AISI H13 tool steel

AISI H13 steel is a 5% Cr ultra-high strength tool steel alloy with higher molybdenum and vanadium content. Molybdenum provides excellent toughness and high hardenability; Vanadium results in a greater degree of dispersion of hard vanadium carbides, resulting in greater wear resistance.

H13 tool steel is a secondary hardening steel. It has good tempering resistance, good thermal fatigue resistance and excellent heat cracking resistance, and maintains high hardness and strength at elevated temperatures. It is deep hardening and has a very high toughness, which allows large sections to be hardened by air cooling.

Hot work tools made from H13 material can be safely water cooled in hot work where thermal shock cracking is not a problem. Its resistance to thermal fatigue, erosion and wear makes it the preferred mold material for aluminum and magnesium die castings as well as many other hot work applications. However, H13 metal is subject to hydrogen embrittlement and can be nitrided for greater wear resistance.

AISI H13 steel properties

The following data sheets summarize the properties of H13 steel such as chemical composition, physical and mechanical properties, etc.

Chemical composition

| Chemical composition, % | |||||||||

| Standard | AISI (UNS) | W | Yes | Mn | P, ≤ | S, ≤ | Cr | Mo | V |

| ASTM A681 | H13 (T20813) | 0.32-0.45 | 0.80-1.25 | 0.20-0.60 | 0.030 | 0.030 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

Note: The manganese limit is ≤ 1.0% for resulfurized H13.

Physical properties

The physical properties of H13 material such as density, specific heat capacity and thermal properties, modulus of elasticity are given in the table below.

| Physical properties | Metric | Imperial |

| Density | 7.76g/cm3 | 0.280 lb/in3 |

| Specific heat capacity | 460 J/kg·K (20 °C) | 0.11 Btu/lb°F (68°F) |

| Elastic modulus (Modulus of elasticity) | 193 GPa | 28×10 6 psi |

| 186 GPa (190°C) | 27× 106 psi (375°F) | |

| 172 GPa (400°C) | 25× 106 psi (750°F) | |

| Thermal conductivity | 32.0 W/m·K (20 °C) | 18.5 Btu/ft·h·°F (68°F) |

| 33.0 W/m·K (190 °C) | 19.1 Btu/ft·h·°F (375°F) | |

| 34.0 W/m·K (400 °C) | 19.7 Btu/ft·h·°F (750°F) | |

| Coefficient of thermal expansion (CTE) | 10.4μm/m (20-100°C) | 5.8 μin./in.°F (70-200 °F) |

| 11.5μm/m (20-200°C) | 6.4 μin./in.°F (70-400 °F) | |

| 12.2μm/m (20-425°C) | 6.8 μin./in.°F (70-800 °F) | |

| 12.4μm/m (20-540°C) | 6.9 μin./in.°F (70-1000 °F) | |

| 13.1μm/m (20-650°C) | 7.3 μin./in.°F (70-1200 °F) |

Mechanical Properties of H13 Steel

Typical longitudinal mechanical properties at room temperature of tempered H13 steel bars with different hardness levels.

Round bars, quenched in oil from 1010 °C (1850 °F) and double tempered, 2+2 hours at the indicated temperature.

| Quenching temperature, °C (°F) | Tensile strength, MPa (ksi) | Yield strength, MPa (ksi) | Elongation in 4D standard length, % | Area reduction, % | Hardness, HRC | V-Notch Charpy Impact, J (ft·lbf) |

| 527 (980) | 1960 (284) | 1570 (228) | 13.0 | 46.2 | 52 | 16 (12) |

| 555 (1030) | 1835 (266) | 1530 (222) | 13.1 | 50.1 | 50 | 24 (18) |

| 575 (1065) | 1730 (251) | 1470 (213) | 13.5 | 52.4 | 48 | 27 (20) |

| 593 (1100) | 1580 (229) | 1365 (198) | 14.4 | 53.7 | 46 | 28.5 (21) |

| 605 (1120) | 1495 (217) | 1290 (187) | 15.4 | 54.0 | 44 | 30 (22) |

Short-term longitudinal tensile properties of H13 tool steel bar

Oil quenched at 1010°C (1850°F) and tempered twice to stated hardness.

| Hardness at room temperature, HRC | Test temperature, °C (°F) | Tensile strength, MPa (ksi) | Yield strength, MPa (ksi) | Elongation in 4D standard length, % | Area reduction, % |

| 52, tempering 2+2 h at 527 °C (980 °F). | 425 (800) | 1620 (235) | 1240 (180) | 13.7 | 50.6 |

| 540 (1000) | 1305 (189) | 1000 (145) | 13.9 | 54.0 | |

| 595 (1100) | 1020 (148) | 825 (120) | 17.5 | 65.4 | |

| 650 (1200) | 450 (65) | 340 (49) | 28.9 | 88.9 | |

| 48, tempered 2+2 h at 575 °C (1065 °F). | 425 (800) | 1400 (203) | 1150 (167) | 15.0 | 59.9 |

| 540 (1000) | 1160 (168) | 960 (139) | 17.1 | 62.4 | |

| 595 (1100) | 940 (136) | 750 (109) | 18.0 | 68.5 | |

| 650 (1200) | 455 (66) | 350 (51) | 33.6 | 89.0 | |

| 44, tempering 2+2 h at 605 °C (1120 °F). | 425 (800) | 1200 (174) | 1005 (146) | 17 | 64.1 |

| 540 (1000) | 995 (144) | 820 (119) | 20.6 | 70.0 | |

| 595 (1100) | 827 (120) | 690 (100) | 22.6 | 74.0 | |

| 650 (1200) | 450 (65) | 350 (51) | 28.4 | 87.6 |

Longitudinal impact properties of H13 tool steel bar quenched at different temperatures

