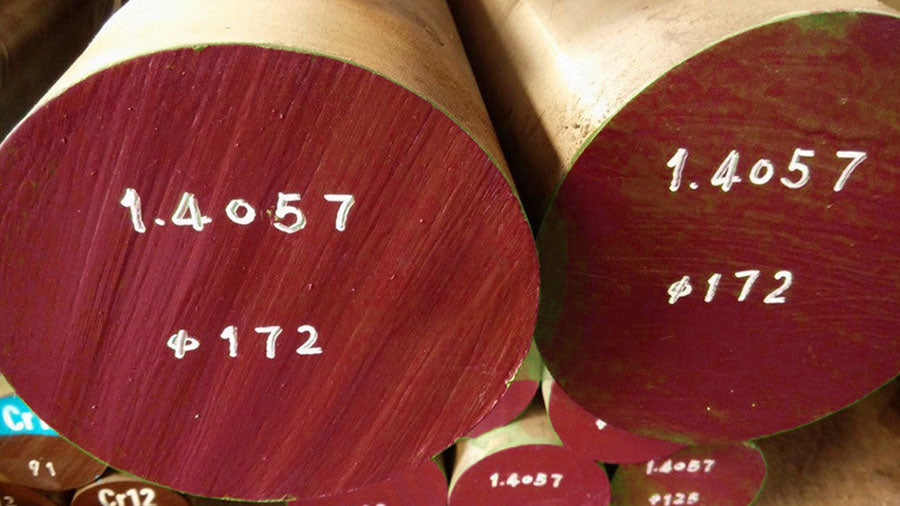

DIN EN 1.4057 Stainless Steel (Material X17CrNi16-2)

DIN EN 1.4057 stainless steel (material X17CrNi16-2) is a nickel-containing martensitic stainless steel, which has better corrosion resistance and mechanical properties than straight chromium stainless steel.

The higher carbon content causes it to tend to form chromium carbide and therefore the formation of chromium-free areas makes the 1.4057 material susceptible to intergranular corrosion. However, polishing the surface can improve its corrosion resistance.

Properties and specifications of DIN 1.4057 steel

The properties and specifications of DIN 1.4057 stainless steel are summarized in the following tables, including chemical composition, mechanical properties, hardness, heat treatment, etc.

Chemical composition

The chemical composition of the material X17CrNi16-2 is listed in the following table based on casting analysis.

| Chemical composition, % | ||||||||

| Standard | Designation (Steel Number) | W | Yes, ≤ | Mn, ≤ | P, ≤ | S, ≤ | Cr | No |

| EN 10088-2; EN 10088-3 |

X17CrNi16-2 (1.4057) | 0.12-0.22 | 1.00 | 1.50 | 0.040 | 0.015 | 15.0-17.0 | 1.50-2.50 |

Notes: For 1.4057 stainless steel bars, rebars, wires, profiles, bright products and related semi-finished products, the S content is ≤0.030%. A specific range of sulfur content can provide specific performance improvements. For machinability, it is recommended and permitted to control the sulfur content between 0.015% and 0.030%. For weldability, it is recommended and permitted to control the sulfur content between 0.008% and 0.030%. To improve polishing performance, it is recommended to control the sulfur content to a maximum of 0.015%.

Physical properties

The physical properties of DIN EN 1.4057 stainless steel are listed in the table below, such as density, melting point, specific heat, electrical resistivity, modulus of elasticity (modulus of elasticity), thermal conductivity and coefficient of thermal expansion (CTE).

Grades:

- 10 -6 ·K -1 = 10 -6 /K

- 1Ω mm²/m = 1 μΩ m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1kN/mm2

- 1 MPa = 1 N/mm2

| Physical properties | |

| Density, g/cm3 (lb/in3) | 7.7 (0.278) |

| Magnetic | Yes |

| Specific heat capacity, J/(Kg·K) | 460 to 20°C (68°F) |

| Electrical resistivity, μΩ·m | 0.70 to 20°C (68°F) |

| Modulus of elasticity (Elastic Modulus), Gpa (10 3 ksi) | 215 (31.2) at 20°C (68°F) |

| 212 (30.7) at 100°C (212°F) | |

| 205 (29.7) to 200 °C (392 °F) | |

| 200 (29) to 300°C (572°F) | |

| 190 (27.5) to 400 °C (752 °F) | |

| Thermal conductivity, (W/m·K) | 25 to 20°C (68°F) |

| Average coefficient of thermal expansion, (10 -6 /K) | 10.0 to 20-100°C (68-212°F) |

| 10.5 to 20-200°C (68-392°F) | |

| 10.5 to 20-300°C (68-572°F) | |

| 10.5 to 20-400°C (68-752°F) | |

DIN EN 1.4057 Mechanical Properties of Stainless Steel

The mechanical properties of DIN EN 1.4057 stainless steel are given in the data sheet below, including tensile strength, yield strength, elongation, area reduction, Brinell and Rockwell hardness, etc.

| Room temperature mechanical properties of 1.4057 stainless steel heat treated under conditions 1C, 1E, 1D, 1X, 1G and 2D | ||||||||

| Standard | Steel grade (steel number) | Thickness | ||||||