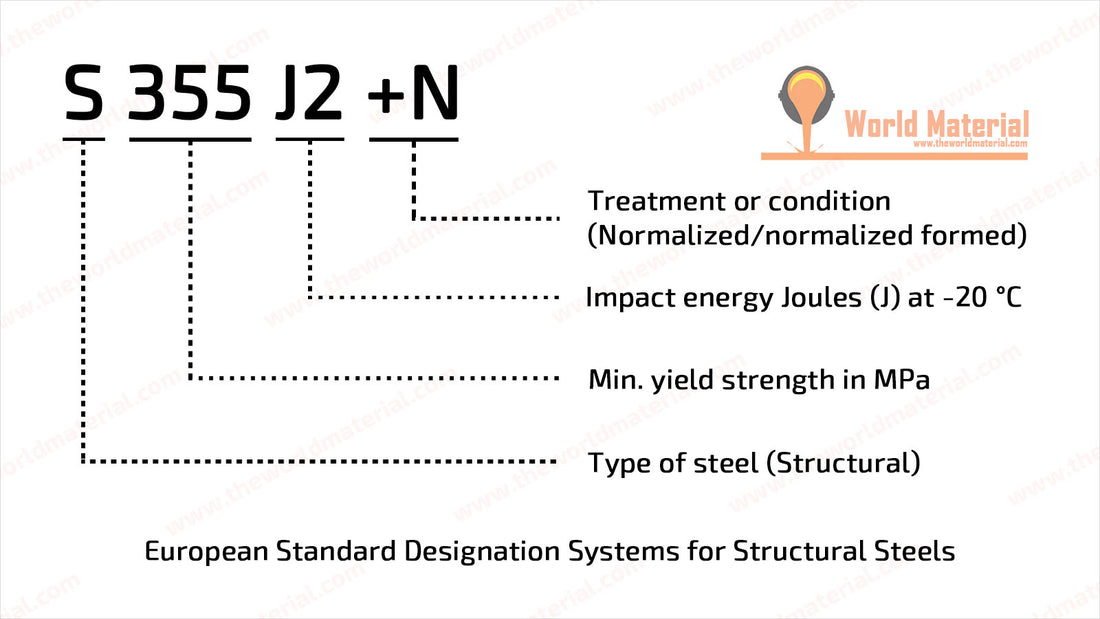

- The first letter indicates the type of steel,

- The following digits indicate the yield strength MPa;

- The 2 symbols immediately after the yield point value indicate the quality grade of the steel;

- The symbols immediately following the quality grade indicate characteristics/uses or treatment, and

- Finally, a plus sign (+) and a symbol indicate delivery/handling conditions, coatings or special requirements.

For example,

S235JRC+C Meaning :

- “S” is the abbreviation for structural steel.

- “235” refers to the yield strength in MPa.

- J indicates Joules (27 J)

- R is the abbreviation for Room temperature (20 °C).

- C stands for special cold forming (cold flanging, cold forming or cold drawing).

- “+C” indicates cold hardening.

S235JRC+C Meaning : Structural steel (S) with specified minimum yield strength of 235 MPa at room temperature, minimum impact energy of 27 J at room temperature of 20 °C (JR), suitable for cold flanging (C), delivery condition +C (cold hardened).

Meaning S355J2W : Structural steel (S) with specified yield strength ≥355 MPa at room temperature, impact energy ≥27 J at -20 °C (J2) and is weather resistant (W).

