SAE AISI 4140 alloy steel

SAE 4140 (AISI 4140 steel) is a Cr-Mo series (Chrome molybdenum series) low alloy steel, the material has high strength and hardenability, good toughness, small deformation during quenching, high creep resistance and long-lasting high temperature resistance .

Uses of 4140 Steel

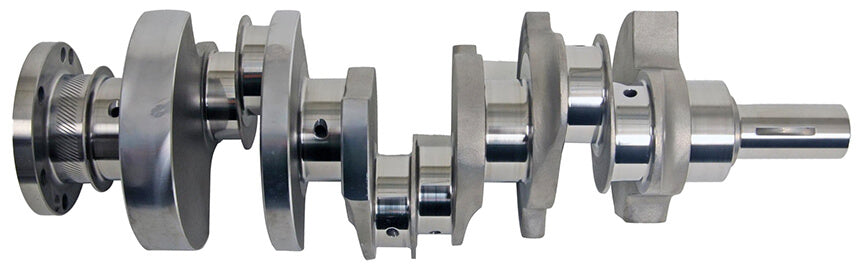

AISI SAE 4140 alloy steel can be made into round steel bar, flat and square steel bar, steel plate, steel tube and has many uses in aerospace, oil and gas and automotive industries, typical uses are vessels thin-walled pressure shafts, forged gears and shafts (motor shafts, pump shafts, hydraulic shafts, etc.), spindles (lathe spindles, milling spindles, etc.), collars, clamps, high-strength screws, bonnet valves, screws, nuts, worms, clamps, torsion bars and various carbureted parts.

Datasheet and specifications

Below are 4140 alloy steel data sheets including chemical composition, properties and equivalent chart, etc.

AISI SAE 4140 Chemical Composition

The table below lists the chemical composition of AISI 4140.

| AISI SAE 4140 Chemical Composition (%) | ||||||||

| Steel (UNS) | W | Yes | Mn | P(≤) | S (≤) | Cr | Mo | No |

| 4140 (G41400) | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.040 | 0.80-1.10 | 0.15-0.25 | – |

Mechanical Properties of AISI 4140 Steel

The mechanical properties of material 4140 are given in the table below.

| Steel | Tensile strength, Mpa (ksi) | Yield strength, Mpa (ksi) | Elongation by 50 mm (2 in.), % | Area reduction, % | Hardness (HB) | Sample diameter | Conditions |

| AISI4140 | 1020 (148) | 655 (95) | 17.7 | 46.8 | 302 | 25.4 mm (1 in.) | Normalized to 870°C (1600°F) |

| 655 (95) | 414 (60) | 25.7 | 56.9 | 197 | Annealed at 815°C (1500°F) | ||

| 1075 (156) | 986 (143) | 15.5 | 56.9 | 311 | Water tempered to 845°C (1550°F) and tempered to 540°C (1000°F) |

SAE 4140 Physical Properties

Notes: 10 -6 /K = 10 -6 .K -1 = (µm/m)/°C

| Material 4140 coefficients of linear thermal expansion | ||

| Temperature, °C (°F) | Value (10 -6 /K) | Treatment or condition |

| 20-100 (68-212) | 12.2 | Hardened, tempered oil |

| 20-200 (68-392) | 12.6 | |

| 20-400 (68-752) | 13.6 | |

| 20-600 (68-1112) | 14.5 | |

| 4140 thermal conductivity | ||

| Value (W/m·K) | Temperature, °C (°F) | Treatment or condition |

| 42.7 | 100 (212) | Hardened and temperate |

| 42.3 | 200 (392) | |

| 37.7 | 400 (752) | |

| 33.1 | 600 (1112) | |

| AISI/SAE 4140 Specific Heat | ||

| Value (J/Kg·K) | Temperature, °C (°F) | Treatment or condition |

| 473 | 20-200 (68-392) | Hardened and temperate |

| 519 | 20-400 (68-752) | |

| 561 | 20-600 (68-1112) | |

| Electrical Resistivity Mateiral 4140 | ||

| Value (μΩ·m) | Temperature, °C (°F) | Treatment or condition |

| 0.22 | 20 (68) | Hardened and temperate |

| 0.26 | 100 (212) | |

| 0.33 | 200 (392) | |

| 0.48 | 400 (752) | |

| 0.65 | 600 (1112) | |

Heat Treatment of 4140 Material Steel

The following table shows the heat treatment of AISI 4140 steel, Rockwell hardness.

| 4140 Material Heat Treatment | Temperature, °C (°F) | Hardness of 4140 steel | Cooling/Agent |

| Normalizing | 870 (1600) | 302 HB | Air |

| girdling | 790-845 (1455-1555) | 197 HB | Oven cooling |

| Tempera | 830-845 (1525-1555) | Oil | |

| Tempering (2 hours) | 205 (400) | 58 HRC | Oil hardening |

| 260 (500) | 54 HRC | ||

| 315 (600) | 50 HRC | ||

| 370 (700) | 47 HRC | ||

| 425 (800) | 45 HRC | ||

| 480 (900) | 40 HRC | ||

| 540 (1000) | 35 HRC | ||

| 595 (1100) | 33 HRC | ||

| 650 (1200) | 28 HRC |

Normalizing

4140 alloy steel is normally standardized at 870°C (1600°F) and must be cooled to a specified temperature in still air.

Spheroidizing Annealing

For spheroidizing annealing of 4140 alloy steel, it needs heat treatment at 749°C (1380°F) followed by slow cooling to 666°C (1230°F) at a rate of 6°C (10°F) /hour, or rapid cooling to 675 °C (1250 °F) for isothermal annealing.

Complete Annealing

Heat treating at 845°C (1555°F), slow cooling at 755°C (1390°F) at a rate of 14°C (25°F)/hour to 665°C (1230°F), or rapid cooling at 675°C (1250°F) for 5 hours of isothermal annealing.

Temperament

The tempering temperature of 4140 alloy steel can be 204-649°C (400-1200°F) after normalizing and oil quenching, and the corresponding Rockwell hardness can be obtained.

Forging

The forging temperature of material 4140 is about 1232 °C (2250 °F).

4140 Steel Welding

All common arc welding processes such as (SAW, SMAW, FCAW, GMAW, GTAW) can be used to weld 4140 alloy steel, but to avoid cracking, it must be preheated to 170-350°C ( 350-650°F) before welding, the interpass preheat temperature depends on the steel section thickness.

Equivalent Material

The material equivalent to AISI 4140 is listed in the table below.

| Material equivalent to AISI 4140 | |||||||||

| USA | European Union | China | Japan | ISO | |||||

| Standard | Note (UNS) | Standard | Class (Steel Number) | Standard | Note | Standard | Note | Standard | Note |

| AISI-SAE; ASTM A29/A29M |

4140 (G41400) | EN 10083-3 | 42CrMo4 (1.7225) | GB/T 3077 | 42CrMo | JISG 4105 | SCM440 | ||