Air cooled from 1010 °C (1850 °F) and double tempered, 2+2 hours at the indicated temperature.

| Quenching Temperature | Hardness, HRC, at room temperature | Charpy quench V-notch impact energy [J(ft·lbf)] at test temperature | ||||

| °C (°F) | -73°C (-100°F) | 21°C (70°F) | 260°C (500°F) | 540°C (1000°F) | 595°C (1100°F) | |

| 524 (975) | 54 | 7 (5) | 14 (10) | 27 (20) | 31 (23) | – |

| 565 (1050) | 52 | 7 (5) | 14 (10) | 30 (22) | 34 (25) | 34 (25) to 565 °C (1050 °F) |

| 607 (1125) | 47 | 8 (6) | 24 (18) | 41 (30) | 45 (33) | 43 (32) |

Hardness range of H13 steel

The hardness range of H13 steel is 28-53 HRC, varies with tempering temperature, all samples are air cooled from 1025°C (1875°F) and temperature tempered for 2 hours.

The hardness range of H13 steel is 28-53 HRC, varies with tempering temperature, all samples are air cooled from 1025°C (1875°F) and temperature tempered for 2 hours.

Heat treatment

H13 metal heat treatment

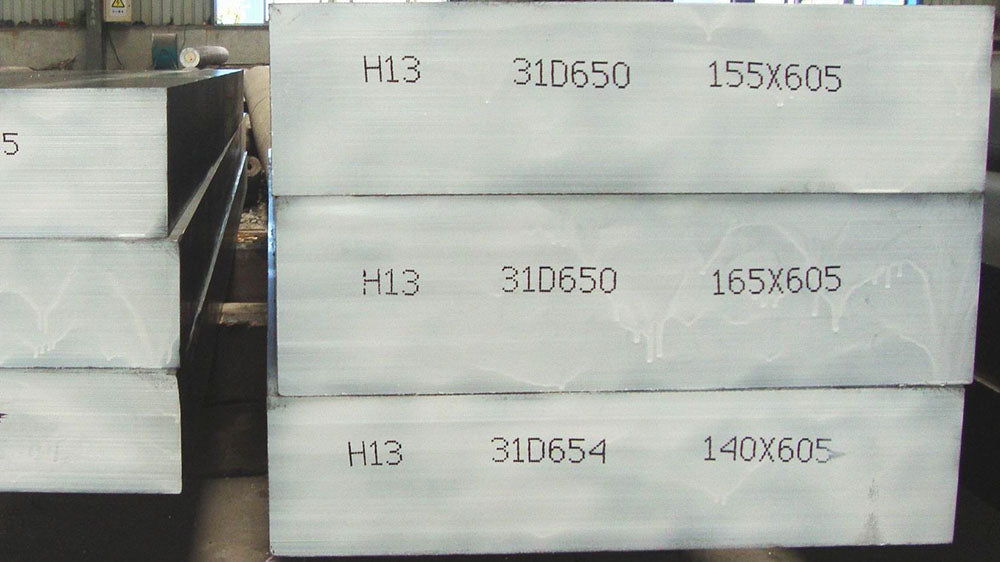

Forms

H13 material is available as rods, bars, billets and forgings. Typical thermal processing applications include die casting dies, forging dies, extrusion dies, inserts, plungers, cores, ejector pins, sleeves, slides, dummy blocks, mandrels and hot shears. Other structural and tooling applications include beams, shafts, punches, torsion bars, covers and ratchets.

AISI H13 steel equivalent material

The equivalent material of AISI H13 tool steel is listed in the table below, including European EN, ISO, German DIN, Chinese GB and Japanese JIS standards, etc.

| AISI H13 steel equivalent material | |||||||||||||||||||

| USA | European Union | ISO | Germany | Japan | China | Australia | India | Russia | Korea | ||||||||||

| Standard | Steel (UNS) | Standard | Steel Name (Material Number) | Standard | Designation | Standard | Steel Name (Material Number) | Standard | Steel Grade | Standard | Steel Grade | Standard | Note | Standard | Note | Standard | Note | Standard | Note |

| AISI, SAE; ASTM A681 |

H13 (T20813) | EN ISO 4957 | X40CrMoV5-1 (1.2344) | ISO 4957 | X40CrMoV5-1 | DIN EN ISO 4957; DIN 17350 |

X40CrMoV5-1 (1.2344) | JIS G4404 | SKD61 | GB/T 1299 | 4Cr5MoSiV1 | ||||||||

1comment

Boa tarde,

Favor cotar conforme abaixo,

2 PÇS DE AÇO H13 MEDIDA=20X98X126MM (SOBREMETAL)