S355MC Meaning : Structural steel (S), thermomechanically rolled (M), with a specified minimum yield strength at room temperature of 355 MPa (355) and suitable for cold forming (C).

| Basic constituent symbols indicating quality grades of structural steel | |

|---|---|

| Symbol/Number | Meaning |

| s | Structural steel |

| 235 | Yield strength: 235 MPa |

| Jr. | Joules (27J) at room temperature (+20°C) |

| J0 | Joules (27J) at 0°C |

| J2 | Joules (27J) at -20°C |

| J3 | Joules (27J) at -30°C |

| J4 | Joules (27J) at -40°C |

| J5 | Joules (27J) at -50°C |

| J6 | Joules (27J) at -60°C |

| KR | Joules (40J) at room temperature (+20°C) |

| K0 | Joules (40J) at 0°C |

| K2 | Joules (40J) at -20°C |

| K3 | Joules (40J) at -30°C |

| K4 | Joules (40J) at -40°C |

| K5 | Joules (40J) at -50°C |

| K6 | Joules (40J) at -60°C |

| LR | Joules (60J) at room temperature (+20°C) |

| L0 | Joules (60J) at 0°C |

| L2 | Joules (60J) at -20°C |

| L3 | Joules (60J) at -30°C |

| L4 | Joules (60J) at -40°C |

| L5 | Joules (60J) at -50°C |

| L6 | Joules (60J) at -60°C |

| A | Precipitation hardening |

| M | Thermomechanically rolled |

| N | Normalized or rolled normalized |

| P | Quenched and tempered |

| W | Special cold forming (cold flanging, cold forming or cold drawing) |

| D | Hot dip coating |

| AND | Enameling |

| F | Forged |

| H | Hollow section |

| I | Low temperature |

| P | sheet piling |

| P | For the class with the highest phosphorus content (only in the case of class S355) |

| s | Shipbuilding |

| T | Tubes |

| W | Weather resistant (better resistance to atmospheric corrosion) |

| Symbols indicating the treatment of steel products | |

|---|---|

| Symbol | Meaning |

| +A | Soft annealed |

| +AC | annealed to obtain spheroidized carbides |

| +AR | as laminated (without any special lamination conditions and/or heat treatment) |

| +AT | solution annealed |

| +C | hardened cold work |

| +Cxxx | cold work hardened with a minimum tensile strength of xxx MPa |

| +CPxxx | cold work hardened with a minimum strength of 0.2% xxx MPa |

| +CR | cold rolled |

| +DC | delivery condition at the discretion of the manufacturer |

| +PF | treated with ferritic-pearlite structure and hardness range |

| +HC | hot rolled followed by cold hardening |

| +me | isothermally treated |

| +LC | ironed leather (tempered laminated or cold drawn) |

| +M | thermomechanically formed |

| +N | normalized or normalized formed |

| +NT | standardized and tempered |

| +P | hardened precipitation |

| +Q | wiped out |

| + quality control | air tempered |

| +QO | seasoned oil |

| +QT | Quenched and tempered |

| +QW | tempered water |

| +RA | annealed recrystallization |

| +S | treated for cold cutting |

| +SR | relieved stress |

| +T | temperate |

| +TH | hardness range treatment |

| +you | not treated |

| +WW | hot worked |

| Symbols for steel products indicating the type of coating | |

|---|---|

| Symbol | Meaning |

| +A | hot dip aluminum coating |

| +HOW | aluminum silicon alloy shell |

| +AZ | aluminum and zinc alloy coating (>50% Al) |

| +CE | electrolytic chromium/chromium oxide coating (ECCS) |

| +CU | copper plating |

| +IC | inorganic coating |

| +OC | organic coating |

| +S | hot dip tin coating |

| +SE | tin electrolytic coating |

| +T | hot-dip tin-lead alloy plating (terne) |

| +TE | tin and lead alloy electrolytic coating (terne) |

| +Z | hot dip zinc coating (galvanized) |

| +ZA | hot dip zinc and aluminum coating (>50% Zn) |

| +ZE | zinc electrolytic coating |

| +ZF | hot dip zinc iron coating (galvannealed) |

| +ZM | hot dip zinc and magnesium coating |

| +ZN | zinc and nickel alloy electrolytic coating |

| Symbols for steel products indicating special requirements | |

|---|---|

| Symbol | Meaning |

| +CH | core hardenability |

| +H | hardenability |

| +Z15 | through the thickness property; minimum area reduction = 15% |

| +Z25 | through the thickness property; minimum area reduction = 25% |

| +Z35 | through the thickness property; minimum area reduction = 35% |